Section 7 - maintenance, 1 maintenance schedule, 2 spark ignitor – AERCO KC1000 Boiler equipped with C-More version 3.04 User Manual

Page 51: Warning, Caution, Table 7-1. maintenance schedule

MAINTENANCE

SECTION 7 - MAINTENANCE

7.1 MAINTENANCE SCHEDULE

The unit requires regular routine maintenance to

keep up efficiency and reliability. For best opera-

tion and life of the unit, the following routine

maintenance procedures should be carried out in

the time periods specified in Table 7-1.

Appendix J contains recommended spare parts

lists for maintenance of the KC1000 Boiler.

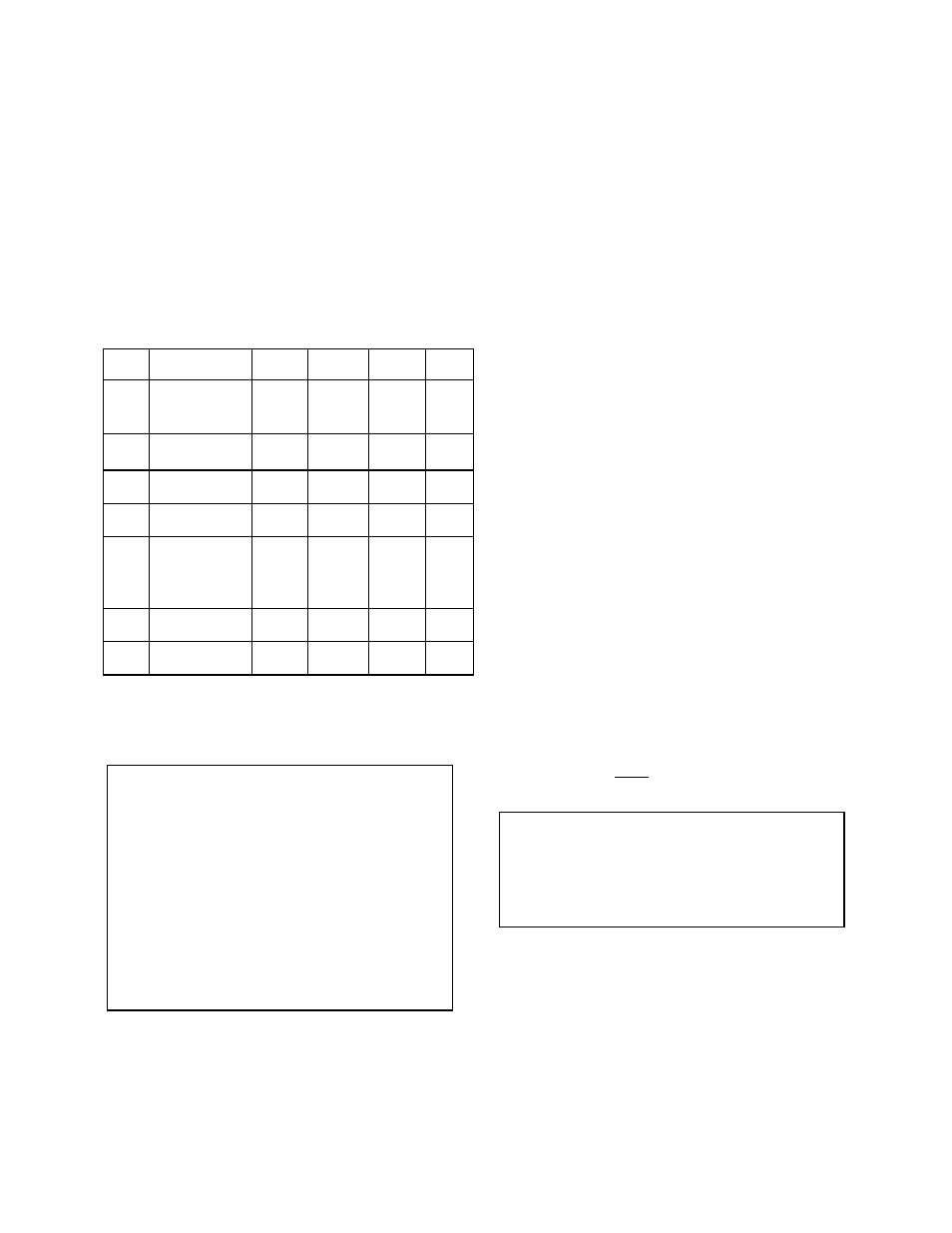

Table 7-1. Maintenance Schedule

Sect

Item

6

Mos.

12

Mos.

24

Mos.

Labor

Time

7.2 Spark

Ignitor

(GP-122435-S)

Inspect

Replace

15

mins.

7.3 Flame

Detector

(GM-123428)

Inspect Replace

15

mins.

7.4 Combustion

Adj.

Check Check

1 hr.

7.5 Testing

of

Safety Devices

Test

20

mins.

7.6 *Manifold

&

Tubes

Inspect

& clean

if

neces-

sary

4 hrs.

7.7 Water

Side

Inspection

Inspect 2

hr.

7.8 Condensate

Drain

Inspect

Inspect

& Clean

30

mins.

* Recommended only when unit will be run in an

extreme condensing mode for prolonged periods

of time.

WARNING!

TO AVOID PERSONAL INJURY, BEFORE

SERVICING:

(A) DISCONNECT THE AC SUPPLY BY

TURNING OFF THE SERVICE SWITCH

AND AC SUPPLY CIRCUIT BREAKER

(B) SHUT OFF THE GAS SUPPLY AT THE

MANUAL SHUT-OFF VALVE PROVIDED

WITH THE UNIT

(C) ALLOW THE UNIT TO COOL TO A

SAFE TEMPERATURE TO PREVENT

BURNING OR SCALDING

7.2 SPARK IGNITOR

The spark ignitor assembly (part no.

GP-122435-S) is located in the body of the

burner (see Figure 7.1). The ignitor may be

HOT. Care should be exercised. It is easier to

remove the ignitor from the unit after the unit has

cooled to room temperature.

To inspect/replace the Ignitor :

1. Set

the

ON/OFF switch on the control panel

to the OFF position and disconnect AC

power from the unit.

2.

For access to the spark ignitor

(GP-122435-S), remove the unit’s right side

panel. Access can also be gained by

removing the rear panels and condensate

drainage system

3. Disconnect the ignitor cable from the ignitor

extension. Remove the silicone ignitor plug

from the burner shell by simultaneously

twisting and pulling downward.

4. Insert the ignitor removal tool into the burner

shell, where the ignitor plug was removed.

Screw the outer barrel of the tool into the

burner shell. Push the inner barrel up and fit

the hexagonal end of the tool over the

ignitor. Unscrew the ignitor from the burner

head and then the tool from the burner shell.

5. The ignitor is gapped at 1/8-inch. If there is a

substantial erosion of the spark gap or

ground electrode, the ignitor should be re-

placed. If carbon build-up is present, clean

the ignitor using fine emery cloth. Repeated

carbon build-up on the ignitor is an indication

that a check of the combustion settings is

required (see Section 4 for Combustion

Calibration).

6. Prior to reinstalling the ignitor, an anti-seize

compound must be applied to the ignitor

threads.

CAUTION!

The ignitor must be removed and installed using

the ignitor removal tool provided with the unit(s).

Damage to the burner due to using a socket for

removal and installation of the ignitor is not

covered under warranty.

7. Reinstall the ignitor assembly using the

ignitor removal tool. Do not over tighten the

ignitor. A slight snugging up is sufficient.

8. Reinstall the ignitor plug into the burner shell

by simultaneously twisting and pushing it into

the shell.

9. Reattach the ignitor cable to the extension

and verify that it “clicks” into place.

7-1