2 leak test the field-installed piping – Reznor MASA Unit Installation Manual User Manual

Page 17

Form I-COND, P/N 220746R6, Page 17

pressurized. If circuit is not pressurized, the nitrogen has escaped. Recharge

with dry nitrogen to 150 psi. (Maximum test pressure is 450 psi.) Use soap

bubbles or other leak-detecting method. Repair as needed to ensure a leak-

free circuit in the condensing unit. Repeat with Circuit B.

NOTE: The nitrogen charge in the condensing unit circuits may be used during

the brazing process as part of the purge. See Paragraph 6.1.3.6.

6.2.2 Leak Test the

Field-Installed Piping

Pressurize one of the circuits with dry nitrogen to 150 psi. (Maximum test pres-

sure is 450 psi.) Test for leaks. Repair as needed to ensure a leak-free circuit.

When the circuit is successfully leak tested, allow the nitrogen to escape to the

atmosphere through the pump port on the gauge manifold. Repeat with the

second circuit.

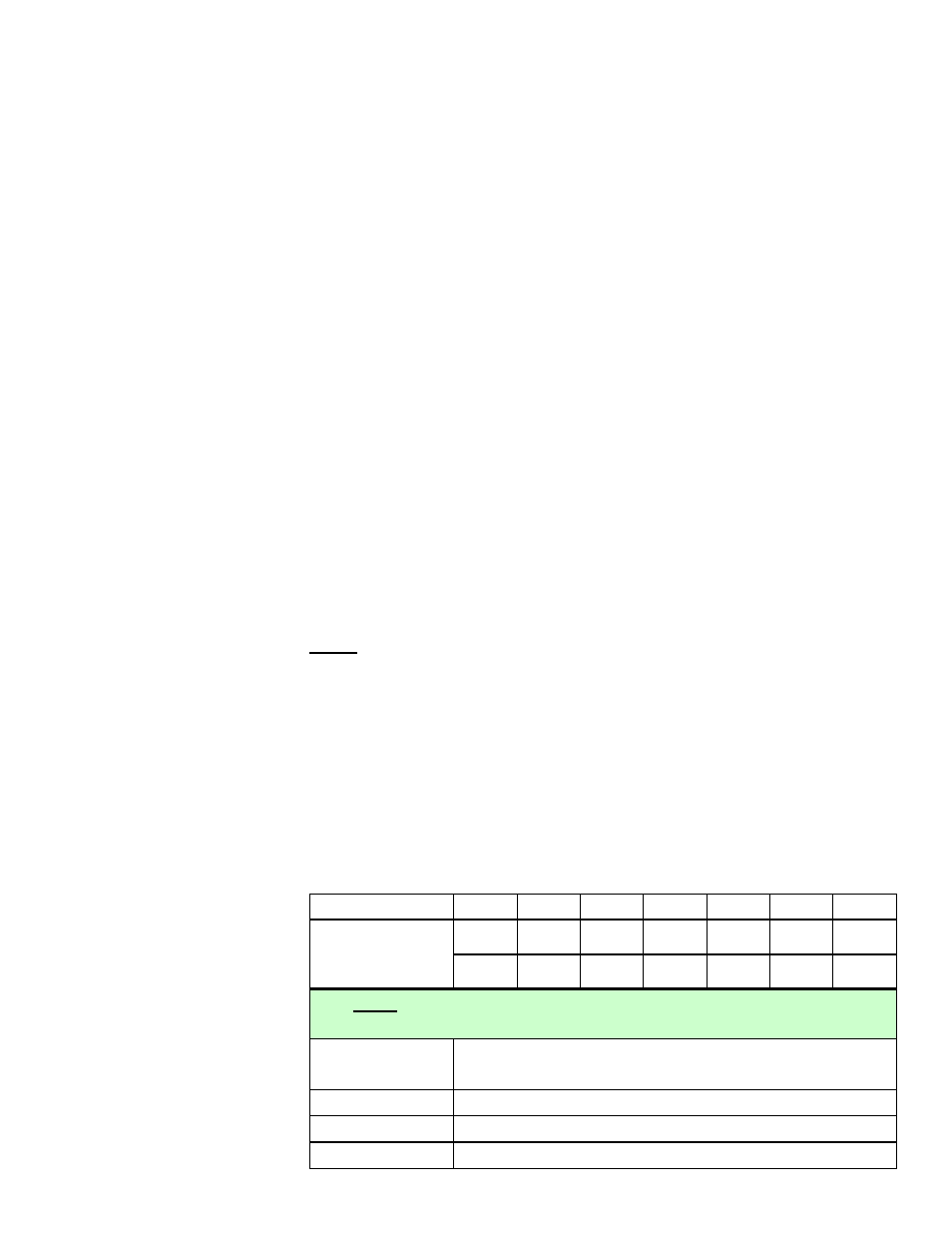

TABLE 6 - Condenser

Refrigerant Charge

by Weight and Line

Charge per Size and

Length of Liquid Line

MASA Size

Circuit

60

90

120

150

180

240

Condenser

Refrigerant

Charge (lbs)

A

5.0

6.0

6.3

9.6

8.6

11.0

B

5.9

9.0

9.5

11.2

11.3

14.8

PLUS lbs listed below of R-410A refrigerant per each 50 feet (15.2M)

actual length of liquid line by tubing size

Liquid Line

Tubing Size (OD)

Lbs of R-410A Refrigerant (saturated liquid @

77°F/25°C) per each 50 ft (15.2M) of Liquid Line

1/2

3.4

5/8

5.4

3/4

8.0

6.3 Evacuate the

Circuits

Evacuate one circuit at a time. Use a vacuum pump and micron gauge. Each

circuit must be evacuated to hold a 500 micron vacuum. Vacuum must be

pulled on both the discharge (high) and suction (low) side. Do the suction

side first; and the compressor discharge side second. To establish that a cir-

cuit is leak-free and moisture-free, a standing vacuum test is recommended.

Close off the valve to the vacuum pump and observe the micron gauge. If the

vacuum gauge does not rise above 500 microns in one minute, the evacua-

tion should be complete. If vacuum gauge does rise above 500 microns in one

minute, evacuation is incomplete or the system has a leak. Repeat as needed

until evacuation is complete. The evacuation process must be done on each

circuit.

NOTE: Evacuation will not remove moisture from POE oil. Moisture must be

prevented from getting in the oil.

6.4 Charge with R-

410A Refrigerant

Use only R-410A refrigerant.

NOTE: Outdoor temperature must be between 70-95°F (21-35°C) for verifying

superheat and subcooling. If temperature is not within this range, consult the

factory service department before charging.

If equipped with an optional hot gas bypass, disable the hot gas bypass valve

before charging. Remove cap and backoff spring tension until valve is dis-

abled. (

NOTE: See Paragraph 8.3.3 to reset.)

Estimate the refrigerant charge for each circuit.

TABLE 6 lists the weight of

refrigerant required for each condenser (condenser coil and receiver) plus the

amount per foot depending on size and length of the liquid line.

Charge the refrigerant slowly through the gauge port on the liquid line.

R-410A refrigerant must be charged as a liquid. R-410A cylinders are rose

colored (pink) and have a dip tube for charging liquid from an upright position.