3 liquid line piping – Reznor MASA Unit Installation Manual User Manual

Page 13

Form I-COND, P/N 220746R6, Page 13

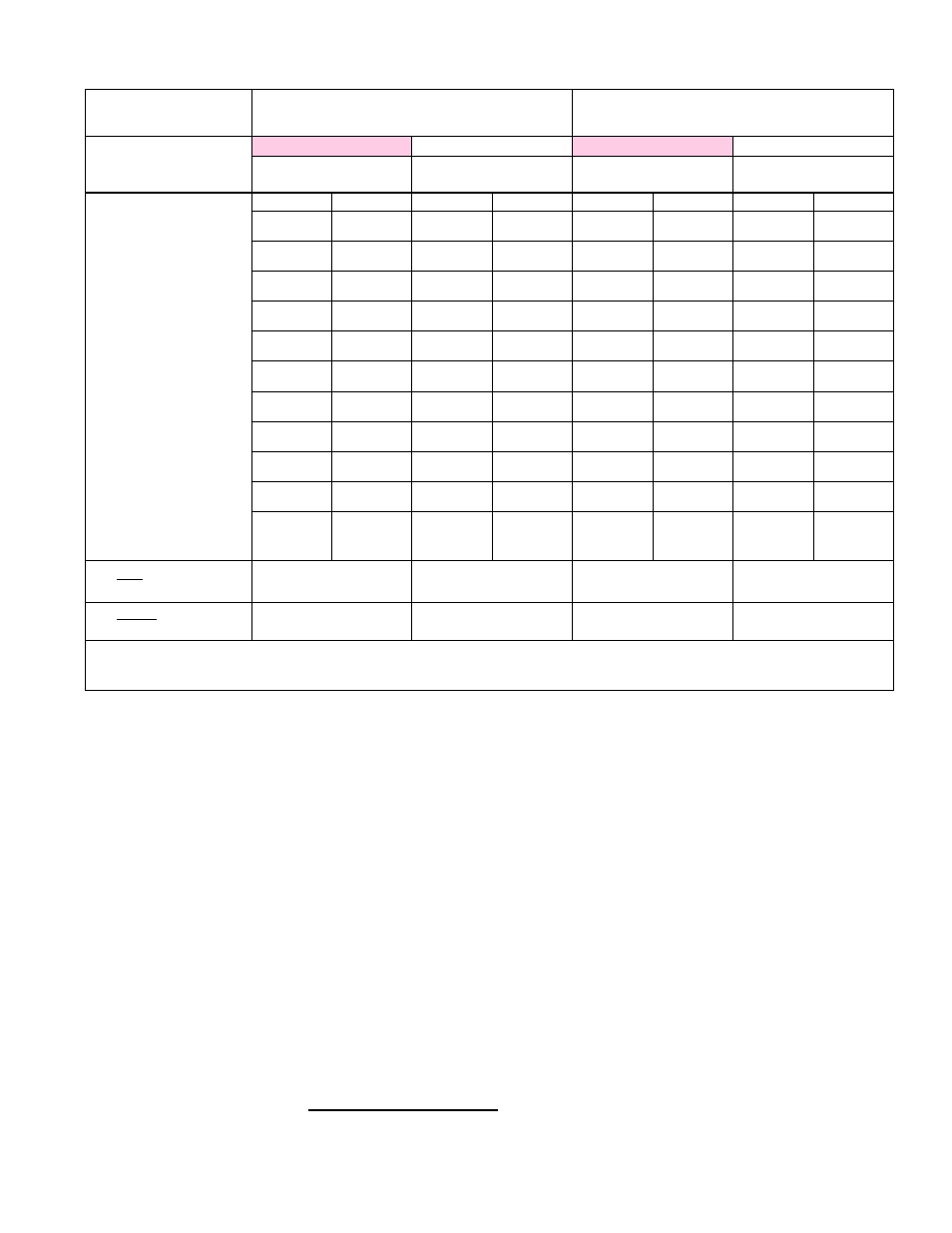

Circuit (field-installed Liquid

Line Segment and Suction

Line Segment)

CIRCUIT A (1/3 Circuit)

CIRCUIT B (2/3 Circuit)

Line Segment (field-

installed refrigerant tubing)

Liquid Line

Suction Line

Liquid Line

Suction Line

Tubing Size ________

Tubing Size ________

Tubing Size ________

Tubing Size ________

Equivalent Lengths of All

Accessories and Fittings in

the Line Segment

Component

Length

Component

Length

Component

Length

Component

Length

Subtotal of

Equivalent Lenghts of

Accessories/Fittings

Plus Actual Length of Line

Segment

Equals Equivalent Line

Segment Length

IMPORTANT Note: Recommended maximum total equivalent standard line length between the condenser and evaporator coil is 60ft

(18.3M). For line segments longer than 60ft (18.3M) equivalent length, consult Reznor for approval. CAUTION: Maximum total equivalent

length of a hot gas bypass line is 30 ft (9.1M).

WorkSHEET for calculating the equivalent length of each of the four line segments.

6.1.3.3 Liquid Line

Piping

Design the liquid lines (a line for each circuit from the condenser to the ther-

mostatic expansion valve on the appropriate distributor at the evaporator coil)

so that the pressure drop in the liquid refrigerant will not be greater than that

corresponding to an approximate 1 to 2°F of subcooling. Pressure loss of 5

psi results in a 1°F loss of subcooling temperature with R-410A refrigerant.

The total loss is the pressure drop loss through the piping and fittings plus any

additional for lift or accessories (shutoff valve, filter, etc). Pressure loss due to

lift is approximately 0.5 PSI per foot.

Each liquid line requires field installation of one of the filter driers supplied

with the unit (see instructions below and

FIGURE 4A or 4B). Filter driers are

sized for each circuit; see

TABLE 4 to match the filter drier with the circuit.

Also, it is highly recommended that each liquid line include a field-supplied

solenoid valve and a sight glass with a moisture indicator. (NOTE: Do not rely

on the sight glass for determining amount of refrigerant charge; see Paragraph

6.4 and subcooling and superheat checks in Paragraph 9.2.3 for determining

refrigerant charge. A sight glass with a moisture indicator is important because

moisture is very detrimental to an R-410A refrigerant circuit.) Install the recom-

mended field-supplied sight glass with moisture indicator downstream of the

filter drier and upstream of the thermostatic expansion valve.

Liquid Line Filter Driers - Two liquid line filter driers are shipped loose for field

installation. Match the filter drier to Circuit A or Circuit B as listed in

TABLE 4.

Follow the filter drier manufacturer’s instructions and install the correct filter

drier in each liquid line close to the condensing unit. The arrow on the drier