Caution – Reznor MASA Unit Installation Manual User Manual

Page 31

Form I-COND, P/N 220746R6, Page 31

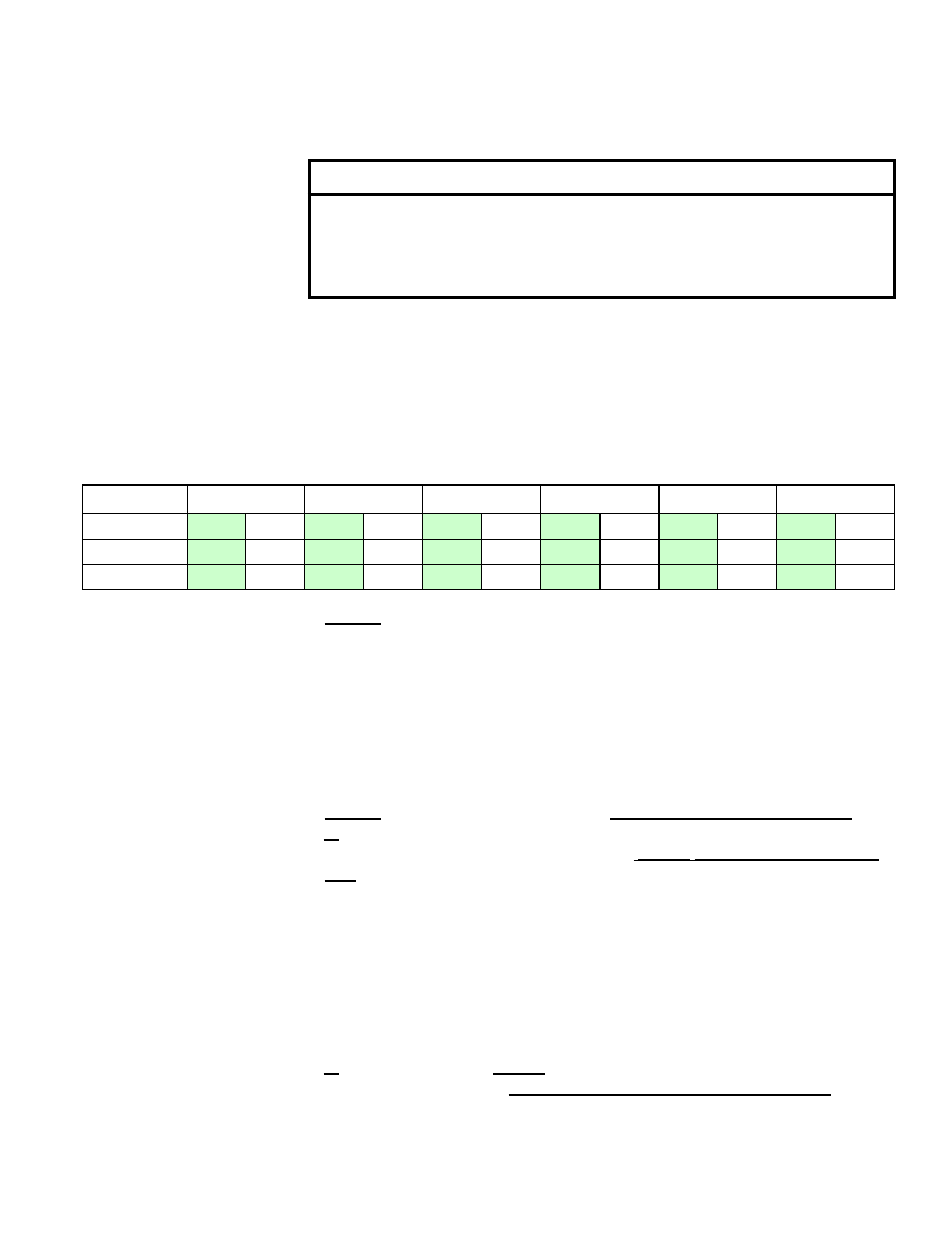

TABLE 10 -

Compressor Oil

Charge

MASA Size

060

090

120

150

180

240

Circuit

A

B

A

B

A

B

A

B

A

B

A

B

Compressor

ZP20K

ZP39K

ZP29K

ZP57K

ZP39K

ZP83K

ZP54K

ZP103K

ZP57K

ZP120K

ZP83K

ZP154K

POE Oil (oz.)

34

38

21

52

38

56

62

106

52

106

56

106

□

Step 3. Mount the Replacement Compressor

Do not remove the dust cover or rubber shipping plugs until all other sys-

tem connections are complete (i.e. new liquid line filter drier(s) installed

and all tubing changes made - see Steps 4 and 5). The amount of time the

compressor is open to the atmosphere must be kept to a minimum.

Use the new mounting grommets and sleeves that are shipped with the

compressor to mount it. The sleeves will prevent over compression of

the grommets. Re-use the mounting bolts from the compressor that was

removed. The mounting bolts will bottom out when tight.

□

Step 4. Install New Filter Driers (Select procedure that applies.)

IF the oil measured in Step 2 was not significantly less than the amount

shown in TABLE 10 or the test for acid in

Step 2 did NOT indicate burn-

out , install a new R-410A refrigerant liquid line filter drier. The filter drier

must be rated for no less than 600 psig and be the proper size for the

circuit. Because R-410A refrigerant requires POE oil which absorbs mois-

ture quickly, it is important to change the filter drier any time the circuit is

opened.

It is recommended to use a tubing cutter when cutting out a filter drier as

the desiccant absorbs and holds moisture better when it is cool. Heat from

a torch may cause moisture to leave the filter and be absorbed in the oil.

Continue to

Step 5.

IF the oil measured in Step 2 was significantly less than shown in TABLE

10 or the test for acid in

Step 2 did indicate compressor burnout, do the

following:

a) Install a liquid line filter drier.

If there is acid, install an acid removing

filter drier. Size the acid-removing filter drier at least one capacity size

larger than normally required for the circuit.

d) Remove the mounting bolts and the compressor. Save the mounting

hardware to attach the grommets and sleeves shipped with the replace-

ment compressor.

e) To test for acid and to assure excess oil does not remain in the circuit,

remove oil from the failed compressor. Measure the amount of oil.

CAUTION

In addition to the required eye protection and gloves, care

should be taken in handling POE oil because it may cause

damage to certain plastics and roofing materials. See Hazard

Levels, page 3.

If the oil taken from the compressor and measured is found to be signifi-

cantly lower than listed in

TABLE 10, clean the excess oil through use

of suction and liquid line filter driers.

Beginning in Step 4, follow the

same procedure as for burnout cleanup.

Use an acid test kit to check the oil for acid.

If acid is found, begin-

ning in Step 4, follow procedures indicated for burnout cleanup.

Dispose of oil and compressor using an approved environmentally safe

disposal method.