Roof curb assembly and installation – Reznor XE Unit Installation Manual User Manual

Page 10

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 9

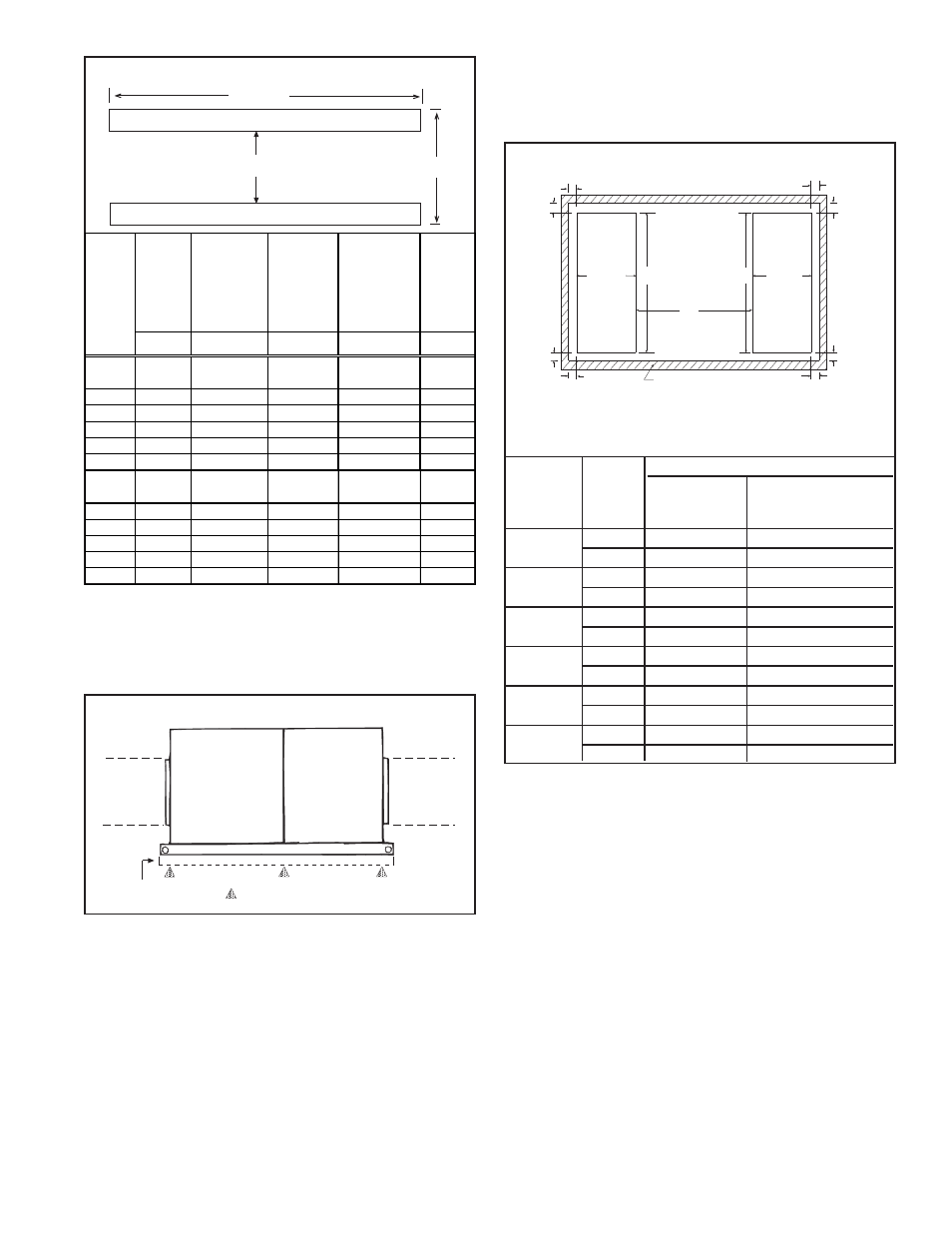

FIGURE 6A - Mounting Support Dimensions (inches/mm)

A

B

4x4 Treated Lumber

Leave both

ends open

for ventilation.

Blower

Cabinet

Furnace

Section

Field

Supplied

Duct

4x4 Treated

Lumber

= Cross Support Locations

Field

Supplied

Duct

FIGURE 6B - Cross-Support Locations

The field-supplied, weather-resistant cross-support structure must be

adequate for the weight of the system (including air conditioning coil if

applicable), and all cross-supports should run the entire width of the

system supporting the 4x4 wooden rails at the recommended locations.

If the treated wooden rails are not being placed directly on the roof

surface, cross-supports should be placed underneath the rails at the

ends of the unit and at all cabinet "joints" (between the blower cabinet

and the furnace section; between the furnace and the optional downturn

plenum or coil cabinet; and between a coil cabinet and a downturn

plenum). See FIGURE 6B.

Mounting on a Roof Curb - Whether using an optional roof curb

available with the system or a field-supplied curb, the curb must be

secure, square and level. The top surface of the roof curb must be

caulked with 1/4" x 1-1/4" sealant tape or two 1/4" beads of suitable

sealant. The unit must be sealed to the curb to prevent water leakage

into the curb area due to wind blown rain and capillary action. Except

for the curb assembly details which are specific to the optional roof

curb available with the system, the information and requirements in

this section apply to all curbs. See FIGURE 8, page 10, and the curb

installation instructions below.

FIGURE 7 - Duct Opening Dimensions in Relation to Roof

Curb Option - inches (mm)

1-5/8

(41)

1-5/8

(41)

1-5/8 (41)

1-5/8 (41)

1-5/8 (41)

1-5/8 (41)

19-1/2

(495)

19-1/2

(495)

H

H

G

Return

Duct

Supply

Duct

Roof Curb

1-5/8

(41)

1-5/8

(41)

•

1-5/8" (41mm) is the measurement from duct opening to

inside edge of roof curb.

•

Duct openings should be 1" larger than the duct size for

installation clearance.

Roof Curb Assembly and Installation Instructions (Refer to

FIGURE 8, page 10)

Curbs are shipped unassembled. Field assembly and mounting on the

roof are the responsibility of the installer. All required hardware neces-

sary to complete the assembly is supplied.

Before installing roof curb, verify that the size is correct for the

system being installed.

1. Position curb cross rails and curb side rails as illustrated in

FIGURE 8, page 10. If there are two side pieces to a side, fasten

them with splice plates and hardware as illustrated in the splicing

detail drawing. Join the corners as illustrated in the corner detail.

2. Check the assembly for squareness. Adjust the roof curb so that

the diagonal measurements are equal within a tolerance of + or -

1/8" (3mm).

3. Level the roof curb. To ensure a good weather tight seal between

the curb cap and the roof curb, the roof curb must be leveled in

both directions with no twist end to end. Shim level as required

and secure curb to roof deck before proceeding with flashing.

4. Install field-supplied flashing.

5. Before placing the unit into position, apply furnished 1/4" x

1-1/4" foam sealant tape to top surface of curb, making good butt

joint at corners. The unit must be sealed to the curb to prevent

water leakage into the curb area due to blown rain and capillary

action.

Model

G

Series

H

With Downturn

w/Cooling Coil Cabinet

CRGB and

Plenum, Option

w/Downturn, Options

RPB Sizes

AQ5 or AQ8

AU 11, 12, 13, or 14

75, 100,

17-3/8"

38-5/8"

75-31/32"

125

441mm

981mm

1930mm

150, 175

22-7/8

38-5/8

81-15/32

581mm

981mm

2069mm

200, 225

28-3/8

38-5/8

86-31/32

721mm

981mm

2209mm

250, 300

36-5/8

38-5/8

95-1/4

930mm

981mm

2419mm

350

42-1/8

38-5/8

100-3/4

1070mm

981mm

2559mm

400

47-5/8

38-5/8

106-1/4

1210mm

981mm

2699mm

Bottom Duct Connections - The blower section and optional down-

turn plenum have duct flanges for connection to return air and supply

air ducts. Duct opening sizes and curb spacing shown in FIGURE 7 is

for currently manufactured curbs that are available from the system

manufacturer.

Standard

He ate r

and

Blowe r

Package

Wi th Factory-

Instal l e d

Downturn

Pl e num

Cabi ne t

(O ption AQ )

W i th

Shippe d-

Se parate

C ool ing

C oil

C abi ne t

(O pti on AU)

Wi th Shi ppe d-

Se parate

C ool i ng C oi l

C abi ne t wi th

Downturn

Ple num

(O pti on AU)

A

ll

Co

nfi

g

ur

a

ti

o

ns

"A"

"A"

"A"

"A"

"B"

75, 100,

125

60-5/8"

84-9/16"

98-3/8"

122-1/4"

24-5/16"

150, 175

60-5/8"

84-9/16"

103-7/8"

127-7/8"

29-13/16"

200, 225

60-5/8"

84-9/16"

109-3/8"

133-3/8"

35-5/16"

250, 300

60-5/8"

84-9/16"

117-5/8"

141-5/8"

43-9/16"

350

60-5/8"

84-9/16"

123-1/8"

147-1/8"

49-1/16"

400

60-5/8"

84-9/16"

128-5/8"

152-5/8"

54-1/2"

75, 100,

125

1540mm

2148mm

2499mm

3105mm

618mm

150, 175

1540mm

2148mm

2638mm

3248mm

757mm

200, 225

1540mm

2148mm

2778mm

3388mm

897mm

250, 300

1540mm

2148mm

2988mm

3597mm

1106mm

350

1540mm

2148mm

3127mm

3737mm

1246mm

400

1540mm

2148mm

3267mm

3877mm

1384mm

M

o

del Series

CRGB

a

nd RP

B Sizes