Assemble the cowl – Great Planes CAP 232 40 Kit - GPMA0232 User Manual

Page 36

❏

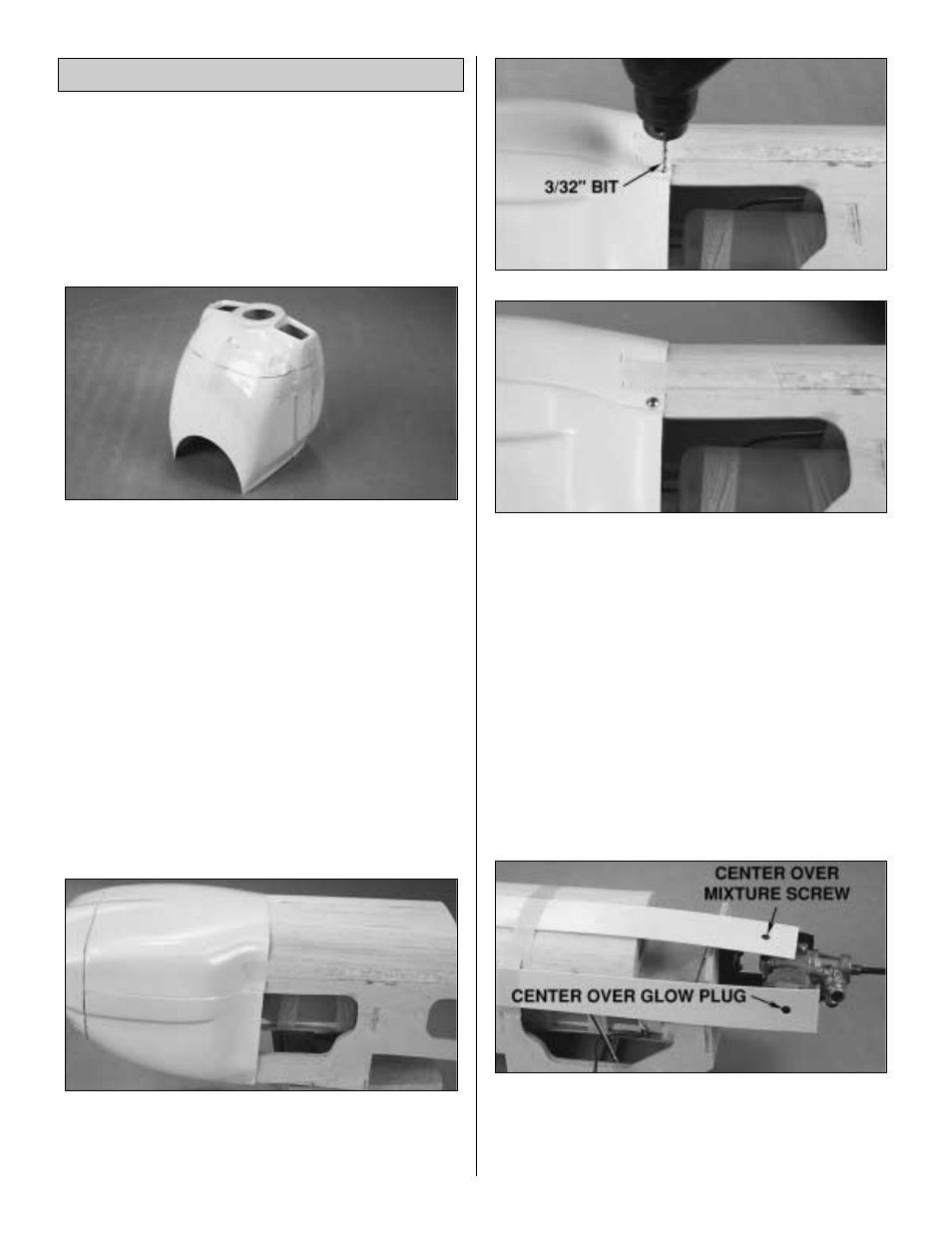

1. The cowl is assembled in a manner similar to the

wheel pants. Cut the cowl along the cut lines, then use your

bar sander to true all the edges. For now, the opening in the

front cowl piece only needs to be roughly cut out. Use

coarse sandpaper to roughen all the overlapping areas so

the glue will stick.

❏

2. Tape the three pieces together, then wick a small

amount of thin CA along the seams of the overlapping

joints. After the CA has cured, remove the tape and make

sure you have thoroughly glued the two pieces together by

inspecting the glue joints and adding thin CA if necessary.

❏

3. Use a sharp hobby knife (or a Moto-Tool with a sanding

drum) to accurately cut the air openings at the front of the

cowl and the air exit at the bottom rear of the cowl.

❏

4. Use 30-minute epoxy to glue a 1" strip of fiberglass

cloth across the glue joint inside the front of the cowl.

❏

5. Fit the cowl over the engine, then mount the spinner

backplate on the engine. Align the cowl so there is

approximately a 1/8" gap between the backplate of the

spinner and the cowl. Tape the cowl to the fuse.

❏

6. Making one hole at a time and checking to be sure the

cowl still lines up with the spinner back plate, drill one 3/32"

hole through the cowl and the fuse side at one of the locations

shown on the plan. Using a #4 x 1/2" screw attach the cowl to

the fuse. Do the same for the other three cowl mounting

screws, checking alignment before drilling each one.

❏

7. Remove the spinner backplate and the cowl from the

fuselage. Use a drop of thin CA to harden the screw holes

in the fuse.

❏

8. Use thin cardboard or plastic to make templates for

the cutouts in the cowl for the glow plug driver and the

needle valve. Tape the templates to the fuselage behind

where the cowl will mount to the fuse, accurately indicating

the position of the glow plug and needle valve.

Assemble the Cowl

36