Final assembly – Great Planes Spirit 2-Meter Sailplane Kit - GPMA0530 User Manual

Page 25

merit and wedge the other one between the sides in the weight

compartment. These pieces arc called the Canopy Aligners.

Lift the aligners so that they are slightly above the sides.

Apply a small drop of thick CA to the middle of each aligner

and carefully slide the canopy into place. Push down on the

canopy to force the aligners against the canopy base (with the

canopy aligned with the fuselage sides) and hold it until the

glue has cured (a couple of minutes). Carefully remove the

canopy and securely glue the aligners to the canopy base with

more CA.

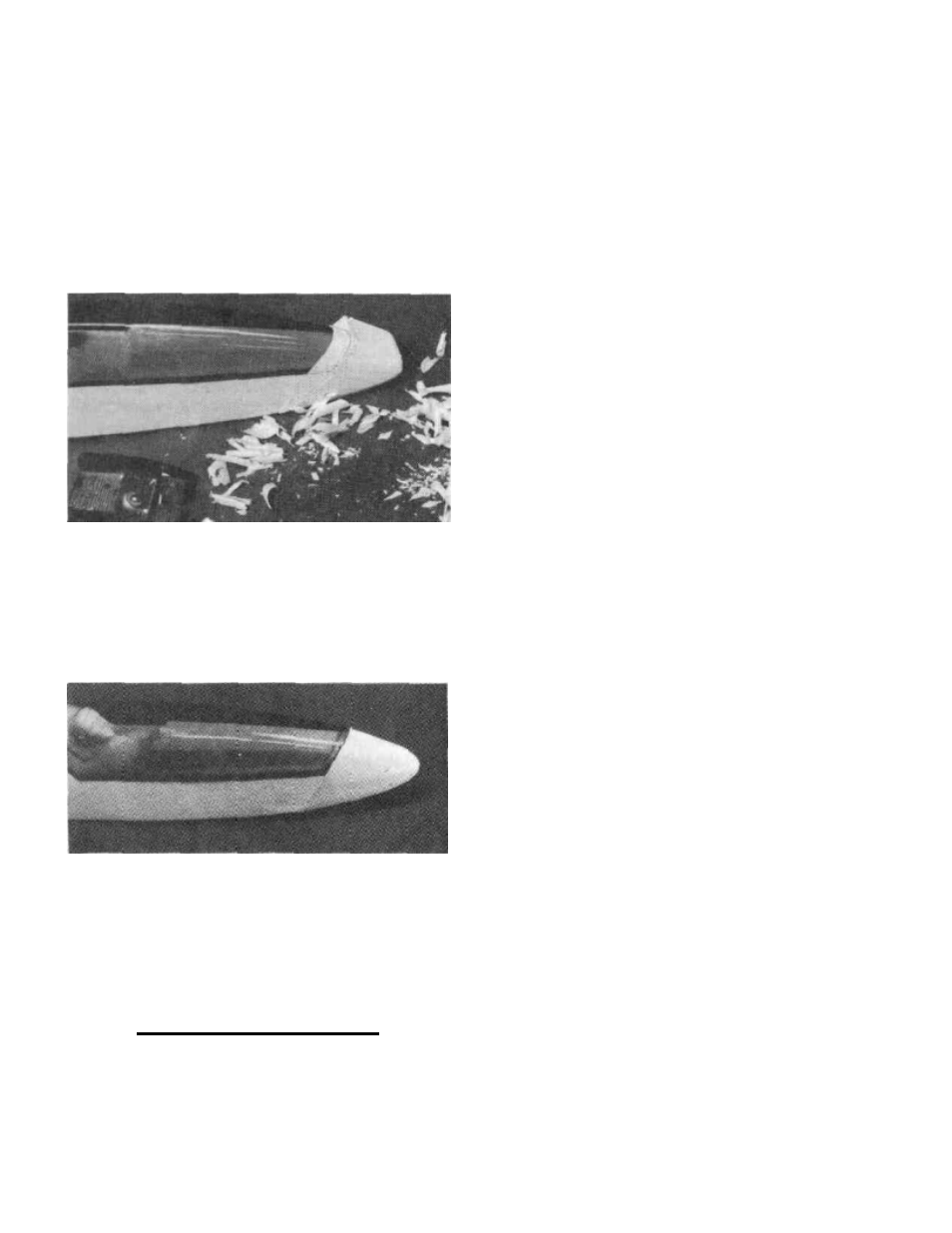

D 13. Apply a couple strips of masking tape around the

front of the canopy to protect the plastic and install the canopy

on the fuselage. Use a razor plane, hobby knife or sanding

block with coarse grit sandpaper to rough carve the nose

block to shape.

D 14. Use your sanding block with medium and then fine

grit sandpaper to smooth out the nose block and fair it in with

the canopy and the fuselage.

FINAL ASSEMBLY

BALANCE THE AIRPLANE LATERALLY

SPECIAL NOTE: Do not confuse this procedure

with "checking the C.G." or "balancing the air-

plane fore and aft". That very important step

will be covered later in the manual.

Now that you have the basic airframe nearly completed,

this is a good time to balance the airplane laterally (side-to-

side). Since the wing is the major factor on a sailplane, we

will only be concerned with it. Here is how to do it:

1.

Set the wing on a flat surface and hold it so that both

wing tips are level. Let go of the wing and notice which wing

tip drops. Do this several times and if the same wing tip keeps

dropping push a thumb tack or small nail through rib W 10 into

the wing tip that keeps rising.

2. Perform

this

test

several

times until the wing bal-

ances or the same wing tip does not drop every time and then

glue the tacks or nails in place with a drop of thin CA.

FINAL SANDING

Check over the entire structure carefully, inspecting for

any poorly glued joints, gaps and "dings". Apply additional

glue and/or balsa filler as necessary, then sand the entire

structure smooth using progressively finer grades of sandpa-

per. Sand the fuselage corners to a rounded shape as shown

on the cross sections of the plans.

COVERING

There are many different types of covering materials

available these days but the iron-on type coverings are by far

the easiest to use and in most cases the best suited for the job.

There are also several different brands of iron-on coverings

available. We recommend you use Top Flite Super

Monokote for covering your SPIRIT due to this covering's

higher strength. Sailplanes,

which usually have higher

"aspect ratio" wings (long and thin), gain a great deal of

strength from the covering. This is evident by gently twisting

the wing before and after it is covered, it is hard to believe the

difference. Because of this, the higher strength coverings are

best suited for sailplanes.

The following are some covering tips we have learned

over the years but you should follow the instructions in-

cluded with your covering material.

• Sand the surfaces as smooth as possible before starting to

cover the plane. The finished covering job will only be as

smooth as the surface you started with.

• Use a fresh single-edge razor blade or hobby knife blade

and replace the blade as soon as it starts showing signs of

dulling.

• Set the iron to the proper temperature by first applying a

25 "test strip" on a scrap of balsa.