Install the throttle servo (glow) – Great Planes Edge 540 1.60-43cc Performance Series ARF - GPMA1414 User Manual

Page 21

21

o

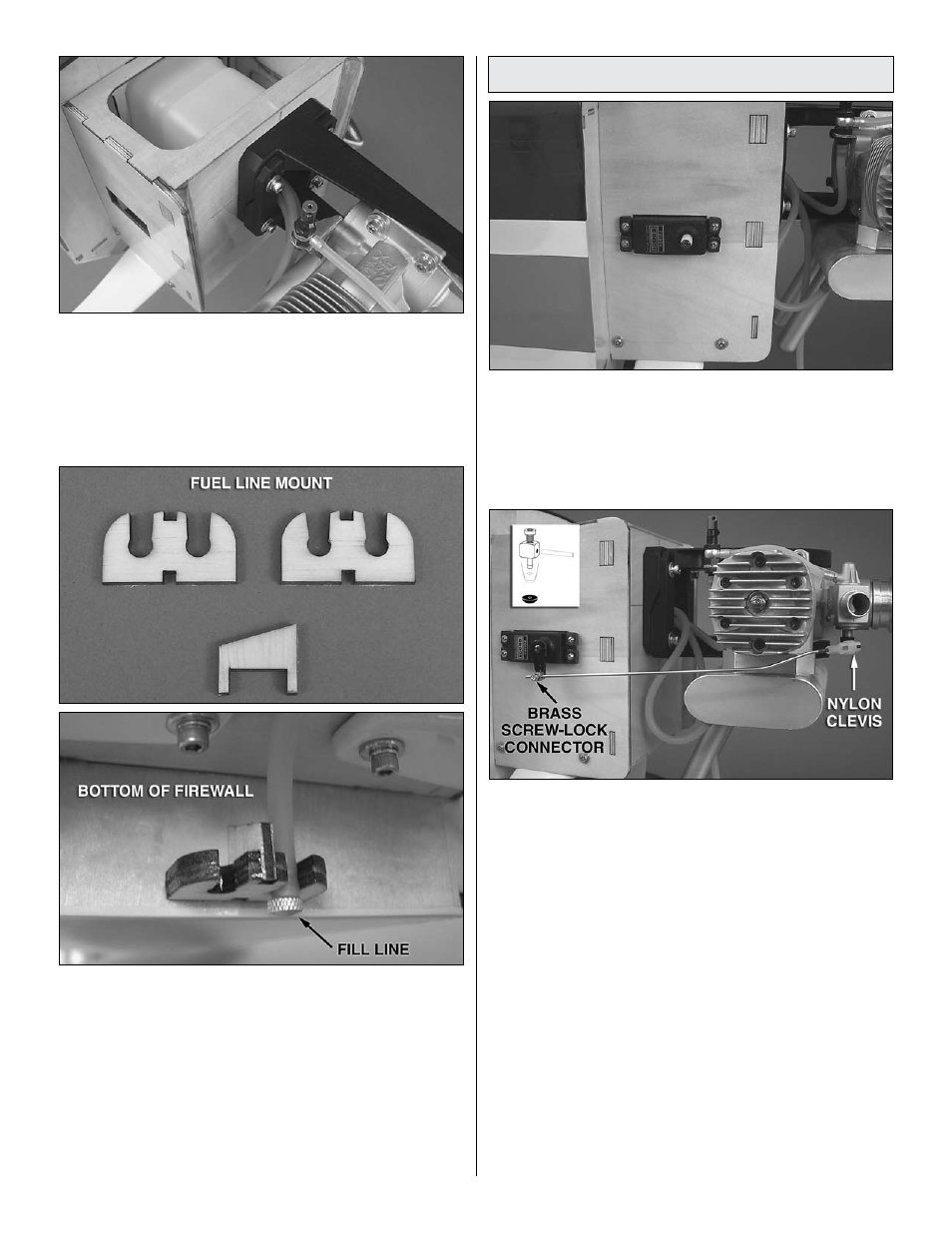

6. Insert the fuel tank into the fuselage as shown with

the neck of the tank pushed as far forward in the hole in the

fuselage as it will fit. The vent line should be at the top of the

tank. Secure the fuel tank inside the fuse by hooking two

of the included rubber bands around the rubber band tabs

as shown. Attach a length of fuel tubing approximately 9"

[229mm] long to each of the fuel tank tubes.

o

7. Cut the fuel tubing on the vent and carb lines to the

necessary length and connect them to the engine. Locate

the three pieces that make the optional

fuel line mount. This

part is used to hold the fill line at the bottom of the firewall (if

an Easy Fueler valve is being used or some similar system,

this part can be omitted). Glue the pieces together as shown.

Use epoxy to fuel proof the part. Sand the bottom center

of the firewall where the part will be glued with 220 grit

sandpaper. Glue the piece in place and clip the fill line into

one of the slots in the fuel line mount. The fill line can now be

cut to length. A fuel line plug is provided for the fill line.

Install the Throttle Servo (glow)

o

1. Attach the throttle servo to the firewall box as shown

using the hardware included with the servo. Be sure to use

thin CA in the servo mounting holes.

o

2. Cut three arms from a four arm servo arm and attach it

to the throttle servo pointing down.

o

3. Install a brass screw-lock pushrod connector using

a nylon retainer to the outer hole in the throttle servo arm.

Loosely install a 4-40 x 1/8" [3mm] SHCS into the brass

screw-lock connector. Install a nylon clevis and silicone clevis

retainer 20 complete turns onto the .074" x 12" [1.9mm x

305mm] pushrod and bend the pushrod to fit from the throttle

servo arm to the carburetor arm. When bending the rod, be

sure there is clearance between the engine/muffler and

the pushrod through the entire travel of the throttle servo.

Metal to metal contact will cause radio interference. When

satisfied, fit the pushrod through the screw-lock connector

and connect the clevis to the carburetor arm. Slide the

silicone clevis retainer to the end of the clevis and make

any necessary adjustments to the pushrod length. Use your

radio system to test the operation of the throttle servo. With

all fine adjustments made, finish tightening the 4-40 x 1/8"

[3mm] SHCS against the pushrod.