Reznor MASA Unit Installation Manual User Manual

Page 15

Form I-COND, P/N 220746R6, Page 15

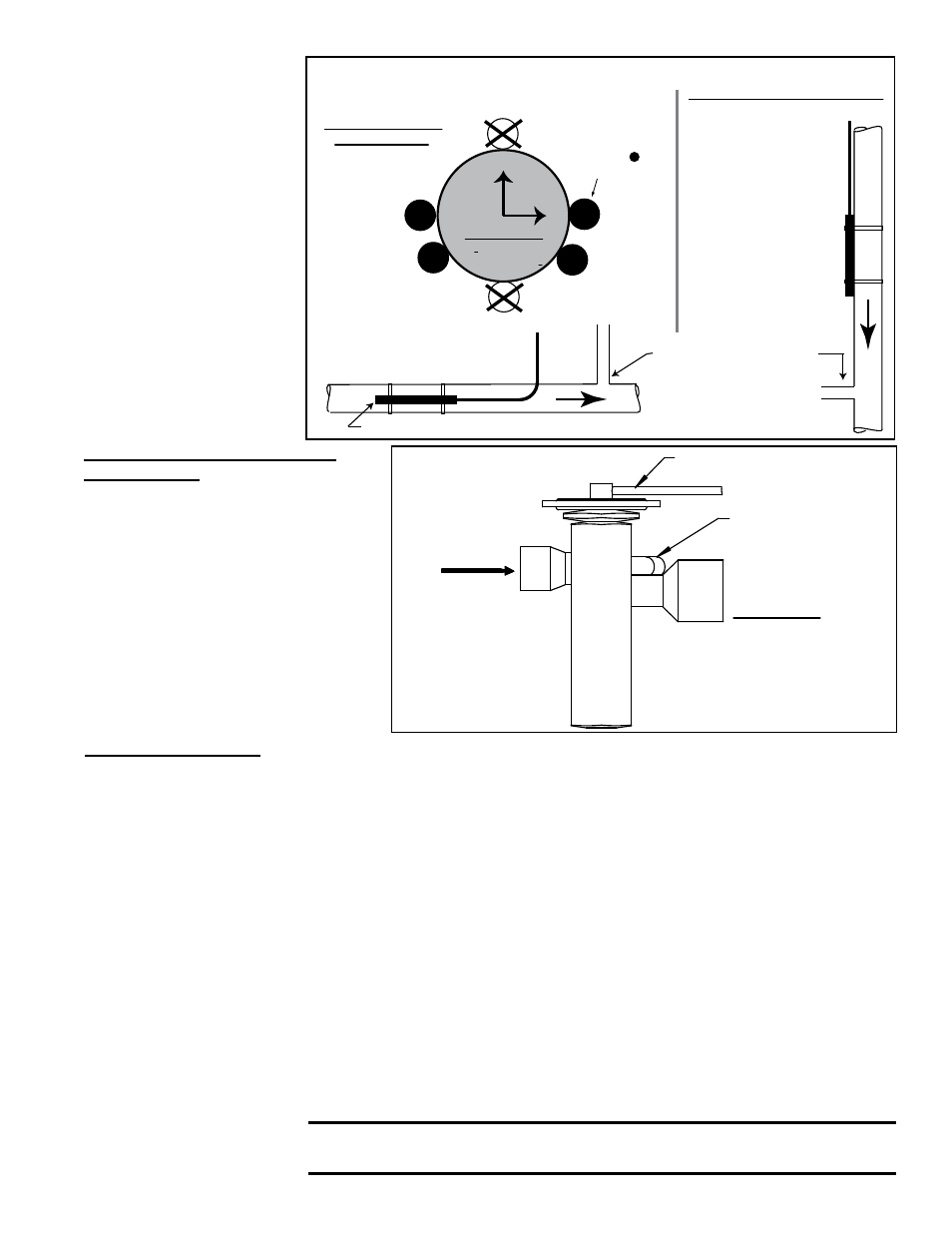

3 o’clock

4 o’clock

8 o’clock

9 o’clock

12

3

6

9

Position bulb flat against the surface of the suction line tubing. Secure bulb

tightly and insulate.

Suction Line

(Enclarged

Cross Section)

Suction Line

Thermostatic Expansion Valve (TXV) Bulb

Suction Line

Thermostatic

Expansion

Valve (TXV) Bulb

(Capillary tube should

be out the top.)

Horizontal Section

of Suction Line

(preferred location)

Vertical Section of Suction Line

(descending flow only)

Capillary

tubing

from TXV

Capillary tubing from TXV

Connect field-supplied

equalizer tubing from the TXV

(FIGURE 5B) into the

suction line a short

distance downstream

of the bulb.

Locate bulb at

one of the

positions.

FIGURE 5A - Suction

Line showing

orientation and

location of the

Thermostatic

Expansion Valve

Bulb and the

Equalizer Tubing

6.1.3.4 Suction Line

Suction Line Piping

- The suction lines (lines carrying refrigerant vapor from the evaporator to the com-

pressor) should be designed to provide minimum pressure drop and to return oil to the compressor under all

load conditions. A suction line is normally sized to have a pressure drop no greater than an approximate 2°F

of superheat.

Design and installation of the suction lines are critical to efficient operation and compressor life. Suction lines

must be insulated and pitched in direction of flow. To ensure oil return, refrigerant velocity in vertical lines

should be at least 1500 ft/minute and at least 750 ft/min in horizontal lines.

If the evaporator coil is above the condensing unit, a trap is required in the suction line as it leaves the evapo-

rator. The top of the trap must be higher than the top of the evaporator. A trap is not required and should not

be used when the condensing unit is above the evaporator.

Isolate the liquid lines from the suction lines. Insulate the entire length of each suction line.

6.1.3.5 Optional Hot

Gas Bypass Lines

Tubing for the optional hot gas bypass is field-supplied and installed. See the

illustration in

FIGURE 4A or 4B, page 9 or 10. Refer to FIGURE 3, page 6,

for location of condenser unit connection(s) and Paragraph 6.1.3.6 for braz-

ing requirements. Connect the other end of the hot gas bypass line(s) into the

corresponding circuit liquid line between the thermostatic expansion valve and

the distributor on the evaporator coil using a field-supplied auxiliary side con-

nector.

CAUTION: The maximum equivalent length of a hot gas bypass

line is 30 feet (9.1M).

Thermostatic Expansion Valve

Equalizer Line - The Model MASA

condensing unit requires thermostatic

expansion valves with an external

equalizer. To ensure that the correct

pressure is signaled to the valve,

an external equalizer line must be

connected into the

suction line

immediately

downstream of the

thermostatic expansion valve bulb

(See

FIGURE 5A).

Attach the other end of the equalizer

line to the stem on the thermostatic

expansion valve (

FIGURE 5B).

FIGURE 5B -

Thermostatic

Expansion Valve

Equalizer Line

30” (762mm) Capillary Tube

to Bulb (See FIGURE 5A)

1/4” ODF External

Equalizer Fitting

requires field-supplied

tubing connected into

the suction line just

downstream of the

TXV bulb.

Thermostatic

Expansion

Valve (TXV)

INLET

NOTE: A PreevA

®

evaporator coil ordered

with hot gas bypass has

a factory-installed side

connector for attaching

the hot gas bypass line.