Great Planes Edge 540 1.60-43cc Performance Series ARF - GPMA1414 User Manual

Page 34

34

them with the slots for the rudder cables. Mark the location

for the screw holes. Drill through the marks you made with

a 3/32" [2.4mm] drill bit.

Be sure you are drilling through

the plate only! Do not drill all the way through the rudder.

Using a #4 x 5/8" [16mm] self-tapping screw, install and then

remove a screw into each of the holes. Harden the holes with

thin CA. Install the control horns with eight #4 x 5/8" [16mm]

self-tapping screws.

CLEVIS

RETAINER

CLEVIS

SWAGE

CABLE

THREADED

COUPLER

4-40

NUT

o

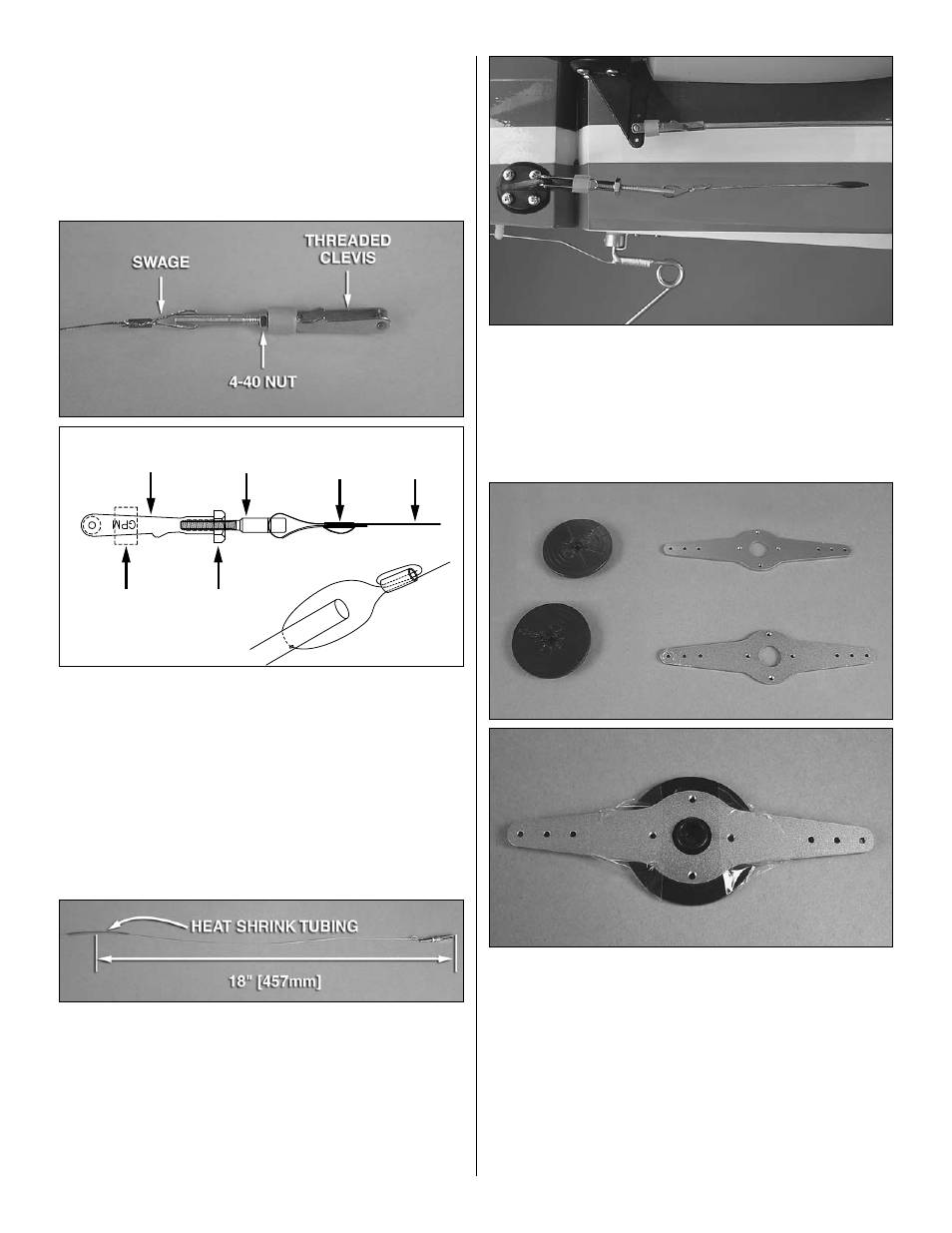

4. Cut the provided pull-pull cable into two equal lengths.

Thread on a 4-40 nut and a silicone clevis retainer onto

each of the four brass pull-pull couplers and then thread the

couplers into four 4-40 metal clevises twelve complete turns.

Feed only one end of each cable through the hole in a brass

coupler 1-1/4" [32mm] and fold it back onto itself. Slide a

swage onto the cable and over the short end, loop the short

end around through the swage again and crimp the swage

onto the cables using heavy-duty pliers. The other ends

of the cables will be connected to the clevises after being

installed into the fuselage.

o

5. Slide a 3" [76mm] piece of 1/16" [1.6mm] heat-shrink

tubing onto each pull-pull cable. Use heat to shrink the

tubing onto the cable. Slide the heat-shrink tubing down the

cable so that the center of the tubing is 18" [457mm] from

the

clevis pin. Apply a drop of medium CA glue to both ends

of each piece of tubing to secure it in place. The heat shrink

tubing will prevent the metal cables from directly contacting

each other where

they cross inside the fuselage which

could cause radio interference.

o

6. Feed the pull-pull cables through the slots in the

fuselage. Be sure that the other ends make it through the

fuselage to the rudder servos and do not interfere with the

elevator servo leads. Turning the airplane up on its nose and

feeding the cable ends into the fuse makes this task easier.

Connect the clevises on the cables to the outer holes in the

rudder control horns.

o

7. Two 3-7/8" [98mm]

double aluminum servo arm

extensions are included for the rudder pull-pull system.

Locate the large servo wheels included with the rudder

servos. (Different model servos may come with servo wheels

that are larger or smaller than the ones shown in the picture.

The actual size of the servo wheels being used is not critical.)

Fit the aluminum servo extensions to the undersides of the

servo wheels centered over the spline holes and tape them

in place. Use a 1/16" [1.6mm] drill bit to drill through the four

mounting holes in the servo extensions into the plastic servo

wheels. Remove the servo wheels from the extensions and

enlarge the holes with a 3/32" [2.4mm] drill bit.