Step 4 — mounting the unit, Step 5 — duct system – Carrier AQUAZONE RVC User Manual

Page 15

15

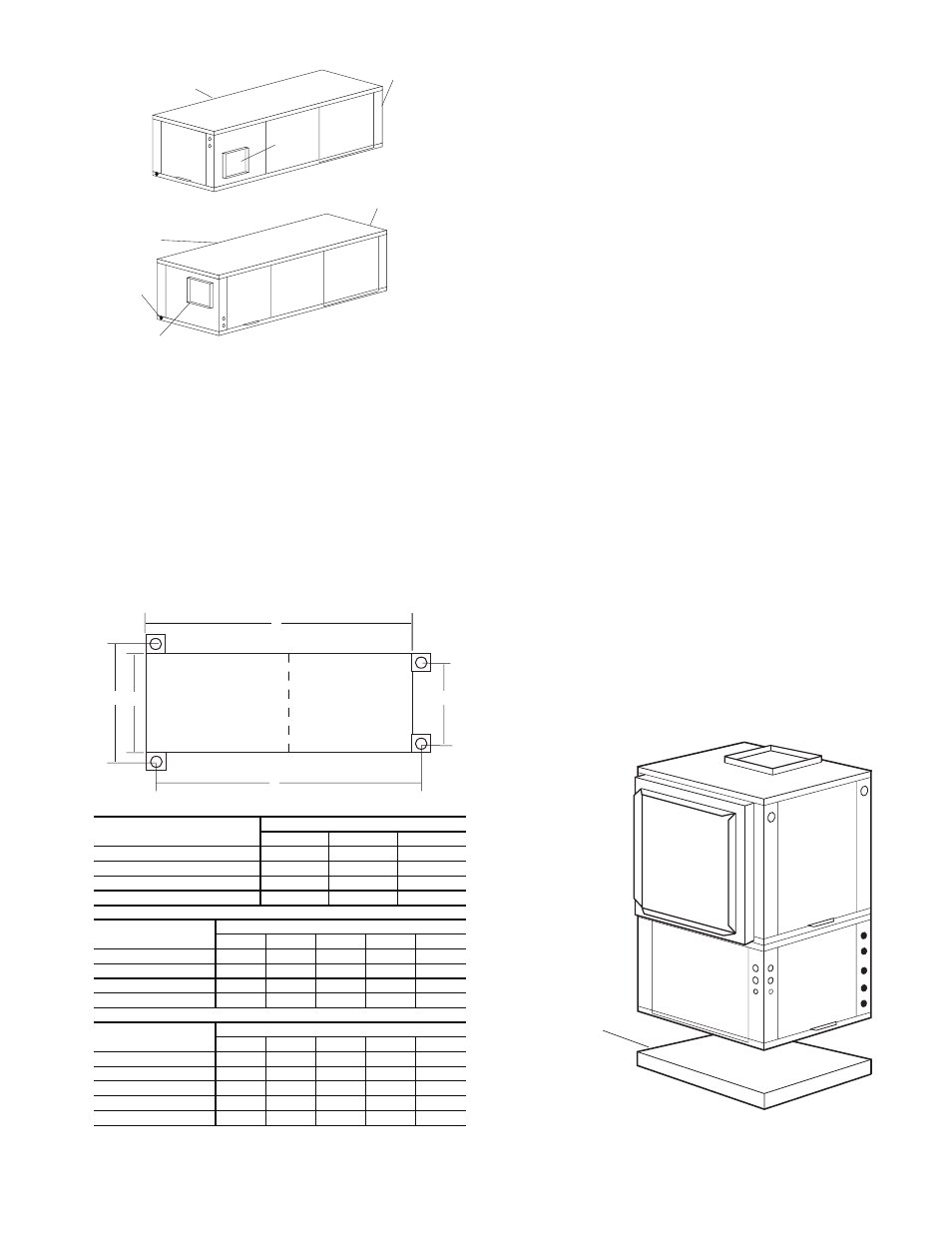

Step 4 — Mounting the Unit

HORIZONTAL UNITS (50RHC,RHR,RHS) — Horizontal units

should be mounted using the factory-installed hangers. Proper

attachment of hanging rods to building structure is critical for

safety. See Fig. 4 and 13. Rod attachments must be able to sup-

port the weight of the unit. See Tables 1-3 for unit operating

weights.

VERTICAL UNITS (50RVC,RVR,RVS,RDS) — Vertical and

downflow units are available in left or right return air configu-

rations. See Fig. 6-8. Mount the unit (except 50RDS) on a

vibration absorption pad slightly larger than the entire base to

minimize vibration transmission. It is not necessary to mount

the unit on the floor. See Fig. 14.

NOTE: Some codes require the use of a secondary drain pan

under vertical units. Check local codes for more information.

Step 5 — Duct System —

Size the duct system to han-

dle the design airflow quietly.

NOTE: Depending on the unit, the fan wheel may have a ship-

ping support installed at the factory. This must be removed

before operating unit.

SOUND ATTENUATION — To eliminate the transfer of

vibration to the duct system, a flexible connector is recom-

mended for both discharge and return air duct connections on

metal duct systems. The supply and return plenums should in-

clude internal duct liner of fiberglass or be made of duct board

construction to maximize sound attenuation of the blower.

Installing the WSHP unit to uninsulated ductwork in an uncon-

ditioned space is not recommended since it will sweat and

adversely affect the unit’s performance.

To reduce air noise, at least one 90-degree elbow could be

included in the supply and return air ducts, provided system

performance is not adversely impacted. The blower speed can

also be changed in the field to reduce air noise or excessive air-

flow, provided system performance is not adversely impacted.

EXISTING DUCT SYSTEM — If the unit is connected to

existing ductwork, consider the following:

• Verify that the existing ducts have the proper capacity to

handle the unit airflow. If the ductwork is too small,

install larger ductwork.

• Check existing ductwork for leaks and repair as

necessary.

NOTE: Local codes may require ventilation air to enter the

space for proper indoor air quality. Hard-duct ventilation may

be required for the ventilating air supply. If hard ducted venti-

lation is not required, be sure that a proper air path is provided

for ventilation air to unit to meet ventilation requirement of the

space.

Water

Connection End

Supply

Duct

Return Air

Water

Connection End

Drain

Return Air

Discharge Air

Side Discharge

Back Discharge

Fig. 12 — Conversion Right Return,

Side Discharge to Back Discharge

Compressor

Section

Air Handler

Section

B

A

C

E

D

D

Fig. 13 — Horizontal Hanger Bracket

(Factory Installed)

50RHC UNITS

DIMENSIONS (in.)

A

B

C

006-012

16.9

34.1

21.1

018-030

18

43.1

22.2

036,042

18

47.1

22.2

048,060

22

54.1

26.2

50RHR UNITS

DIMENSIONS (in.)

A

B

C

D

E

006-024

22.375

43.1

24.375

43.1

20.375

030,036

22.375

52.1

24.375

52.1

20.375

042,048

22.375

61.1

24.375

61.1

20.375

060

25.375

71.1

27.375

71.1

23.375

50RHS UNITS

DIMENSIONS (in.)

A

B

C

D

E

015,018

22.375

51

24.375

53

20.375

024-036

22.375

61

24.375

63

20.375

042,048

25.375

70

27.375

72

20.375

060

25.375

75

27.375

77

23.375

070

25.375

80

27.375

82

23.375

Vibration

Absorption

Pad

Fig. 14 — 50RVC,RVR,RVS Units Mounted With

Vibration Absorption Pad