Carl Goldberg GBGA1064 User Manual

Page 12

12

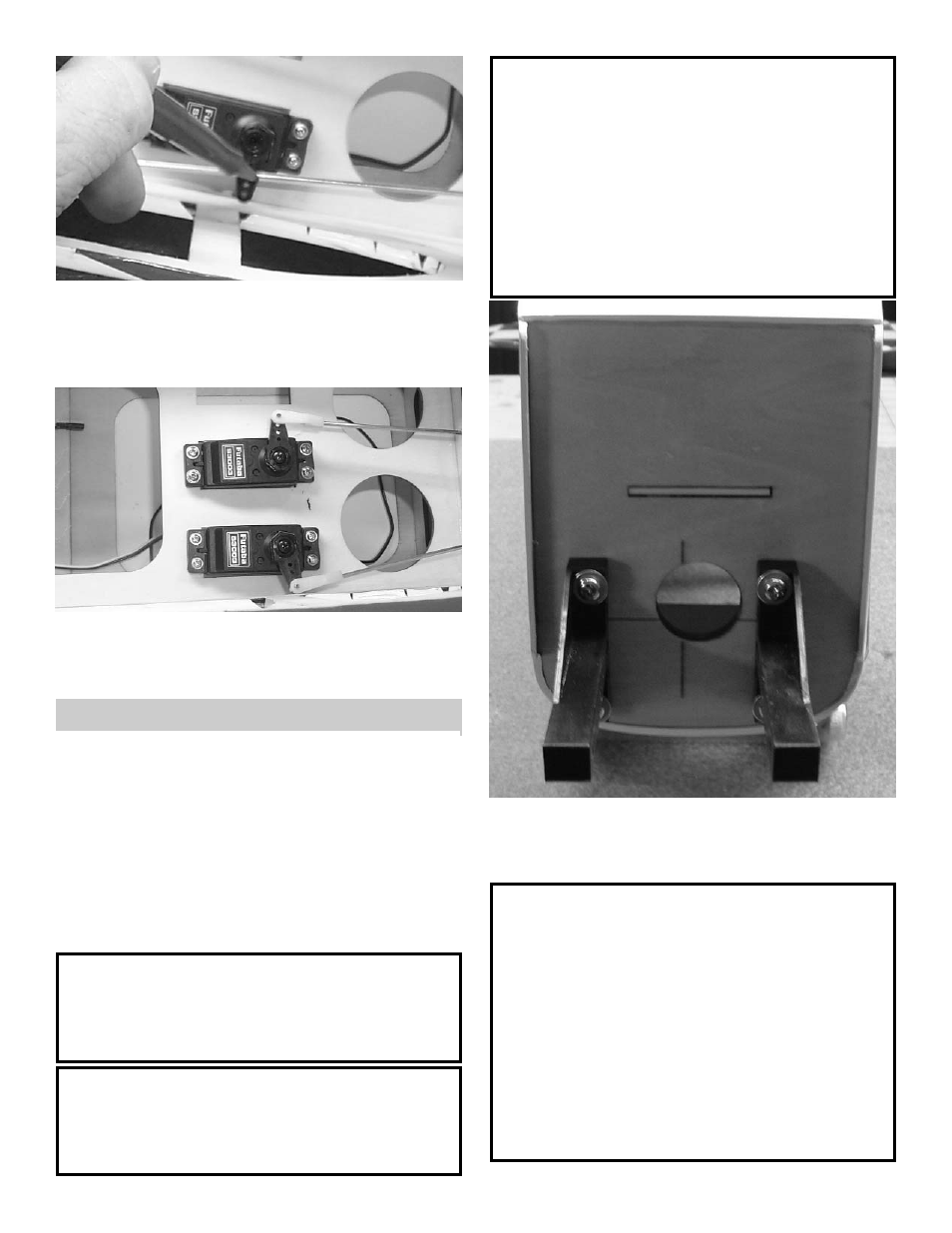

3.

Measure the length of the pushrod to the

servo arm hole and make a 90 degree bend.

Mount the swivel keeper on to the wire and

clip in place.

4.

Repeat steps 2 & 3 for the rudder servo.

The servo should look the same as above

when finished.

INSTALLING THE ENGINE

1.

Collect the following items:

(2) Motor Mounts

(1) Engine

(4) 8-32 x 3/4” Philip Head Screw

(4) 8-32 x 1” Philip Head Screw

(4) #8 Washer

(4) 8-32 Nylon Locking Nut

Note:

Your engine installation may be dif-

ferent then shown depending on the

motor you use.

Caution:

Always use thread lock on any type

of machine bolt and nut.

Note:

This installation is for a inverted

mounted engine. If you wish to have

a side mounted engine, then your

installation steps may be different.

You also might need

a round style motor mount and not

use the one beam mounts supplied in

this kit..

2. Using thread lock, mount the motor mounts to

the firewall using 8-32 x 3/4” screws with #8

washers.

Note:

The firewall is pre-drilled so that the

mounts have an opening of 1.67” this

will fit a O.S. 70 Surpass up to a O.S.

90 Surpass. The motor you choose

might require a different spacing. The

blind nuts can be removed and

changed if required.