Application rate sensor calibration, Calibrating the liquid application, Application rate sensor calibration -3 – TeeJet ARC-6000 User Manual

Page 13: Calibrating the liquid application -3

2-3

98-0501

Rev.- 1

ARC 6000

CE & S

TANDARD

V

ERSION

A. Set the console to the following positions;

Power

ON

Mode Selector

SET- UP

Display Selector

IMPL. WIDTH

All Boom Solenoid Switches (external)

OFF

The display will cycle through each boom position (1 through 9) and display its current width in inches.

B. As each boom position appears on the display, use the INC/DEC switch to set the display to the number of inches

covered by that boom. Repeat for each section.

NOTE: Individual boom widths are entered in inches. For example; for a liquid boom with 7 nozzles on

30" spacings, enter 180 for that boom. There is no need to convert to feet, the control console does that

automatically when it is switched back to the OPERATE MODE.

C. Set all unused boom sections to a width of zero “0” inches. This will insure that an accidental boom switch ON will not

affect the control console.

D. The boom width is now set. Turn all boom switches to the ON position and return to the OPERATE Mode, the new

total boom width will be displayed in feet. If this does not agree with your total applicator width, check the individual

boom widths, (steps B and C).

2.6. APPLICATION RATE SENSOR CALIBRATION

The control console must be calibrated for the flowmeter, pressure sensor, or rate sensor being used. The calibration number

required by the control console is the actual number of electrical pulses per unit volume generated by the sensor, or, for the pressure

sensor, the gallons per acre rating of the nozzles being used. If you have any doubts as to the accuracy of the flow sensor

readings, a field calibration/catch test should be performed using the actual product solution. (see section 2.6.1.4)

2.6.1. CALIBRATING THE LIQUID APPLICATION

Verify that the correct application program has been selected (see section 2.1.)!

If in the Psi mode, check the correction factor. It should be set to 1.0 during the calibration routine. To check the correction

factor, set the Display Selector to APPLICATION RATE, set the Mode Selector switch to SETUP. Use the INC/DEC

switch to set the correction factor if necessary.

2.6.1.1. DETERMINING THE FLOWMETER INITIAL CALIBRATION NUMBER

FLOWMETERS are calibrated for water at the factory. This number is accurate enough for most applications. However, the

actual flow characteristics may differ due to plumbing or other factors.

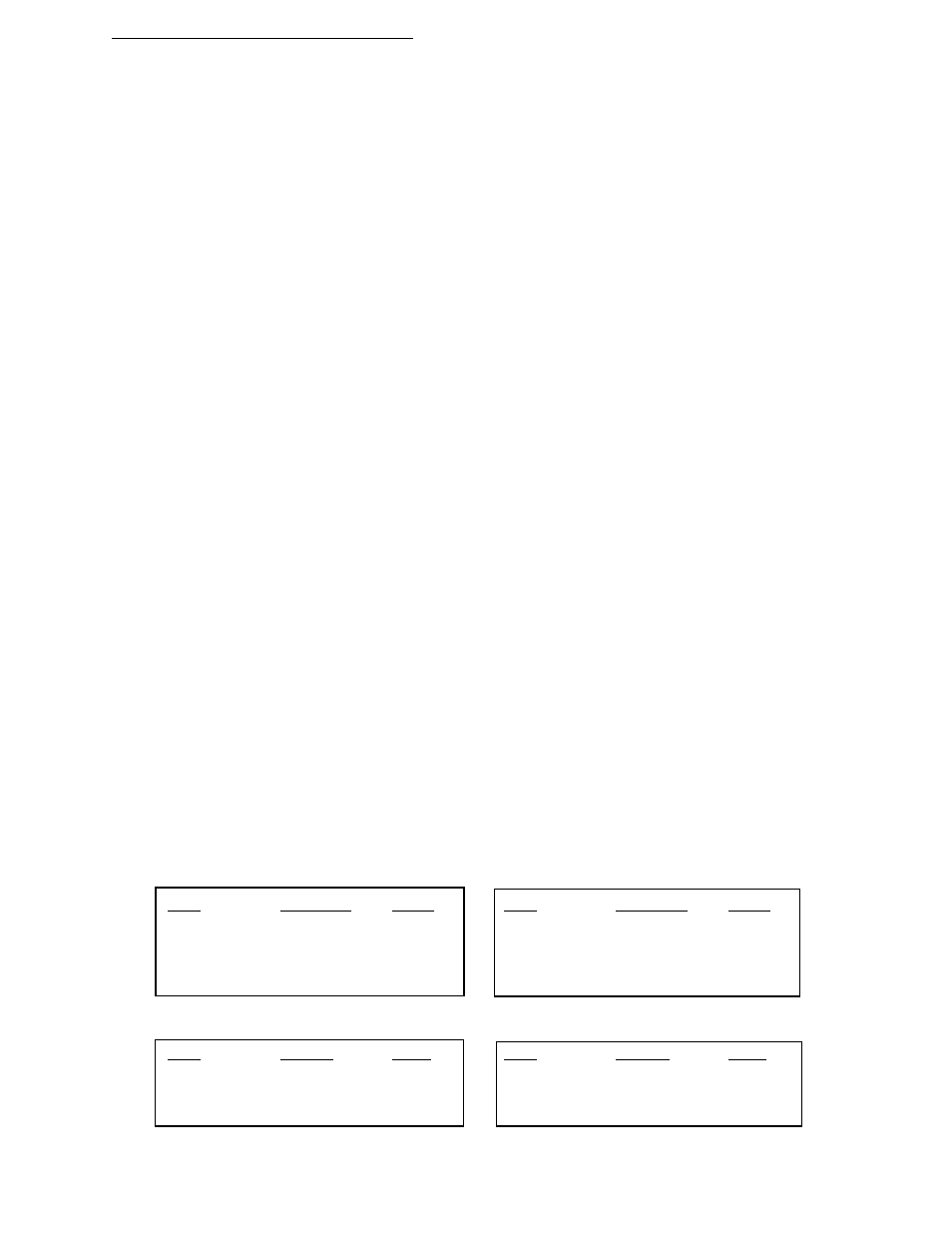

Standard Flowmeters

SIZE

SUPPLIER

CAL.#

SIZE

SUPPLIER

CAL.#

.75 inch

(Mid-Tech)

396.9

3.00 inch

(Mid-Tech)

5.0

1.00 inch

(Mid-Tech)

153.1

1.50 inch

(Mid-Tech)

38.8

1.25 inch

(Raven)

75.0*

2.00 inch

(Mid-Tech)

23.8

3.00 inch

(Raven)

16.4*

Mid-Tech Rapid Check Flowmeters

SIZE

RANGE

CAL#

SIZE

RANGE

CAL#

1.00 inch

0.75 - 5 gpm

3200

1.50 inch

2.5 - 25 gpm

612.4

1.00 inch

2.5 - 16 gpm

800

1.50 inch

2.6 - 53 gpm

361.9

2.00 inch

20.0 - 195 gpm

94.5

* Raven flow meters, use the factory calibration number divided by 10. All other flowmeters use the manufacturers'

supplied information regarding the pulses per gallon (usually provided on a tag on the flowmeter).