Notice, Warning – Proheat M80 User Manual

Page 45

o)

Connect the Power, Overheat/Temperature Sensor and Coolant Pump

electrical connections to the heater Burner Had and reconnect the fuel line.

p)

Activate the heater with the remote switch and observe operation. The

heater should run smoothly with no smoke although there may be some

hesitation initially due to air in the fuel line.

q)

Remove the remote switch and re-connect the control connection.

If a Start diagnostic code is indicated, proceed to Step 7.

Test Procedure – Air Compressor pressure (Rotary Vane Compressor models):

h)

Thread in Pressure Gauge Adapter hand tight as shown in Figure 4-16.

i)

Install pressure Relief Valve & Pressure Gauge on to Pressure Gauge Adapter.

j)

Orient Burner Head similar to assembled on heater.

k)

Connect Power Harness and Remote Switch to the G-I PCM.

l)

Switch the PROHEAT on and observe the air pressure:

PROHEAT G-I PCM SERVICE MANUAL

4-14

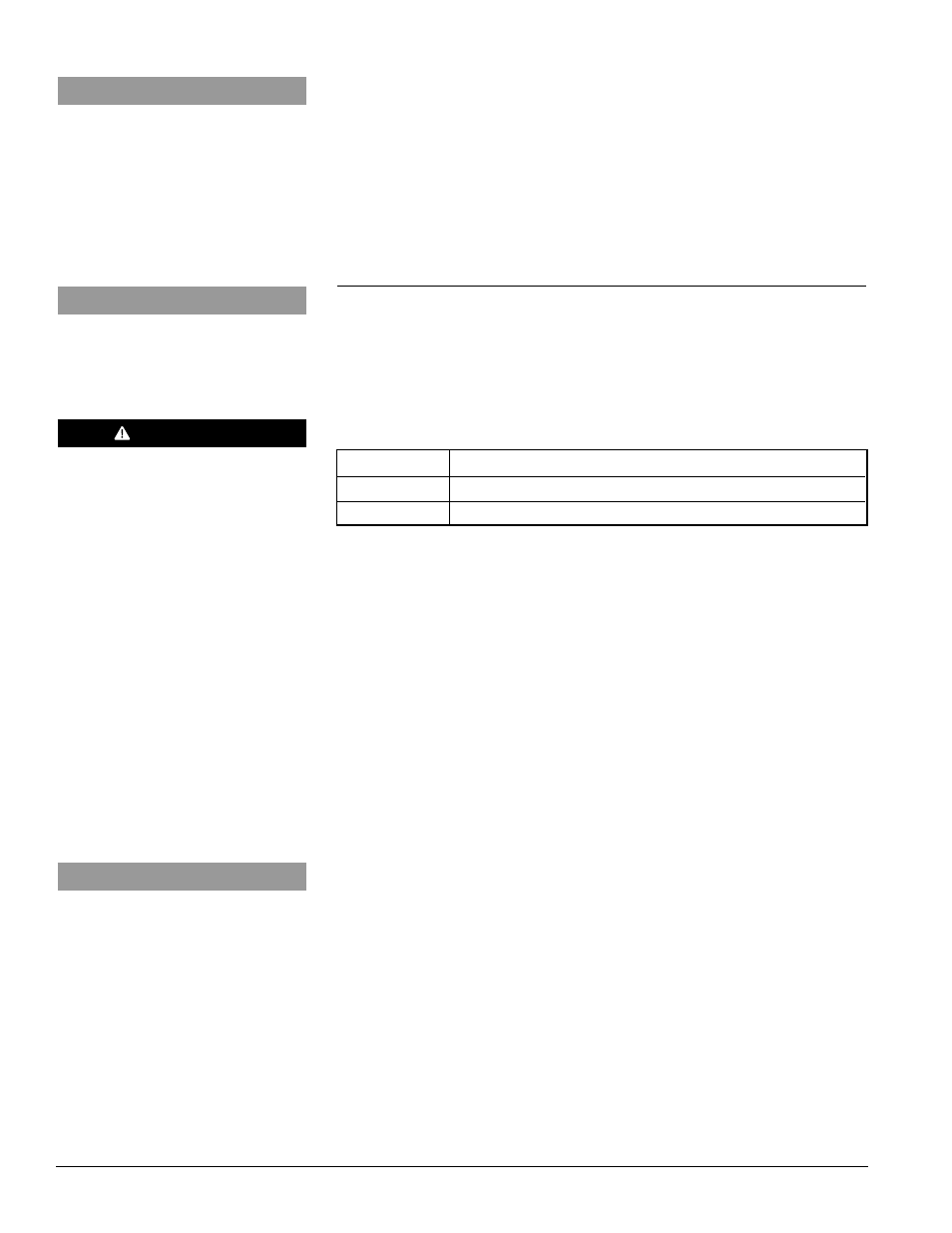

MODEL

AIR PRESSURE (ROTARY VANE COMPRESSOR)

M50

6.2 ± 0.1 PSI (42.7 ± 0.7 kPa)

M80

3.2 ± 0.1 PSI (22.1 ± 0.7 kPa)

NOTICE

Ensure to orient burner head as shown

in Figure 4-16 or an incorrect pressure

measurement may be made.

NOTICE

All plugs/harnesses must be rein-

stalled into the Proheat Control

Module (G-I PCM) before heater goes

back into service.

NOTICE

All plugs/harnesses must be rein-

stalled into the Proheat Control

Module (G-I PCM) before heater goes

back into service.

WARNING

Connect power and switch only. DO

NOT connect the temperature sensor.

m) Adjust the air pressure if necessary by releasing the lock nut and turning

the pressure relief cap as shown in Figure 4-17.

If the pressure cannot be set to the correct setting, read Section 5.2.

Rotary Vane Compressor Service and Vanes Installation to check

operation. If required, replace rotary vane compressor as shown on

page 4-15.

n)

Tighten the lock nut to 50 in-lbs ±5 in-lbs (5.6 Nm ±0.6) and ensure the

air pressure did not change after tightening the lock nut.

o)

Turn the heater off. Wait until purge mode is complete (approx. 3 minutes).

p)

Remove the Pressure Gauge Adapter and Harness. Lubricate Air Pressure

Relief Valve O-ring with diesel fuel and re-install the Air Pressure Relief

Valve in it’s original location. Torque to 25 in-lbs ±3 in-lbs (2.8 Nm ±0.3

Nm). Reconnect the Ignition Module and Fuel Solenoid connector to the

G-I PCM. Re-install the Flame Shield, the Ignition Electrode Assembly and

Burner Head onto the Heat Exchanger.

q)

Connect the Power, Overheat/Temperature Sensor & Coolant Pump

electrical connections to the heater Burner Head and reconnect the fuel

line.

r)

Activate the heater with the remote switch and observe operation. The

heater should run smoothly with no smoke although there may be some

hesitation initially due to air in the fuel line.

s)

Remove the remote switch and re-connect the control connection.

If a Start diagnostic code is indicated, proceed to Step 7.