Great Planes Spirit 2-Meter Sailplane Kit - GPMA0530 User Manual

Page 17

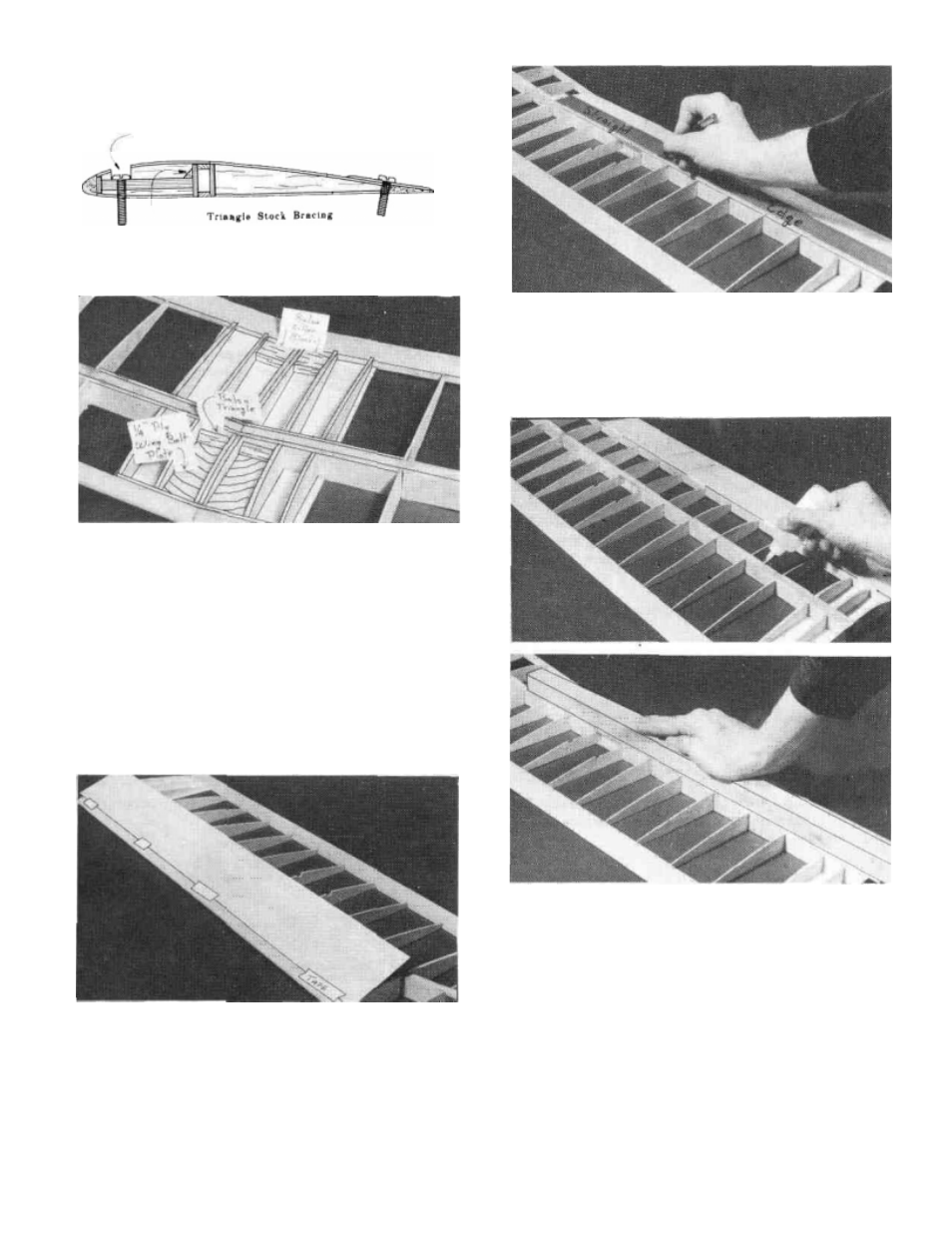

-Cut W1A Rib and Leading Edge Sheeting

away to clear Nylon Wing Bolt

D 14. Add a 5/16" x 1" x 7/8" balsa filler block (not

included) on each side of the middle W1B ribs near the

trailing edge and sand them flush with the top of the ribs.

STEPS 15 - 18 APPLY TO ALL WING

CONFIGURATIONS

and act as a lunge for the gluing process. Press the sheeting

into place and trim it flush with the back edge of the spar using

a modeling knife and straightedge.

D 17. Lift the sheeting up and apply a bead of thick CA

along the top spar. Quickly press the sheeting down into place

and hold until the glue has cured. A straight strip of wood the

length of the panel can be a big help when trying to hold the

sheeting down evenly.

D 15. Set the 1/16" x 3" x 24" Balsa Leading Edge

Sheeting (SPRTW17)in place on the inner panel. The outer

end of the sheeting should cover rib W3A. Cut off the excess

sheeting even with rib W1A. Sand the top L.E. of the ribs if

necessary to allow the sheeting to be flush with the L.E.

D 16. With

the 1/16" sheeting in place against the leading

edge apply several strips of masking tape to hold it in place

D 18. Apply a small bead of thin CA between the pieces of

masking tape along the leading edge. When all of the glue has

cured, remove the tape, flip the wing over and securely glue

the sheeting to the ribs using thin CA as shown in the photo

at the top of the next page. Poke some pin holes in the center

sheeting where the center W1A rib is and apply a drop of thin

CA to each hole.

17