3 pressure relief and drain valve installation, 4 temperature/pressure indicator, Installation – AERCO KC1000 Boiler equipped with C-More version 3.04 User Manual

Page 13

INSTALLATION

Every boiler plant must have a source of make-

up water to it. As with any closed loop hydronic

system, air elimination and expansion equip-

ment must be provided as part of the overall

installation. All piping MUST include ample

provision for expansion.

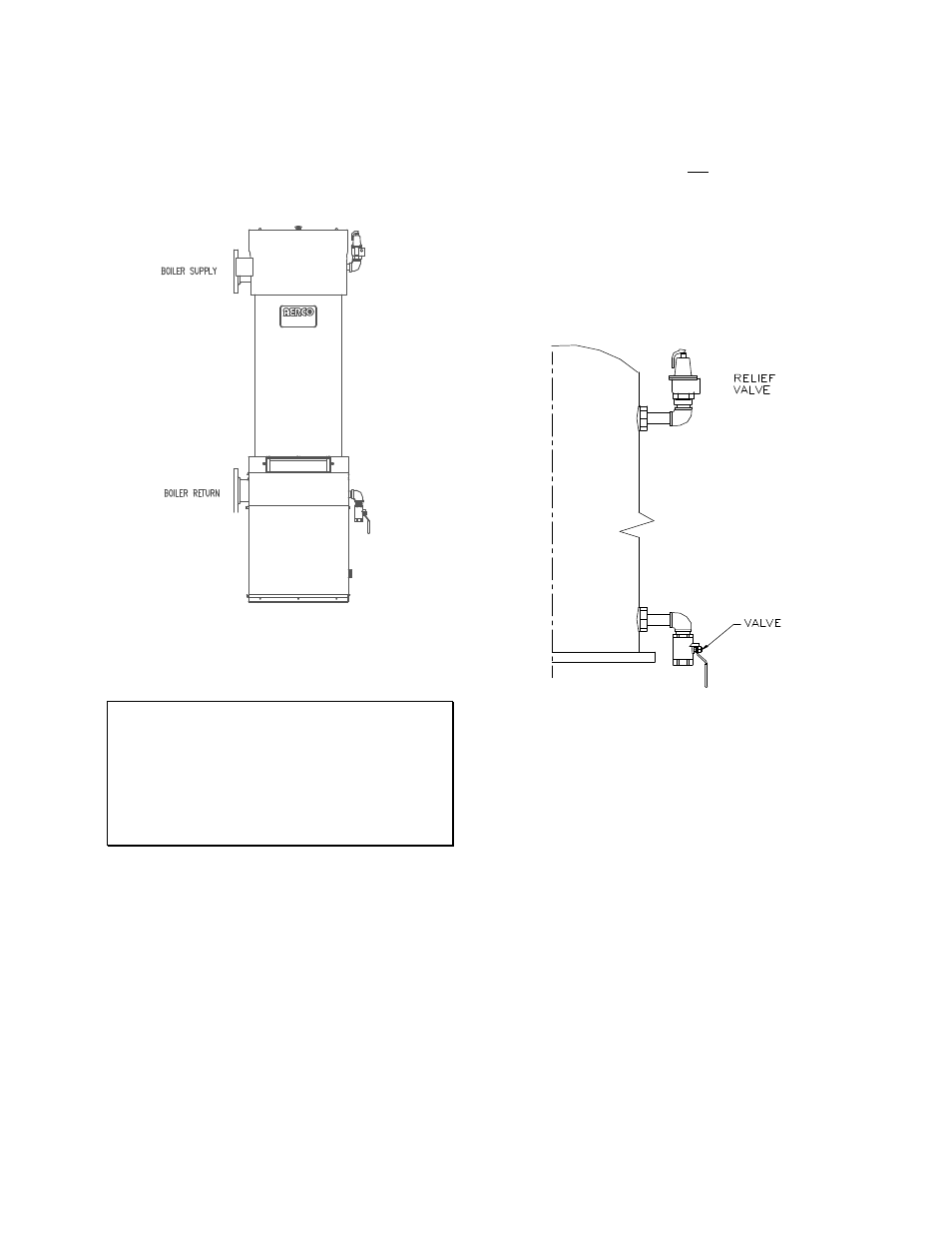

Figure 2.3

Supply and Return Location

NOTE:

The maximum working pressure for

installations within the Province of Alberta is

87 psig. Therefore a pressure relief valve

with a setting of 75 psig (or lower) should be

installed for these installations. See Drawing

AP-A-863 in Appendix F.

2.3.3 PRESSURE RELIEF AND DRAIN

VALVE INSTALLATION

An ASME rated Relief Valve is supplied with

each unit. The supplied pressure relief valve

setpoint will be 30, 50, 75, 100, or 150

psig as

ordered from the factory. Install the pressure

relief valve in the tapping provided opposite the

system supply connection, (see Figure 2.4). The

pressure relief valve should be piped in the

vertical position

using the fittings supplied. A

suitable pipe compound should be used on the

threaded connections, and excess should be

wiped off to avoid getting any into the valve

body. The discharge from the relief valve should

be piped to within 12 inches of the floor to

prevent injury in the event of a discharge.

The relief piping must be full size without

reduction. No valves, restrictions, or other

blockages should be allowed in the discharge

line. In multiple unit installations the relief valve

discharge lines must not be manifolded,

(connected), together. Each must be individually

run to a suitable discharge location. The drain

valve provided should be installed on the right

hand side of the unit towards the bottom of the

shell. The valve should be pointed in the down

position, (see Figure 2.4).

Figure 2.4

Relief and Drain Valve Location

2.3.4 TEMPERATURE/PRESSURE

INDICATOR

The unit is supplied with one of two styles of

Temperature/Pressure Indicators that must be

installed in the tapping on the supply flange of

the unit (see Figures. 2.5a and 2.5b). A suitable

pipe compound should be used sparingly to the

threaded connection.

2-3