Join the wing panels – Great Planes Edge 540 1.60-43cc Performance Series ARF - GPMA1414 User Manual

Page 11

11

inline with the servo arm. Use a T-pin to lightly puncture the

covering to be sure you are over the plywood plate.

o

o

7. Place a heavy-duty

nylon control horn on the

aileron, positioning it as shown in the sketch inline with the

second outer hole of the servo arm. Mark the location for the

screw holes. Drill through the marks you made with a 3/32"

[2.4mm] drill bit (Be sure you are drilling into the plywood plate

mounted in the bottom of the aileron. Drill through the plate

only.

Do not drill all the way through the aileron!). Using

a #4 x 1/2" [13mm] sheet metal screw (there are different

length #4 sheet metal screws included with the model, so

be sure that you are using the correct length screw for this

step), install and then remove a screw into each of the holes.

Harden the holes with thin CA. Install the control horn with

four #4 x 1/2" [13mm] sheet metal screws.

o

o

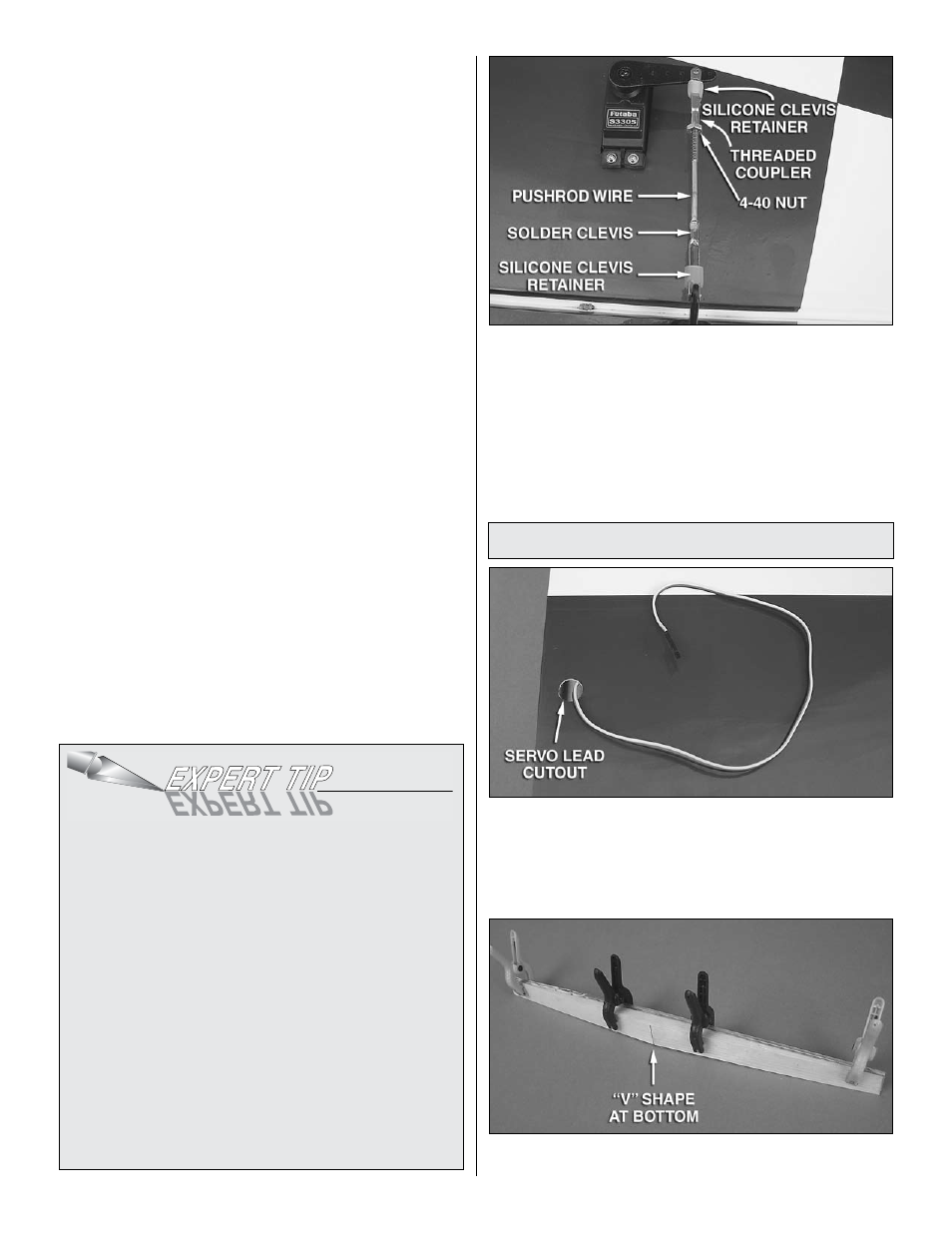

8. Locate a .095" x 6" [2.4mm x 152mm] pushrod wire

threaded on one end. Screw a 4-40 nut, a silicone clevis

retainer and a threaded metal clevis onto the threaded end of

the wire 20 turns. Tighten the nut against the clevis and then

install the clevis on the outer hole of the aileron control horn.

o

o

9. Be sure the aileron servo is centered and the servo

arm is parallel to the hinge line. Install a metal solder clevis

onto the second outer hole in the servo arm. Center the

servo arm parallel with the aileron hinge line and center the

aileron. Using the solder clevis as a guide, mark where to cut

the pushrod wire. Remove the pushrod and clevis from the

control horn and the solder clevis from the servo arm. Install

another silicone clevis retainer onto the wire and solder the

clevis to the pushrod using the

“Expert Tip” that follows.

hOw TO SOLDER ThE CLEVIS TO ThE pUShROD

1. Where the pushrod will make contact with the solder

clevis, roughen the wire with 220-grit sandpaper.

2. Use denatured alcohol to remove any oil residue from

the pushrod wire.

Note: Soldering should be done with

silver solder, not an electrical solder.

3. Apply a couple of drops of flux to the wire. Slide the solder

clevis onto the wire. Using a small torch or soldering iron

heat the wire, allowing the heated wire to heat the solder

clevis. Apply a small amount of solder to the joint. When

the wire and the clevis are hot enough the solder will flow

into the joint. Avoid using too much solder causing solder

to flow out of the joint and clump. Use just enough solder to

make a good joint. Allow the wire and clevis to cool.

4. Put a couple of drops of oil onto a rag and wipe the

joint. This will prevent rust from forming on the joint.

o

o

10. Install the pushrod and clevises to the second

outer hole in the servo arm and the outer hole in the control

horn. Adjust the linkage until the aileron and the servo arm

are both centered. Then tighten the nut against the clevis

with threadlocking compound. Slide the two silicone clevis

retainers to the end of each clevis.

o

11. Repeat these steps for the right wing panel.

Join the wing panels

o

1. Trim the covering from the servo lead cutouts in the

bottom of the wing panels near the root ribs. Feed the aileron

servo leads through the cutouts. Taping the leads to the top

of the wing will keep them out of the way when joining the

wing panels.

o

2. Locate the two aluminum

wing joiner pieces and the

wood wing joiner piece. Use 220 grit sandpaper to thoroughly