Great Planes CAP 232 40 Kit - GPMA0232 User Manual

Page 18

B. Use the sharpened tube to

carefully gouge the leading

edge of the aileron. You'll have to make a few cuts to make

the recess deep enough for the torque rod.

❏ ❏

11. Test fit the aileron to the wing to make sure the

torque rod fits and there is approximately 1/16" clearance

between the aileron and the root of the wing with the

aileron aligned at the tip. Make adjustments if necessary.

❏ ❏

12. Mark the location of the hinges on the aileron and

the wing. Cut the hinge slots. Without using glue, test fit the

aileron to the wing with the hinges.

❏ ❏

13. Remove the aileron from the wing. Mark the

"bevel to" lines and shape the leading edge of the aileron to

a "V" as shown on the plan the same way you did for the

elevator and the rudder.

❏

14. Perform the same steps to shape the right aileron

and fit it to the wing.

❏

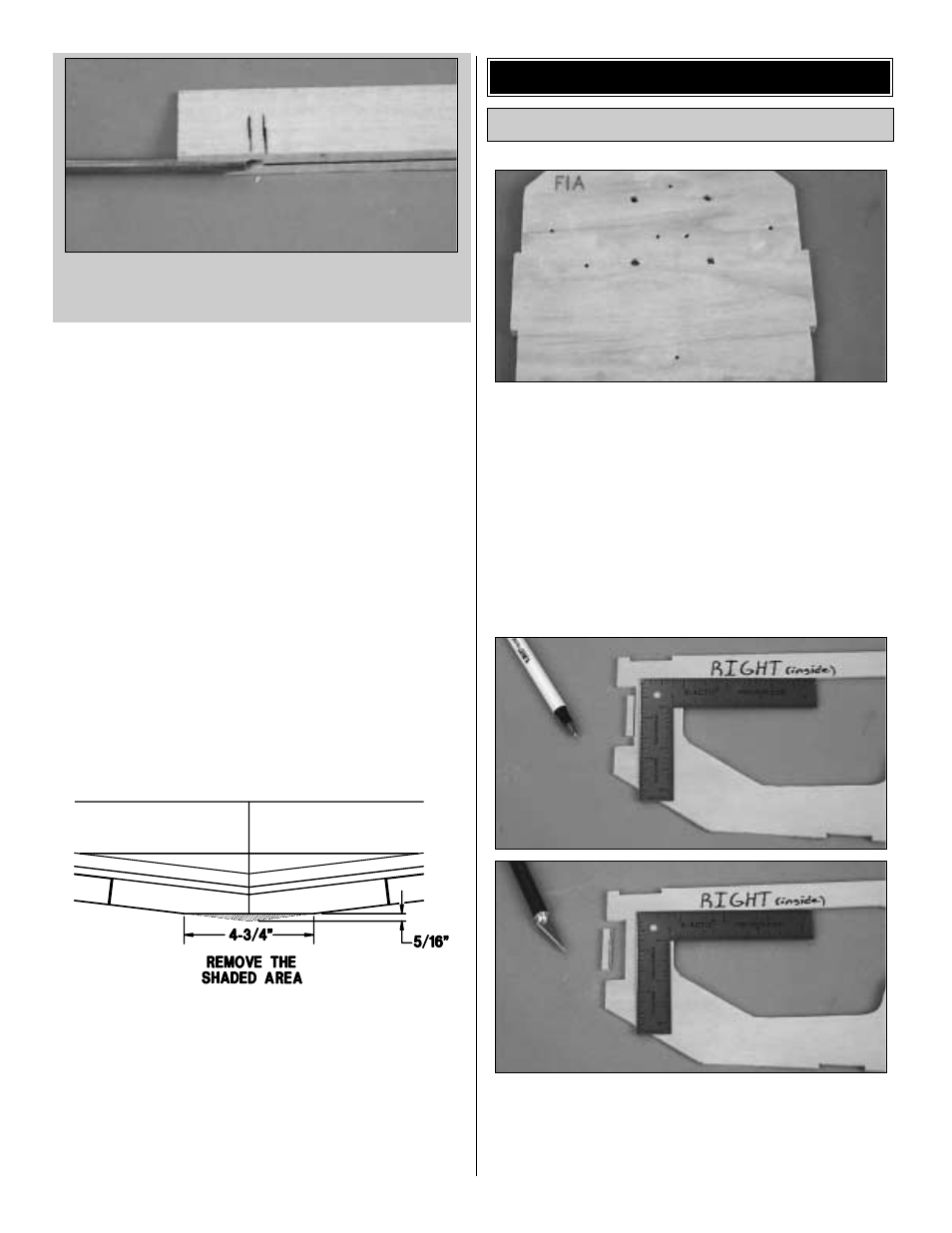

15. Sand approximately 5/16" into the TE at the

centerline. (The flat will end up approximately 4-3/4" wide).

❏

16. Use lightweight balsa filler such as HobbyLite to fill

glue joints or dents in the wing. After the filler has fully dried

use your bar sander to sand the wing using progressively

finer grades of sandpaper so it is smooth and all the joints

are blended.

❏

1. Use 30-minute epoxy to glue the firewall formers

F-1A and F-1B together. Make sure the embossed label on

F-1A is facing UP and the edges and tabs on both formers

are aligned. Wipe away excess epoxy before it cures. From

now on this assembly will be referred to as the firewall.

Note: If the formers are warped, simply clamping them

together may not "cancel out" the warps. It is best to clamp

the formers to a table or a flat board until the epoxy cures.

❏

2. Use a straightedge and a ball point pen to draw a line

across the

tab connecting the notches in the front of only

one of the fuselage sides. Use the line as a guide to

remove the tab with a #11 knife blade. On the inside

surface, label this as the RIGHT fuselage side.

Assemble the Fuse Formers & Sides

BUILD THE FUSELAGE

18