2 leak test the refrigerant circuits, 1 leak test the condensing unit, Caution – Reznor MASA Unit Installation Manual User Manual

Page 16

Form I-COND, P/N 220746R6, Page 16

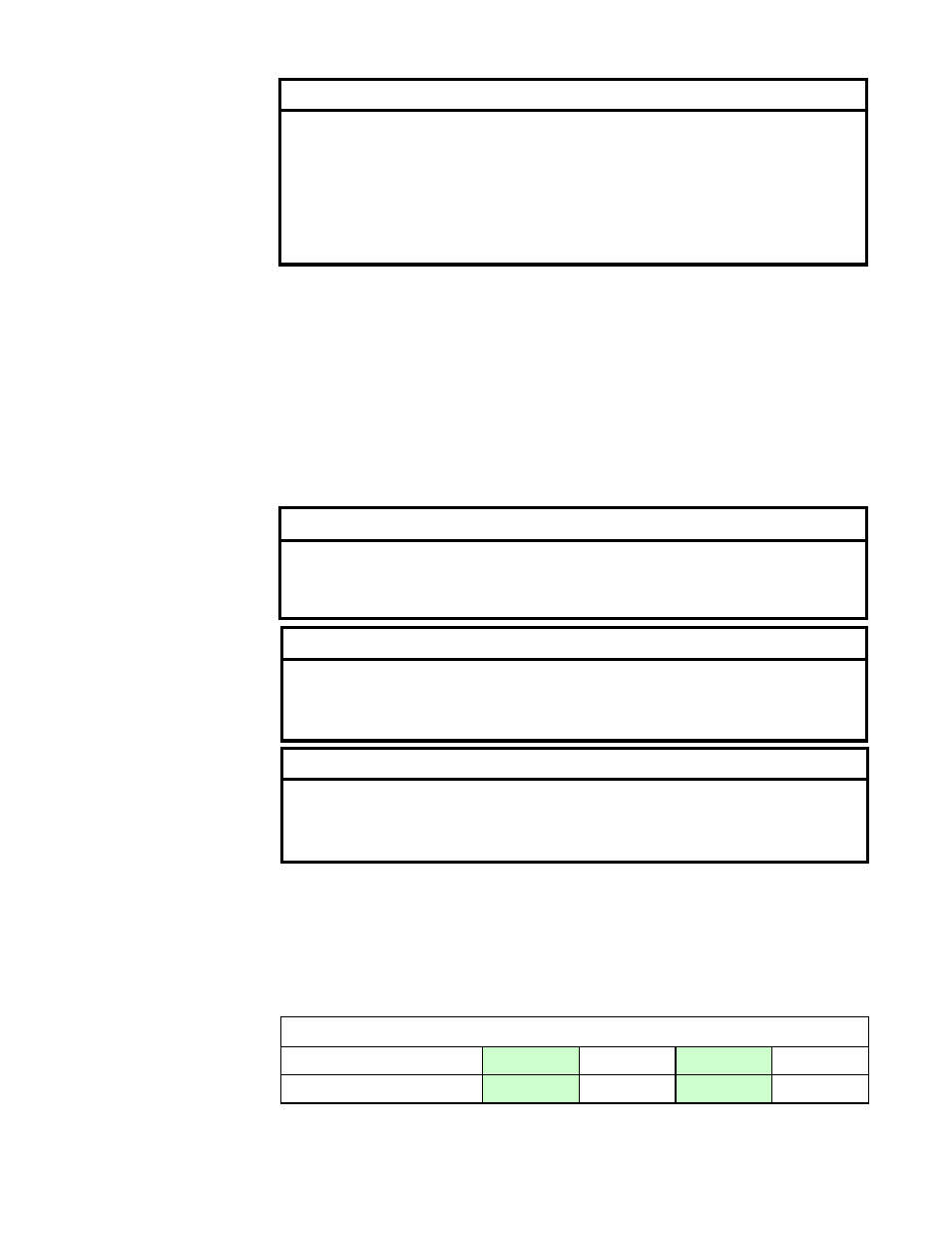

Maximum Spacing Between Pipe Supports for Copper Tubing

Nominal Diameter (OD)

5/8"

7/8"

1-1/8"

1-3/8"

Maximum Span

5 ft (1.5M)

6 ft (1.8M)

7 ft (2.1M)

8 ft (2.4M)

TABLE 5 - Maximum

Spacing between

Pipe Supports

6.0 Mechanical

(cont’d)

6.1.3.6 Brazing Connections

CAUTION

Do not leave system open to the atmosphere any longer

than minimum required for installation.

Exposure for more

than five minutes may contaminate the system.

POE oil in the

compressors is extremely susceptible to moisture absorption.

Always keep ends of tubing sealed during installation. See

Hazard Levels, page 3.

Brazing materials must be able to withstand the high pressure of R-410A refrig-

erant. A high temperature, silver phosphate type brazing with 5% or greater

alloy is recommended.

To prevent oxidation, purge tubing with 2-3 psig of regulated dry nitrogen while

it is being brazed. Before brazing connections, check the condenser unit for

leaks (See Paragraph 6.2.1). After the unit has been properly leak tested, the

nitrogen remaining in the circuit can be used as part of the purge while braz-

ing. Open the service valve as needed to release the nitrogen.

Do not allow

moisture to enter the system.

The installer is responsible for brazing and for complying with appropriate stan-

dard refrigerant piping procedures.

CAUTION

All brazing should be done using a 2 to 3 psig dry nitrogen

purge flowing through the pipe being brazed. See Hazard

Levels, page 3.

CAUTION

Do not open the service valves until after the condenser unit

circuits are leak tested (See Paragraph 6.2.1.) See Hazard

Levels, page 3.

CAUTION

When brazing, protect all painted surfaces and components

from excessive heat. Wet wrap all valves but do not allow

moisture to enter the tubing. See Hazard Levels, page 3.

6.2 Leak Test the

Refrigerant

Circuits

6.1.3.7 Piping Support and Insulation

Comply with piping support spacing requirements in

TABLE 5.

Insulate the entire length of each suction line and optional hot gas bypass

line(s). Insulate any portion of the liquid line that is subject to extreme tempera-

ture. To prevent vibration noise, isolate all piping from the building structure or

ductwork.

6.2.1 Leak Test the Condensing Unit

The condensing unit is shipped with a 50 psi nitrogen holding charge in each

circuit. Install gauges to assure that the condensing unit sections of Circuit A are

6.1 Refrigerant

Piping (cont’d)

6.1.3 Refrigerant

Piping Guidelines

(R-410A Refrigerant)

(cont’d)