AERCO KC Standard to Low NOx Convertion Instructions User Manual

Page 40

40

NOTE

Always approach a firing rate percentage from the same direction, (i.e., 100%

to 25%, 25% to 20%, etc.). Whenever going to an increased firing rate from

below (i.e., 25% to 30%), first go above and then back down to the desired

firing rate. This is necessary due to hysteresis in the air/fuel stepper motor.

Hysteresis causes the air/fuel valve to stop in a slightly different position if the

firing rate percentage is approached from below or above. This results in a

difference in oxygen readings for the same firing rate percentage causing

unnecessary recalibration.

8. Allow enough time for the combustion analyzer to settle. Compare the measured oxygen level

to the oxygen range for intake air temperature in Table 4. Also, ensure that the carbon

monoxide (CO) and nitrogen oxide (NOx) readings do not exceed the values shown.

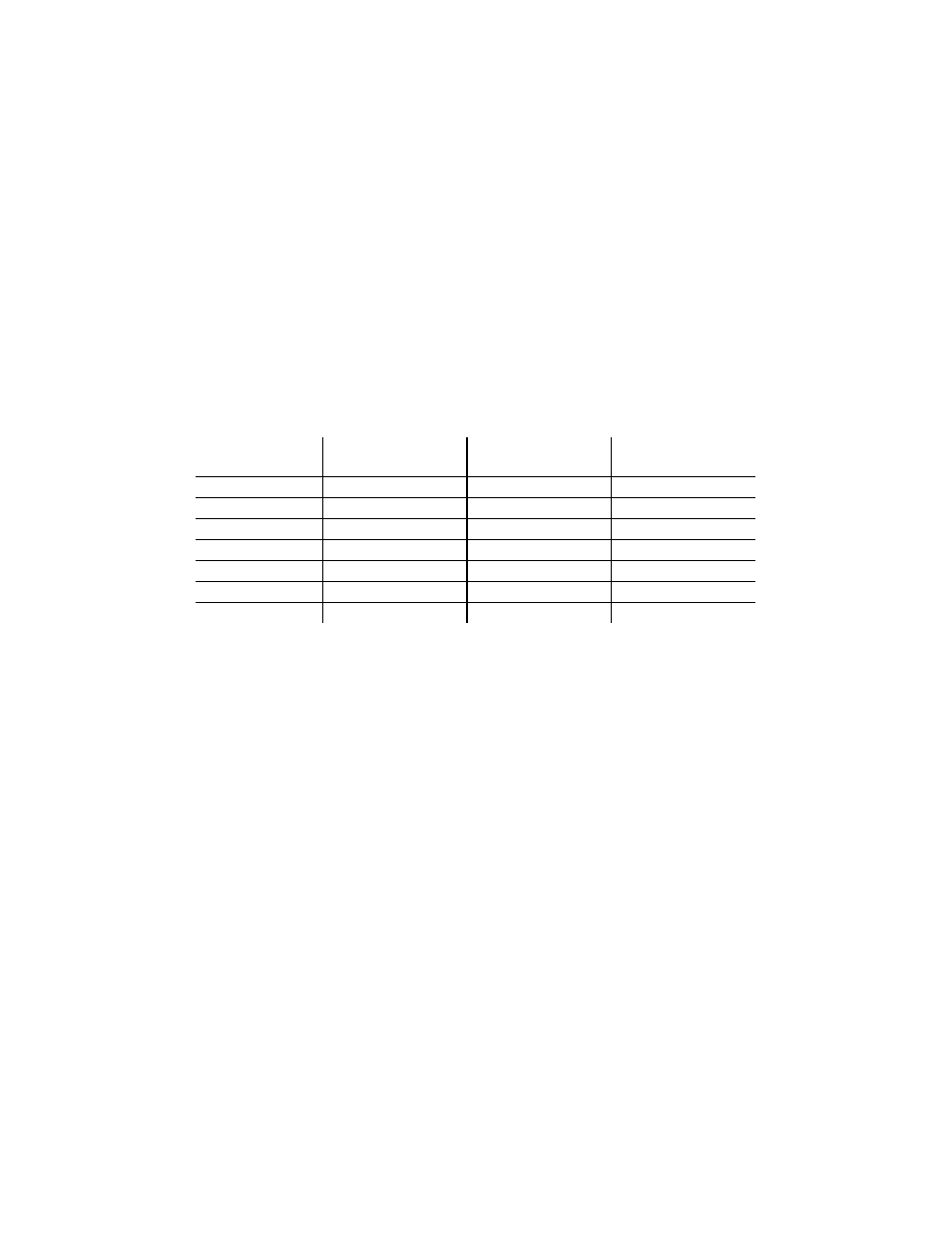

Table 4

Combustion Oxygen Levels for a 25% (2.0V) Firing Rate

Inlet Air

Temp

Oxygen

(±0.2%)

Carbon

Monoxide

*NOx

40°F

6.7 %

<100 ppm

<23.8 ppm

50°F

6.5 %

<100 ppm

<24.1 ppm

60°F

6.3 %

<100 ppm

<24.4 ppm

75°F

6.0 %

<100 ppm

<24.9 ppm

85°F

5.7 %

<100 ppm

<25.4 ppm

90°F

5.6 %

<100 ppm

<25.6 ppm

100°F

5.4 %

<100 ppm

<25.9 ppm

*Tabulated data are uncorrected ppm NOx values and will be less than or equal to 30 ppm of

NOx when corrected to 3% oxygen.

9. If the measured oxygen level, CO and NOx emissions are within the ranges shown in Table 4,

no adjustment is necessary. Proceed to step 14.

10. If the measured oxygen level is below the range in Table 4, rotate the differential regulator

adjustment tool counterclockwise 1/4 to 1/2 revolution to decrease gas flow.

11. Wait for the combustion analyzer to settle, then compare the new oxygen reading to Table 4.

Repeat adjustment until oxygen is within the specified range.

12. If the measured oxygen level is above the oxygen range in Table 4, rotate the differential

regulator adjustment tool clockwise 1/4 to 1/2 revolution to increase gas flow.

13. Wait for the analyzer reading to settle, then compare the new reading to Table 4. Repeat

adjustment until oxygen is within the specified range.

NOTE

Adjust only the differential regulator at 25% (2.0V) control signal; do not adjust

the air shutter.

14. Once the oxygen level is within the specified range at 25% (2.0V), change the firing rate to

10% (1.4V).