Reznor XE Unit Installation Manual User Manual

Page 34

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 33

CAUTION: Water reservoir must be drained

and pump motor turned off when outside

temperature falls below 32°F(0°C). Pump must

never be operated without water in the

reservoir. See Hazard Levels, page 2.

Supply and Drain Water Connections

Float Valve (FIGURE 33) - In a module with pump and float

controls, a float valve maintains the appropriate water level in the

reservoir.

Use a field-supplied 1/4" diameter tubing with a compression nut

and tubing ferrule to connect the fresh water supply to the inlet of

the float valve. See FIGURE 33. Place nut and ferrule over tubing

and insert tubing into the float valve stem. Tighten nut securely.

Simulates

Side Panel

Use 1/4"

Tubing for

Fresh Water

Supply

Compression Nut

and Tubing Ferrule

(Inside

Cabinet)

Float

Valve

Rod

FIGURE 33 -

Connect Fresh

Water Supply to

Inlet of Float

Valve

An optional automatic fill and drain kit (Option CT) is available

that will automatically release supply water to the cooling mod-

ule when a call for cooling is made and drain all water from the

reservoir when the cooling switch is deactivated or a cooling ther-

mostat is satisfied. See FIGURE 34. If installing an optional fill

and drain kit, follow the instructions with FIGURE 34 (right).

Consult wiring diagram for electrical connections.

AquaSaver

TM

Timed Metering Control System - If the cooling

module is equipped with an optional timed metering system, con-

nect a 1/2" water line to the fitting on the side of the cooling

module. Due to various water pressures and installation condi-

tions, the water supply line may bang abruptly when the solenoid

valve in the AquaSaver

TM

system closes. This banging can be

minimized by installing an optional water hammer arrestor in the

supply line. When installing an optional water hammer arrestor,

select an indoor (above 32°F) location, either horizontal or verti-

cal, in line with and as close to the solenoid valve as possible.

Follow the manufacturer's instructions to install and maintain the

water hammer arrestor.

A freeze protection kit (Option CT5) is also available.

All Cooling Modules - A manual water shutoff valve should be

installed upstream of the cooling module inlet, at a convenient

non-freezing location, to allow the water supply to be turned on

and off. If necessary, install a bleed line between the manual valve

and the cooling module to allow drainage of the line between the

shutoff valve and the cooling module.

All cooling modules are equipped with an overflow and drain

fitting. The fittings are in the cabinet bottom and come complete

metering water system, it will not have these controls but will

have a solenoid valve with a timer assembly for controlling water

flow.

Installation Instructions - Evaporative

Cooling Module

The evaporative cooling module is factory assembled, installed

and wired. No additional roof mounting is necessary. Follow these

instructions to field connect the water supply and make neces-

sary checks and adjustments before operating the cooling module.

with a lock nut and a sealing gasket. Check these fittings for tightness before

installing the overflow and drain piping. The drain and overflow fitting will

accommodate a 3/4" garden hose thread and is tapped with a 1/2" female pipe

thread for iron pipe.

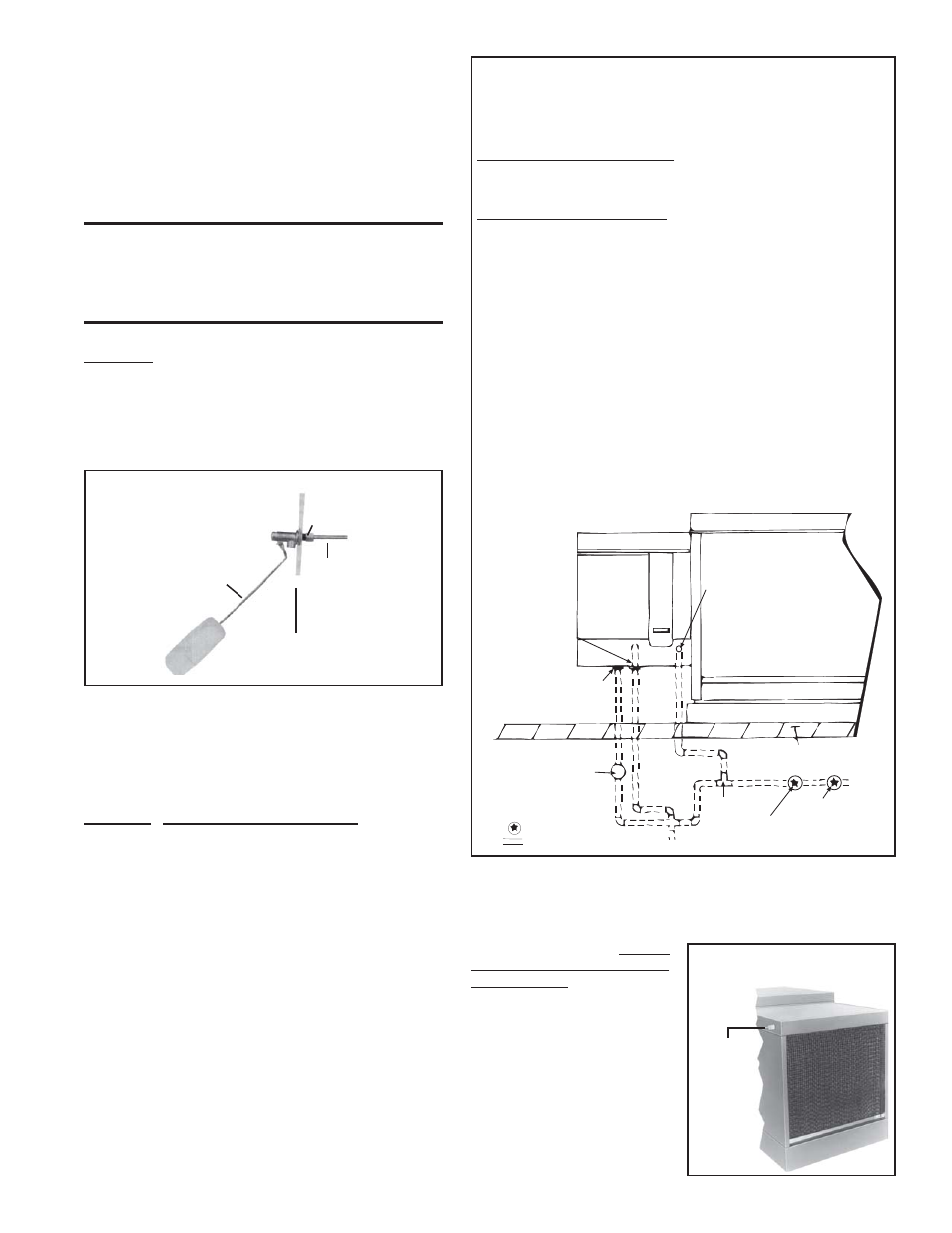

Instructions for Installing Optional Fill & Drain Kit

NOTE: Follow instructions included in the valve packages for attaching

valves to the water line only. The remainder of the installation instruc-

tions with the valves does not apply to this type of application.

Water Line Connections (See illustration below):

Supply (3-Way Valve) Connections - Connect the water supply line to "B"

(normally closed). Connect the water drain line to "A" (normally open).

Connect the middle outlet to supply the water to the cooling module reser-

voir.

Drain (2-Way Valve) Connections - Connect the drain pipe from the reser-

voir to the valve inlet. Connect the outlet side into the drain lines from the

cooling reservoir and the supply valve.

Electrical Connections (requires black and white 14-gauge wire) -

Refer to Wiring Diagram provided with the furnace:

WARNING: Risk of electrical shock. Disconnect the power.

1. Refer to the wiring diagram for terminal connections. (NOTE: If kit is

not ordered with the system, connections will not be shown on the

diagram. Terminal connections are specific to each system. Contact

the factory for terminal connections. Be prepared to provide all model

information.)

2. Run field-supplied black wire from the electrical compartment (terminal

on the wiring diagram) of the evaporative cooling module and connect to

the black wire on both the 3-way and the 2-way valve.

3. Run field-supplied white wire from the electrical compartment (termi-

nal on the wiring diagram) of the evaporative cooling module and con-

nect to the white wire on both the 3-way and the 2-way valve.

Evaporative

Cooling

Module

Float valve inlet water connection

(1/4 compression) or inlet water

connection to solenoid valve

for metering system (1/2 male fitting)

Overflow fitting -

3/4 garden

hose thread tapped

with 1/2 female NPT

Drain fitting - 3/4

garden hose thread

tapped with

1/2 female NPT

2-way solenoid valve

(normally open)

3-way

solenoid

valve

To drain

Pressure regulator

(10 psi max)

Service valve

Roof Line

= Field supplied

= Field-installed water piping

A (N.O.)

B (N.C.)

Water

inlet

FIGURE 34 - Water Connections including Optional Drain and

Fill Kit (pump and float controls)

Bleed Line Connection (Does not

apply to module with optional timed

metering system.) - Shipped in the

evaporative cooling module bottom

pan, find a 1/4" I.D. x 1/2" N.P.T.

nylon bleed line fitting (hose barb).

Thread the fitting into the female

adapter located opposite the pump/

inlet side of the water distribution

line. The hose barb will protrude

from the side of the cabinet (See FIG-

URE 35). Attach a 1/4" I.D. hose to

the barb and run the hose to the near-

est drain.

Install the

hose barb

and attach

bleed line.

FIGURE 35 - Bleed Line Con-

nection