Operating limits, Scroll compressor rotation, Unit start-up cooling mode – Carrier AQUAZONE RVC User Manual

Page 33

33

Operating Limits

ENVIRONMENT — This equipment is designed for indoor

installation ONLY. Extreme variations in temperature, hu-

midity and corrosive water or air will adversely affect the

unit performance, reliability and service life.

POWER SUPPLY — A voltage variation of ± 10% of

nameplate utilization voltage is acceptable.

UNIT STARTING CONDITIONS — Depending on the

model, units start and operate in an ambient temperature of

45 F with entering-air temperature at 40 F or 50 F, entering-

water temperature at 20 F or 50 F and with both air and water at

the flow rates used.

NOTE: These operating limits are not normal or continuous

operating conditions. Assume that such a start-up is for the

purpose of bringing the building space up to occupancy

temperature. See Tables 18 and 19 for operating limits.

1. Restore power to system.

2. Turn thermostat fan position to ON. Blower should

start.

3. Balance airflow at registers.

4. Adjust all valves to the full open position and turn on

the line power to all heat pump units.

5. Operate unit in the cooling cycle. Refer to Tables 18

and 19 for unit operating limits.

NOTE: Three factors determine the operating limits of a

unit: (1) entering-air temperature, (2) water temperature and

(3) ambient temperature. Whenever any of these factors are

at a minimum or maximum level, the other two factors must

be at a normal level to ensure proper unit operation. See

Tables 18 and 19.

Scroll Compressor Rotation —

It is important to

be certain compressor is rotating in the proper direction. To

determine whether or not compressor is rotating in the prop-

er direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge

pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge

pressure does not rise to normal levels:

1. Turn off power to the unit. Install disconnect tag.

2. Reverse any two of the unit power leads.

3. Reapply power to the unit and verify pressures are correct.

The suction and discharge pressure levels should now move

to their normal start-up levels.

When the compressor is rotating in the wrong direction, the

unit makes more noise and does not provide cooling.

After a few minutes of reverse operation, the scroll com-

pressor internal overload protection will open, thus activating

the unit lockout. This requires a manual reset. To reset, turn the

thermostat on and then off.

NOTE: There is a 5-minute time delay before the compressor

will start.

Unit Start-Up Cooling Mode

1. Adjust the unit thermostat to the warmest position.

Slowly reduce the thermostat position until the compres-

sor activates.

2. Check for cool air delivery at unit grille a few minutes

after the unit has begun to operate.

3. Verify that the compressor is on and that the water flow

rate is correct by measuring pressure drop through the

heat exchanger using P/T plugs. See Table 20. Check the

elevation and cleanliness of the condensate lines; any

dripping could be a sign of a blocked line. Be sure the

condensate trap includes a water seal.

4. Check the temperature of both supply and discharge wa-

ter. Compare to Table 21. If temperature is within range,

proceed. If temperature is outside the range, check the

cooling refrigerant pressures in Table 21.

5. Check air temperature drop across the coil when com-

pressor is operating. Air temperature drop should be

between 15 and 25 F.

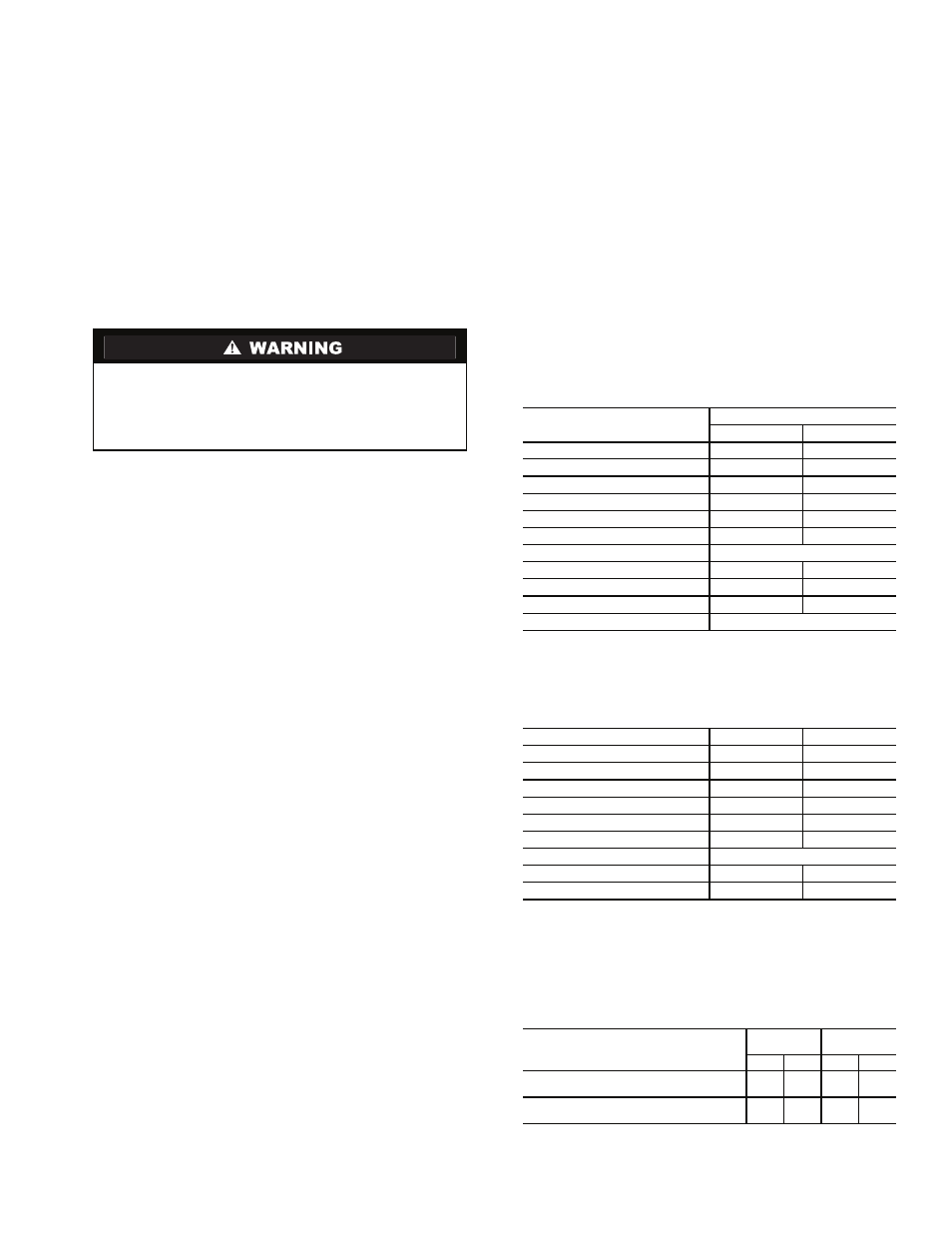

Table 18 — Operating Limits — 50RHC,RVC Units

LEGEND

Table 19 — Operating Limits —

50RHR,RHS,RVR,RVS,RDS Units

LEGEND

NOTE: Value in heating column is dry bulb only. Any wet bulb read-

ing is acceptable.

Table 20 — Water Temperature Change

Through Heat Exchanger

When the disconnect switch is closed, high voltage is

present in some areas of the electrical panel. Exercise

caution when working with the energized equipment.

Failure to heed this warning could lead to personal

injury.

AIR LIMITS

50RHC,RVC

Cooling

Heating

Min. Ambient Air – db

45 F

45 F

Rated Ambient Air – db

80.6 F

68 F

Max. Ambient Air – db

110 F

85 F

Min. Entering Air – db/wb

70/61 F

50 F

Rated Entering Air – db/wb

80.6/66.2 F

68 F

Max. Entering Air – db/wb

95/76 F

80 F

WATER LIMITS

Min. Entering Water

50 F

50 F

Normal Entering Water

60-90 F

60-70 F

Max. Entering Water

110 F

90 F

Normal Water Flow

2.5-3.0 gpm per ton

db — Dry Bulb

wb — Wet Bulb

AIR LIMITS

COOLING (F)

HEATING (F)

Min. Ambient Air

45

45

Rated Ambient Air

80

70

Max. Ambient Air

100

85

Min. Entering Air

50

40

Rated Entering Air db/wb

80/67

70

Max. Entering Air db/wb

110/83

80

WATER LIMITS

Min. Entering Water

30

20

Normal Entering Water

50-90

30-60

db — Dry Bulb

wb — Wet Bulb

WATER FLOW RATE (GPM)

COOLING

RISE (F)

HEATING

DROP (F)

Min

Max

Min

Max

For Closed Loop: Ground Source or

Cooling/Boiler Systems at 3 gpm/ton

9

12

4

8

For Open Loop: Ground Water Systems at

1.5 gpm/ton

20

26

10

17