0 mechanical (cont’d), 1 refrigerant piping (cont’d) – Reznor MASA Unit Installation Manual User Manual

Page 12

Form I-COND, P/N 220746R6, Page 12

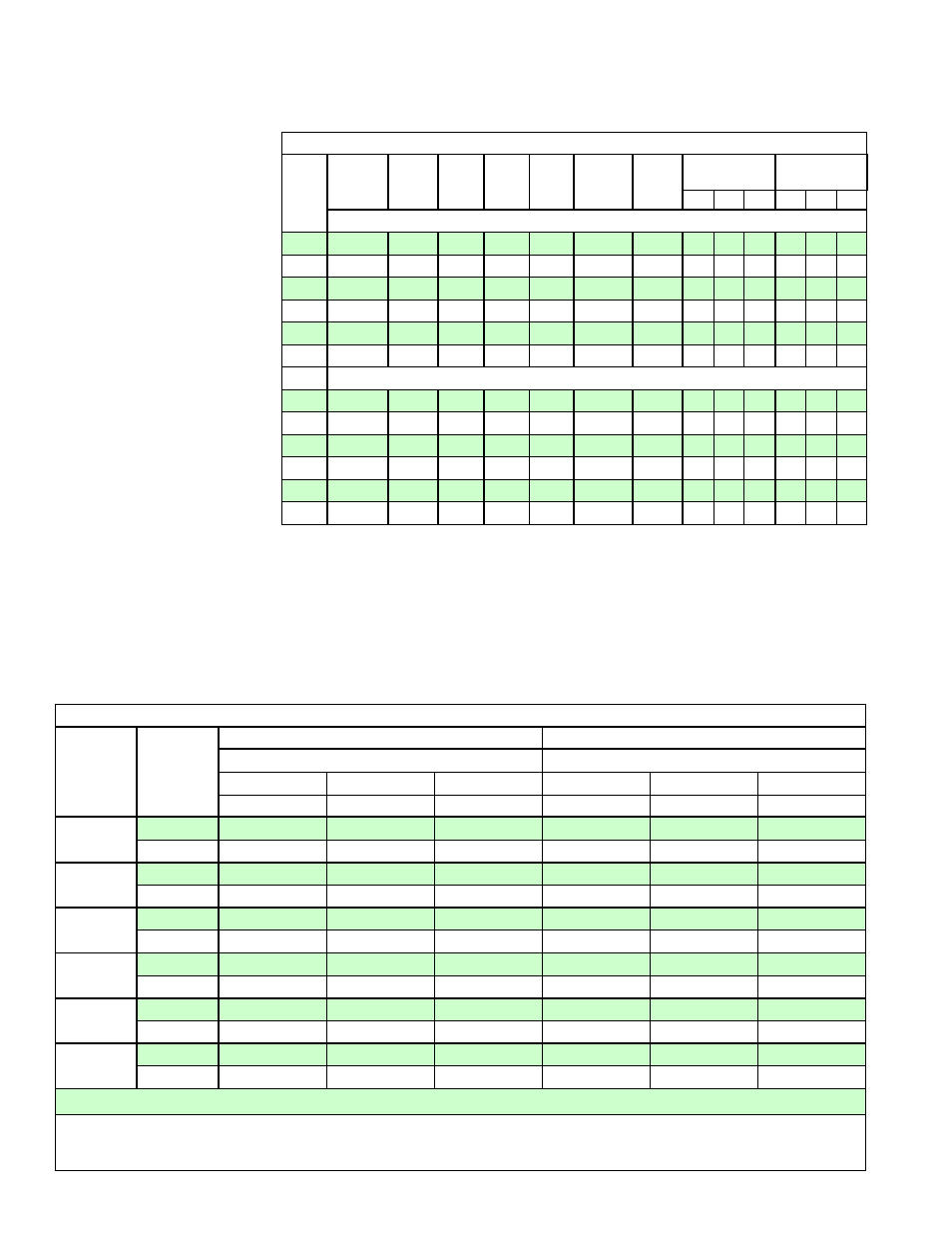

TABLE 3 -

Recommended Size

of Refrigerant Piping

for each Segment

determined by the

Equivalent Length

Use the worksheet on page 13, and the information in

TABLE 2 and TABLE 3

to determine the line segment and circuit equivalent lengths and the size

of tubing required for each line segment.

IF AN APPLICATION REQUIRES MORE THAN 60 FEET (18.3M) OF EQUIV-

ALENT LENGTH OF TUBING (LIQUID LINE OR SUCTION LINE) BETWEEN

THE CONDENSER AND THE AIR HANDLER, CONTACT REZNOR FOR

APPROVAL.

TABLE 2 - Fitting

Pressure Loss in

Equivalent Length

of Straight Copper

Tubing

Equivalent Length of Fittings and Accessories

Line

Size

OD

Globe /

Solenoid

Valve

Angle /

Check

Valve

90º SR

Elbow

90º LR

Elbow

45º

Elbow

Tee Line

/ Sight

Glass

Tee

Branch

Coupling to

Enlarge OD by

Coupling to

Reduce OD by

1/

4"

1/

2"

3/

4"

1/

4"

1/

2"

3/

4"

Equivalent Length (in Feet of Pipe)

1/2"

9

5

1.4

0.9

0.4

0.6

2.0

1.

4

0.

8

0.

3

0.

7

0.

5

0.

3

5/8"

12

6

1.5

1.0

0.5

0.8

2.5

1.

8

1.

1

0.

4

0.

8

0.

7

0.

4

3/4"

14

7

1.9

1.3

0.6

0.9

3.0

2.

5

1.

5

0.

5

1.

2

1.

0

0.

5

7/8"

15

8

2.3

1.5

0.7

1.0

3.5

3.

2

2.

0

0.

7

1.

6

1.

2

0.

7

1-1/8"

22

12

2.7

1.8

0.9

1.5

4.5

4.

7

3.

0

1.

0

2.

3

1.

8

1.

0

1-3/8"

28

15

3.6

2.4

1.2

1.8

6.0

5.

8

3.

6

2.

9

2.

9

2.

2

1.

2

Equivalent Length (in Meters of Pipe)

1/2"

2.7

1.5

0.4

0.3

0.1

0.2

0.6

0.

4

0.

2

0.

1

0.

2

0.

2

0.

1

5/8"

3.7

1.8

0.5

0.3

0.2

0.2

0.8

0.

6

0.

3

0.

1

0.

2

0.

2

0.

1

3/4"

4.3

2.1

0.6

0.4

0.2

0.3

0.9

0.

8

0.

5

0.

2

0.

4

0.

3

0.

2

7/8"

4.6

2.4

0.7

0.5

0.2

0.3

1.1

1.

0

0.

6

0.

2

0.

5

0.

4

0.

2

1-1/8"

6.7

3.7

0.8

0.6

0.3

0.5

1.4

1.

4

0.

9

0.

3

0.

7

0.

6

0.

3

1-3/8"

8.5

4.6

1.1

0.7

0.4

0.6

1.8

1.

8

1.

1

0.

9

0.

9

0.

7

0.

4

6.0 Mechanical

(cont’d)

NOTE: Liquid line filter

driers provided have 1/2”

connections. Add equil-

valent length for filter

driers plus, if liquid line is

not 1/2”, add equilvalent

for fittings.

*Minimum Recommended Refrigerant Piping Size

MASA

Model

Circuit

Suction Line Tubing Size (OD)

Liquid Line Tubing Size (OD)

**Equivalent Length of the Suction Line - Ft (M)

**Equivalent Length of the Liquid Line - Ft (M)

Up to 25 Ft

> 25 to 50 Ft

> 50 to 60 Ft

Up to 25 Ft

> 25 to 50 Ft

> 50 to 60 Ft

(Up to 7.6M)

(> 7.6 to 15.2M)

(> 15.2 to 18.3M)

(Up to 7.6M)

(> 7.6 to 15.2M)

(> 15.2 to 18.3M)

60

A

1/2

5/8

3/4

1/2

1/2

1/2

B

3/4

3/4

7/8

1/2

1/2

1/2

90

A

5/8

3/4

3/4

1/2

1/2

1/2

B

7/8

7/8

1 1/8

1/2

1/2

1/2

120

A

3/4

3/4

7/8

1/2

1/2

1/2

B

7/8

1 1/8

1 1/8

1/2

5/8

5/8

150

A

7/8

7/8

1 1/8

1/2

1/2

1/2

B

1 1/8

1 1/8

1 3/8

1/2

5/8

5/8

180

A

7/8

7/8

1 1/8

1/2

1/2

1/2

B

1 1/8

1 1/8

1 3/8

1/2

5/8

5/8

240

A

7/8

1 1/8

1 1/8

1/2

5/8

5/8

B

1 1/8

1 3/8

1 3/8

5/8

3/4

3/4

*Based on copper tubing type L; a 2°F loss; and a maximum of 65ºF suction line (return gas) temperature and liquid line temperature of 105ºF.

**Equivalent Line Segment Length = length of field-installed tubing in line segment plus equivalent length of all field-installed fittings and

accessories in line segment. For both liquid line and suction line segments, maximum recommended equivalent length is 60 ft (18.3M).

CAUTION: Maximum equivalent length of a hot gas bypass line is 30 ft (9.1M).

6.1 Refrigerant Piping (cont’d)

6.1.3 Refrigerant Piping Guidelines (R-410A Refrigerant) (cont’d)

6.1.3.2 Refrigerant Piping Length and Size (cont’d)