Great Planes CAP 232 40 Kit - GPMA0232 User Manual

Page 35

❏ ❏

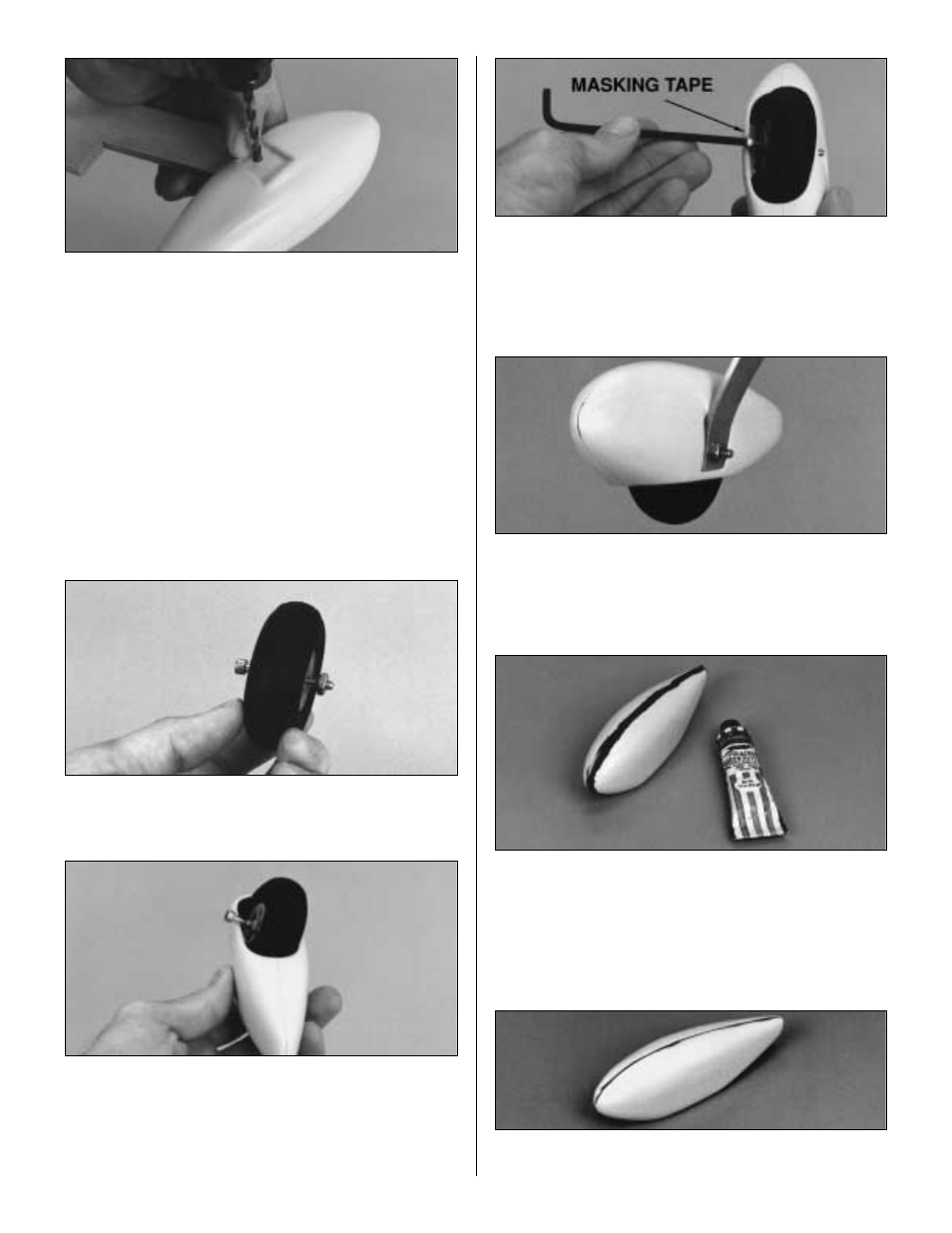

8. Drill a 3/16" (11/64" or #18 for precision) hole in

the wheel pant at the mark. Back up the wheel pant mount

with a piece of scrap wood so you do not split it as the drill

goes through.

❏ ❏

9. Most 2-1/2" wheels are made to fit 5/32" axles, but

the 8-32 screws supplied in this kit for the axles require a

larger hole. If the wheel does not roll freely on the

8-32 x 1-1/2" SHCS "axle," enlarge the wheel hub with an

11/64" (#18 for perfection) drill.

❏ ❏

10. Test fit the wheel in the wheel pant using the

following procedure:

A. Install an axle in a wheel. Thread an 8-32 nut about 1/8"

onto the axle.

B. Insert the wheel in the pant with the end of the screw

inserted in the plywood wheel pant mount and the head of

the screw sticking out of the wheel pant.

Note: When you reinstall the wheel after the wheel pant

has been painted, put masking tape on the bottom of the

pant so the screw will not scratch it.

C. Use a 9/64" hex wrench to screw the axle through the

wheel and the wheel pant until the wheel goes all the way

in and the axle goes through the pant mount.

D. Adjust the tightness of the nut with hemostats or needle

nose pliers.

❏ ❏

11. Temporarily mount the wheel pant to the landing

gear with another 8-32 nut on the axle.

❏

12. Perform the same procedure to assemble and

temporarily mount the other wheel pant to the landing gear.

❏

13. Before painting the wheel pants, fill the seams with

putty filler such as Squadron White Putty or resin filler such

as Bondo.

®

We use Bondo most of the time as it cures

quickly and is easy to sand, but usually it must be

purchased in large quantities. Squadron putty works well

but it takes overnight to dry and usually requires at least

two applications because it shrinks as it dries.

❏

14. After the filler cures, wet sand the wheel pants with

400-grit sandpaper to prepare them for primer.

35