Pilot and ignition system, Flash carryover, Burner orifices – Reznor BE Unit Installation Manual User Manual

Page 26: Heat exchanger, Fan or blower

Form RZ-NA-I-FE/BE, Mfg P/N 98807 Rev 10, Page 25

Orifice

Compression

Fitting

Pilot

Tubing

Flame Rod

Figure 33 - Pilot

Burner Spark Gap

CAUTION: Due to high voltage on pilot spark wire

and pilot electrode, do not touch when energized.

See Hazard Levels, page 2.

Figure 34 -

Pilot

Assembly

Figure 32 - Pilot Removal

Pilot Hole

Cover Plate

.100

spark

gap

10. To replace the burner rack assembly and the bottom panel,

reverse the above procedure (Steps 1-8).

Individual burners may be cleaned using air pressure. Use an air nozzle

to blow out scale and dust accumulation from the burner ports. Alter-

nately, blow through burner ports and venturi.

CAUTION: Eye protection is recommended.

Use a fine wire to dislodge any stubborn particles. Do not use anything

that might change the port size.

When any service is completed, be careful to reassemble correctly to

ensure that no unsafe conditions are created. When re-lighting, always

follow the lighting instructions on the heater.

34. Pilot and Ignition System

The pilot can be serviced by opening the bottom access panel of the

heater. Follow the first four steps of instructions for Burner Rack

Removal, Paragraph 33. The pilot can be removed to check the wiring,

the spark gap, or to remove the orifice for cleaning. When the pilot is re-

installed, be sure to include the pilot hole cover plate.

Spark gap must be maintained to .100". (See Figure 33.)

In the event the pilot flame is short and/or yellow, check the pilot

orifice for blockage caused by lint or dust accumulation.

Remove the pilot orifice and clean with air pressure. Check and clean

the aeration slot in the pilot burner.

The ignition controller of the intermittent electronic ignition pilot

system is visibly located on the back of the heater. (See Figure 35.) Do

not attempt to disassemble the ignition controller. There are no field

replaceable components in the control enclosure. However, each heat-

ing season the lead wires should be checked for insulation deterioration

and good connections.

Proper operation of the electronic spark ignition system requires

a minimum flame signal of .2 microamps as measured by a

microampmeter.

For further information and check out procedure on the intermittent

electronic ignition pilot system, refer to the manufacturer's control

operating instructions supplied with the heater.

Figure 35

- Ignition

Controller

Location

Ignition

Controller

for Spark

Pilot

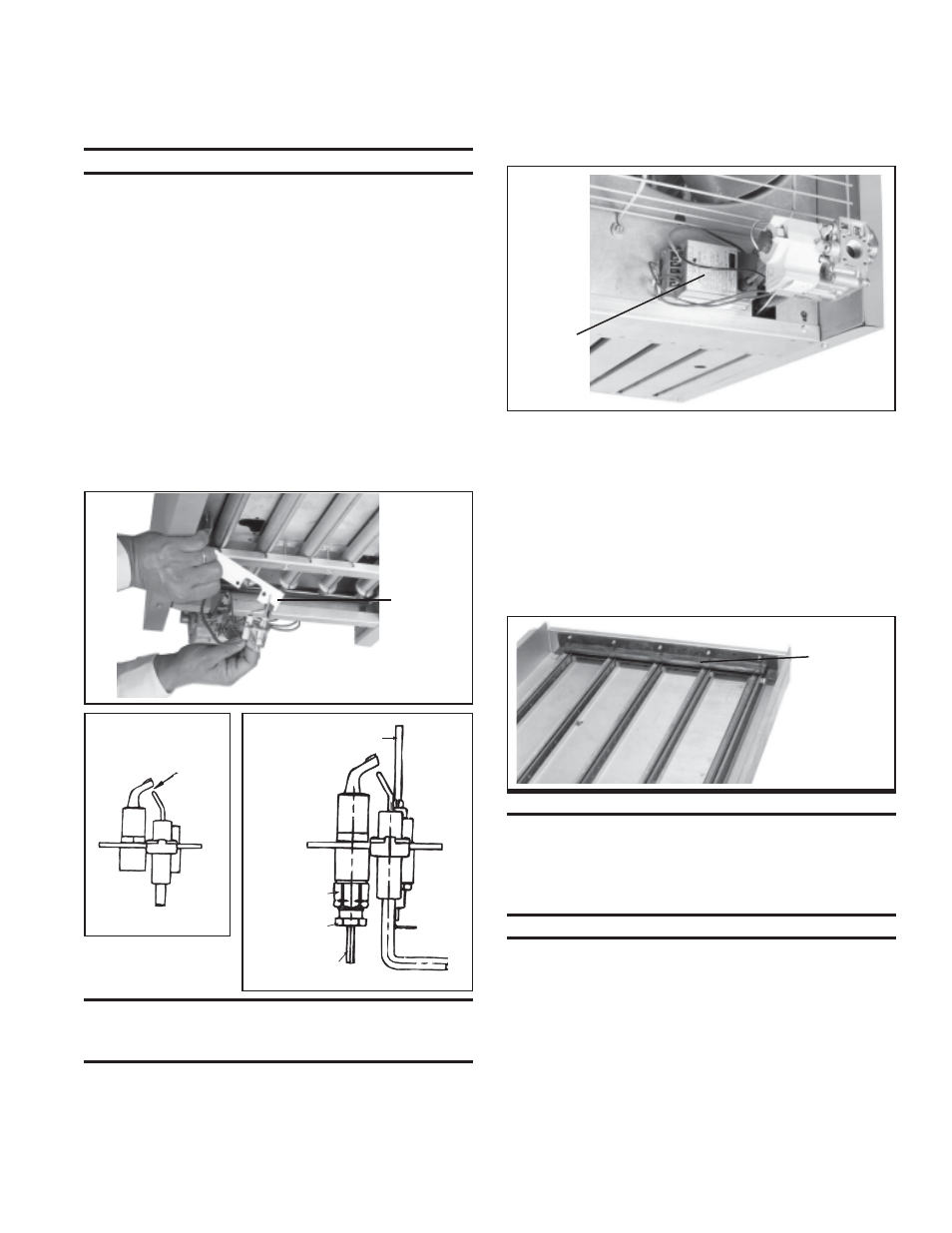

Figure 36 -

Burner

Rack Flash

Carryover

Flash

Carryover

36. Flash Carryover

See Figure 36. The burner carryover system receives its gas supply

from the main burner ports. Check the carryover assembly and also the

main burner ports for cleanliness. Clean with air pressure.

35. Burner Orifices

Heaters are shipped with orifices of proper size and type for gas and

altitude specified on the order. When ordering replacement orifices,

give BTUH content, specific gravity of gas, and altitude, as well as

model and serial number of the heater.

CAUTION: Eye protection is recommended.

37. Heat Exchanger

The outside of the heat exchanger can be cleaned from the front of the

heater with an air hose and/or a brush. Remove all accumulated dust and

grease deposits.

CAUTION: Eye protection is recommended.

The inner surfaces of the heat exchanger can be reached for cleaning

with the burner rack removed. (See Paragraph 33.) Cleaning can be done

with a long furnace brush or a heavy wire to which steel wool has been

attached. Brush up and down inside each heat exchanger tube until all

foreign material is removed. A flashlight is helpful in examining the

upper section of the tube.

38. Fan or Blower

Remove dirt and grease from the motor.

On fan model units, remove dirt and grease from the fan guard and

blades. Use care when cleaning the fan blades to prevent causing mis-

alignment or imbalance. Check that the hub of the fan blades is secure to

the shaft.