Condenser startup form – Reznor MASA Unit Installation Manual User Manual

Page 38

Form I-COND, P/N 220746R6, Page 38

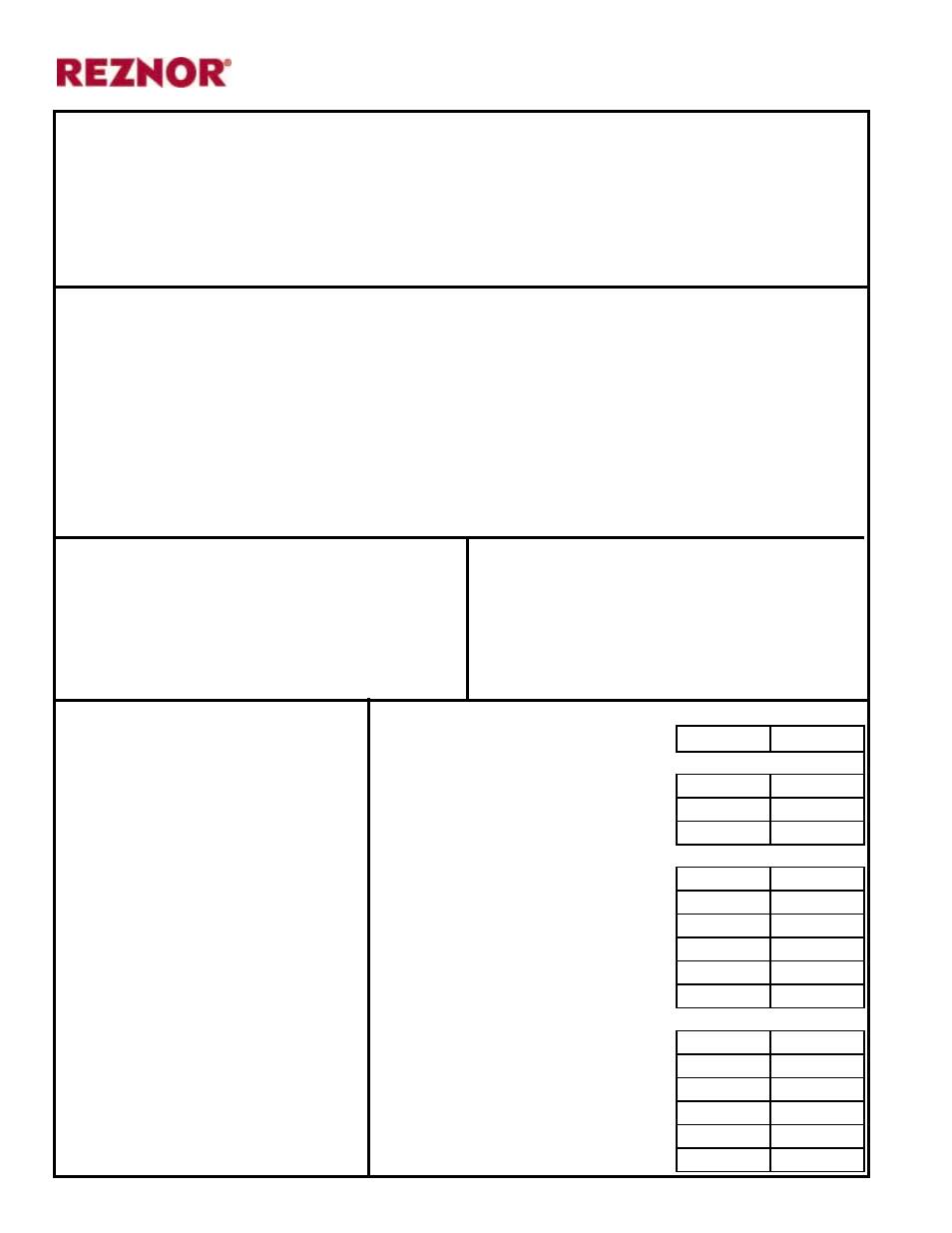

Customer Name: _______________________________ Condenser Model #: _______________________

Address: _____________________________________ Condenser Serial #: _______________________

City, State Zip: ________________________________ Air Handler Brand: ________________________

Contractor Firm Name: __________________________ Air Handler Model #: _______________________

Installing Contractor: ____________________________ Air Handler Serial #: _______________________

□

Remove all shipping supports and restraints (Section 3.0)

□

Check unit for damage (Section 3.0)

□

Check air flow clearances (Section 9.1.1)

□

Verify incoming power matches unit rating (Section 9.1.1)

□

Check & tighten all electrical connections (Section 9.1.1)

□

Check unit for proper field installed wiring (Section 9.1.1)

□

Check free rotation of condenser fan(s) (Section 9.1.1)

□

Crankcase heater ON for 24 hours (Section 9.2)

□

Check manual high pressure reset switch (Section 8.3.1)

□

Leak tested field-installed refrigerant lines (Section 6.2.2)

□

Check refrigerant line free from rubbing

□

Filter driers installed (Section 6.1.3.3)

□

Trap installed (if required) (Section 6.1.3.4)

□

System evacuated to 500 microns (Section 6.3)

□

Proper start-up of air handling equipment (Section 9.1)

□

Condenser A connected to evaporator A (B to B) (Section

6.1)

□

Thermostatic expansion valves properly installed (Sec-

tion 6.1.3.3)

CONDENSER STARTUP FORM

Complete on initial startup. Completed form may be required for warranty.

PRE-STARTUP CHECK LIST (

See Section References for details.)

ELECTRICAL CHECKS

PIPING CHECK

Date: __________

OPERATIONAL DATA

Operate for 30 minutes for system to stabilize

Circuit A

Circuit B

Subcooling Temperature

Liquid line temperature leaving condenser

°F(°C) °F(°C)

Liquid line pressure leaving condenser

psig

psig

Subcooling temperature

°F(°C) °F(°C)

Superheat Temperature

Suction line temperature leaving evaporator

°F(°C) °F(°C)

Suction line temperature entering condenser °F(°C) °F(°C)

Suction line pressure entering condenser

psig

psig

Superheat temperature

°F(°C) °F(°C)

Optional hot gas bypass start to open

lbs.

lbs.

Optional hot gas bypass full open

lbs.

lbs.

Test Conditions

Condenser fan entering air temperature

°F(°C) °F(°C)

Condenser fan leaving air temperature

°F(°C) °F(°C)

Evaporator entering dry bulb air temperature °F(°C) °F(°C)

Evaporator entering wet bulb air temperature °F(°C) °F(°C)

Evaporator leaving wet bulb air temperature

°F(°C) °F(°C)

Evaporator leaving dry bulb air temperature

°F(°C) °F(°C)

Refrigerant line length:

Circuit A

Circuit B

____ Liquid

____ Liquid

____ Suction ____ Suction

Hot gas bypass installed: ____ Circuit A ____ Circuit B

Leak tested PSIG:

____ Circuit A ____ Circuit B

Hold time: ____ Circuit A ____ Circuit B

Total lbs of R-410A added: ____ Circuit A ____ Circuit B

Breaker & fuses rating:

_____V

_____A

Voltage imbalance:

_____%

Compressor running forward _____Y

_____N

Outdoor Air Temperature:

_____°F(°C)

Compressor Amperage

_____Circuit A _____Circuit B

NOTES: