Table 30 — troubleshooting (cont) – Carrier AQUAZONE RVC User Manual

Page 42

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500007-01

Printed in U.S.A.

Form 50R-5SI

Pg 42

6-07

Replaces: 50R-4SI

Book 1

4

Tab

5a 5a

Copyright 2007 Carrier Corporation

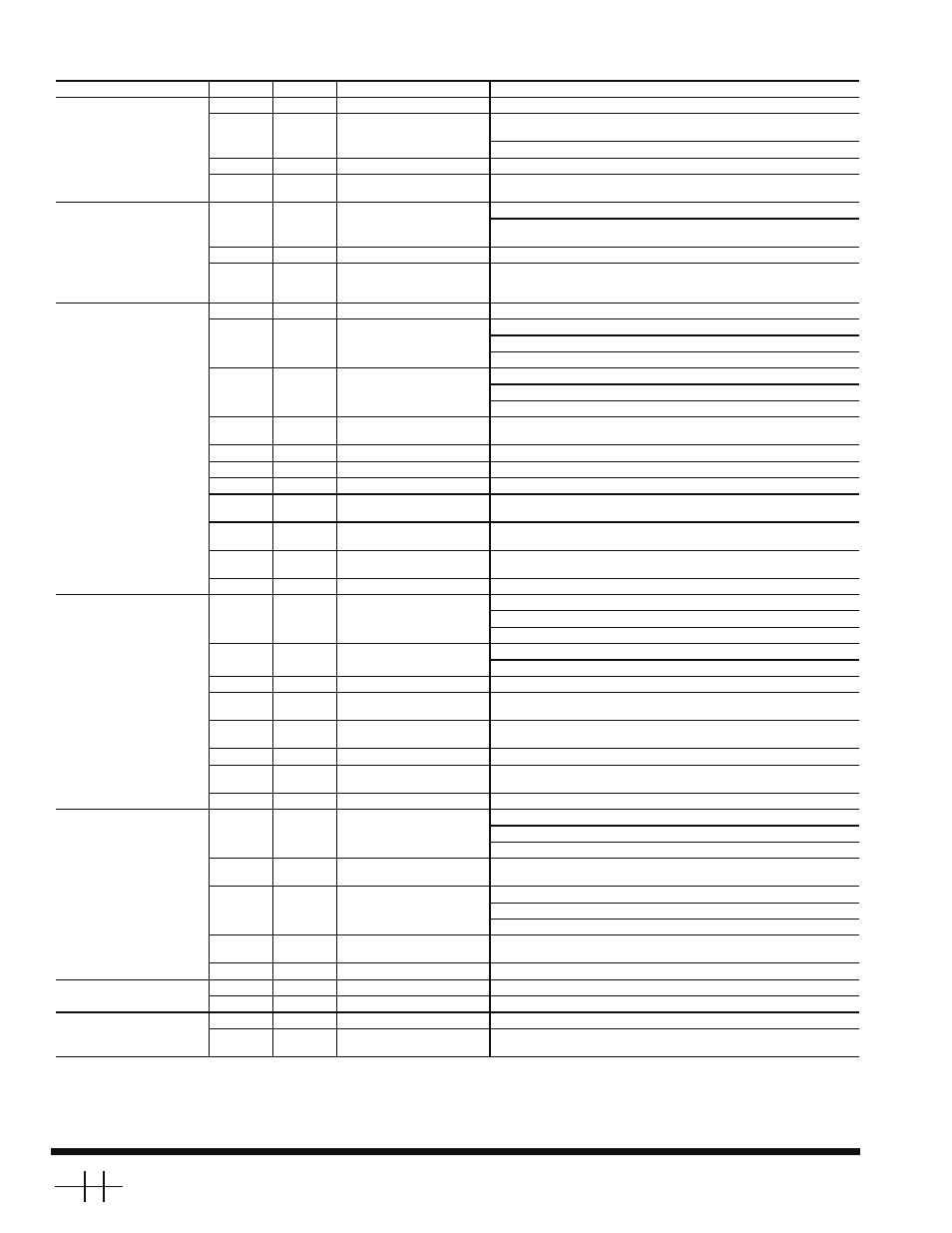

Table 30 — Troubleshooting (cont)

LEGEND

RV — Reversing Valve

FAULT

HEATING

COOLING

POSSIBLE CAUSE

SOLUTION

Only Compressor Runs

X

X

Thermostat wiring

Check G wiring at heat pump. Jumper G and R for fan operation.

X

X

Fan motor relay

Jumper G and R for fan operation. Check for line voltage across BR

contacts.

Check fan power enable relay operation (if present).

X

X

Fan motor

Check for line voltage at motor. Check capacitor.

X

X

Thermostat wiring

Check Y and W wiring at heat pump. Jumper Y and R for compressor

operation in test mode.

Unit Does Not Operate in

Cooling

X

Reversing valve

Set for cooling demand and check 24 VAC on RV coil and at control.

If RV is stuck, run high pressure up by reducing water flow and while

operating engage and disengage RV coil voltage to push valve.

X

Thermostat setup

Check for 'O' RV setup not 'B'.

X

Thermostat wiring

Check O wiring at heat pump. Check RV to ensure the valve is chang-

ing over from heating and cooling modes. A 'click' should be heard

when the RV changes modes.

Insufficient Capacity/

Not Cooling or Heating

Properly

X

X

Dirty filter

Replace or clean.

X

Reduced or no airflow in

heating

Check for dirty air filter and clean or replace.

Check fan motor operation and airflow restrictions.

External static too high. Check blower Tables 8-13.

X

Reduced or no airflow in

cooling

Check for dirty air filter and clean or replace.

Check fan motor operation and airflow restrictions.

External static too high. Check blower Tables 8-13.

X

X

Leaky ductwork

Check supply and return air temperatures at the unit and at distant duct

registers if significantly different, duct leaks are present.

X

X

Low refrigerant charge

Check superheat and subcooling Table 21.

X

X

Restricted metering device

Check superheat and subcooling Table 21. Replace.

X

Defective reversing valve

Manually check the four-way valve to ensure all valves are operational.

X

X

Thermostat improperly

located

Check location and for air drafts behind thermostat.

X

X

Unit undersized

Recheck loads and sizing check sensible cooling load and heat pump

capacity.

X

X

Scaling in water heat

exchanger

Check for scale (water deposits) and clean if necessary.

X

X

Inlet water too hot or cold

Check load, loop sizing, loop backfill, ground moisture.

High Head Pressure

X

Reduced or no airflow in

heating

Check for dirty air filter and clean or replace.

Check fan motor operation and airflow restrictions.

External static too high. Check blower Tables 8-13.

X

Reduced or no water flow in

cooling

Check pump operation or valve operation/setting.

Check water flow adjust to proper flow rate. See Table 20.

X

Inlet water too hot

Check load, loop sizing, loop backfill, ground moisture.

X

Air temperature out of range

in heating

Bring return air temperature within design parameters.

X

Scaling in water heat

exchanger

Check for scale (water deposits) and clean if necessary.

X

X

Unit overcharged

Check superheat and subcooling. Reweigh in charge.

X

X

Non-condensables in

system

Evacuate the refrigerant, recharge the system, and then weigh the new

refrigerant charge.

X

X

Restricted metering device

Check superheat and subcooling per Table 21. Replace.

Low Suction Pressure

X

Reduced water flow in

heating

Check pump operation or water valve operation/setting.

Plugged strainer or filter. Clean or replace.

Check water flow adjust to proper flow rate.

X

Water temperature out of

range

Bring water temperature within design parameters.

X

Reduced airflow in cooling

Check for dirty air filter and clean or replace.

Check fan motor operation and airflow restrictions.

External static too high. Check blower Tables 8-13.

X

Air temperature out of range Too much cold vent air. Bring entering air temperature within design

parameters.

X

X

Insufficient charge

Check for refrigerant leaks.

Low Discharge Air

Temperature in Heating

X

Too high airflow

Check blower Tables 8-13.

X

Poor performance

See 'Insufficient Capacity'.

High Humidity

X

Too high airflow

Check blower Tables 8-13.

X

Unit oversized

Recheck loads and sizing check sensible cooling load and heat pump

capacity.