Direct digital control system, Pilot and ignition systems, Optional electronic modulation (cont'd) – Reznor XE Unit Installation Manual User Manual

Page 29: Or bacnet

Form I-XE/CRGB/RPB, Page 28

Measure manifold

pressure

during burner cycling.

When the

manifold pressure is

BELOW 1.0" w.c., is there a steady

voltage between Terminal 95

and Terminal 7?

Replace secondary

manifold pressure

switch.

While the

burner is cycling, is

there a steady voltage

between Terminal 84 and

Terminal 2?

Replace the

primary manifold

pressure switch.

When the

manifold pressure is

ABOVE 1.5" w.c., is there a steady

voltage between Terminal 95

and Terminal 7?

Replace secondary

manifold pressure

switch.

Is there voltage

between Terminal 4 of the

ignition premissive relay and

Terminal 7?

Replace ignition

permissive

relay.

YES

NO

YES

NO

YES

NO

Is there 24 volts

between Terminal 2 on #1

Time Delay Relay and

Terminal 7?

Go to

Troubleshooting

Chart for heater.

Is there 24 volts

between Terminal 84 and

Terminal 7?

Is the

damper open?

Is there voltage

between Terminal 88 and

Terminal 7?

Is there voltage

between Terminal 4 on

ignition permissive relay and

Terminal 7?

Replace #1 time

delay relay.

Replace ignition

permissive

relay.

Check combustion

damper lower end switch

adjustment. If necessary,

replace end switch.

Is there voltage

between Terminal 87 and

Terminal 7?

Check combustion

damper lower end switch

adjustment. Replace end

switch if necessary.

Place a jumper

across Terminal

86 and Terminal 7.

Did the

damper close?

Replace motor

run time delay

relay.

Replace combustion

damper gear motor.

Replace primary

manifold

pressure switch.

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

YES

NO

26. Direct Digital Control System -

Model Series CRGB and RPB

The heater is equipped with a specially programmed Johnson Controls

Metasys

®

direct digital control unit. The unit is mounted in the blower

cabinet; see FIGURE 26. If interfacing with the building's Johnson Con-

trols Building Automaton System, follow the instructions included in

the owner's envelope. The control unit has two analog outputs, six

analog inputs, six binary outputs, and four binary inputs.

25C. and 25D. Electronic

Modulation between 20% -

28% and 100% Firing Rate

(cont'd)

25. Optional Electronic Modulation (cont'd)

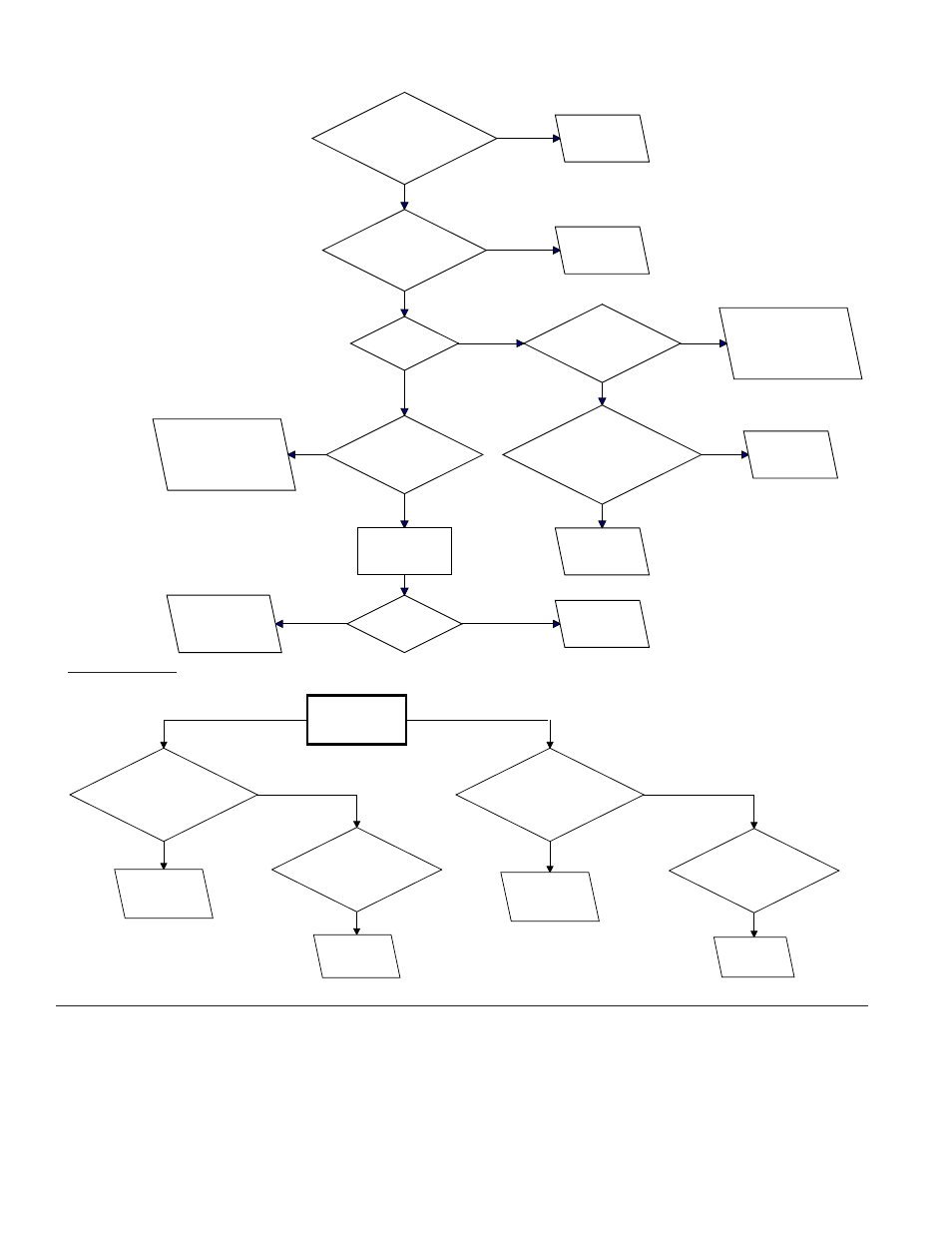

Troubleshooting Guide for

Checking Bypass

Combustion Air Damper

Safety Circuit on Model

RPB with Option AG39 or

AG40

General Instructions: For each step,

check to ensure that the wiring is not

defective and that the wiring connec-

tions are secure.

Symptom: Main burners are inopera-

tive. Assumes that 24 volts is available

between Terminal 2 and Terminal 7.

Symptom - Part 2:

Steady call for heat - burner cycles. Assumes that 24 volts is available between Terminals 11 and 7 and Terminals 2 and 7.

(NOTE: With the addition of a field-supplied integrator, the controller

can also be used with a Honeywell or Siebe building management sys-

tem or with any Lonworks

TM

or BacNet

TM

based protocol system.)

The unit can also operate the system as a stand alone control at the

default settings.

Depending on which option was ordered, the following functions are

available for monitoring and control through the building's environmen-

tal system. Option D1 has modulating dampers and modulating gas