Section 6 - safety device testing procedures, 1 testing of safety devices, 2 low gas pressure test – AERCO KC1000 Boiler equipped with C-More version 3.04 User Manual

Page 45: 3 high gas pressure test

SAFETY DEVICE TESTING

SECTION 6-SAFETY DEVICE TESTING PROCEDURES

6.1 TESTING OF SAFETY DEVICES

Periodic testing of all controls and safety devices

is required to insure that they are operating as

designed. Precautions must be taken while tests

are being performed to protect against bodily

injury and property damage.

Systematic and thorough testing of the operating

and safety controls should be performed on a

scheduled basis, or whenever a control compo-

nent has been serviced or replaced. All testing

must conform to local jurisdictions or codes such

as ASME CSD-1.

NOTE:

MANUAL and AUTO modes are required to

perform the following tests. For a complete

explanation of these modes, see Section 3.

NOTE:

It will be necessary to remove the sheet

metal covers and cap from the unit to

perform the following tests.

WARNING!

ELECTRICAL VOLTAGES IN THIS

SYSTEM INCLUDE 120 AND 24 VOLTS

AC. POWER MUST BE REMOVED PRIOR

TO PERFORMING WIRE REMOVAL OR

OTHER TESTING PROCEDURES THAT

CAN RESULT IN ELECTRICAL SHOCK.

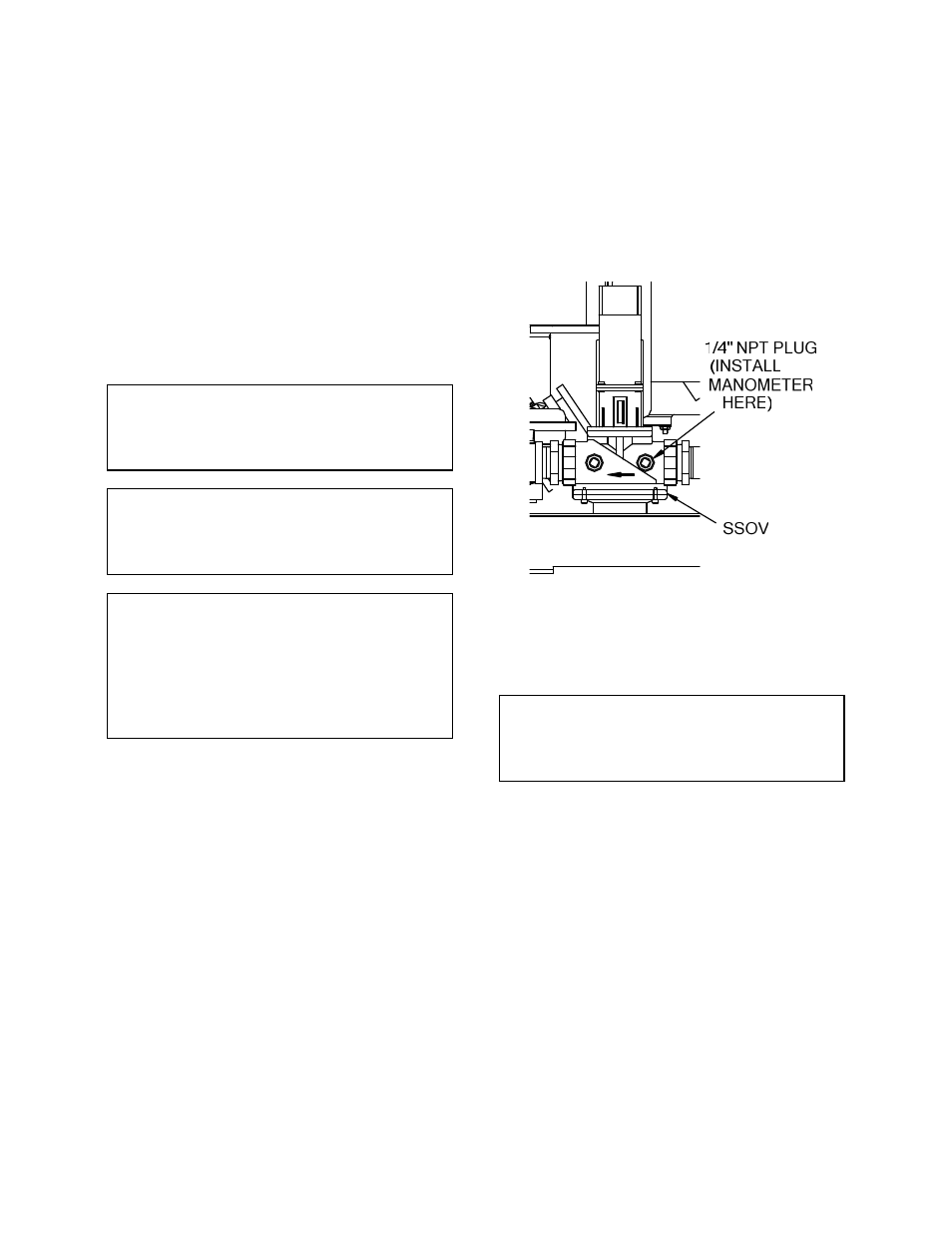

6.2 LOW GAS PRESSURE FAULT TEST

1. Shut off the gas supply to the unit.

2. Install a 0-16” W.C. manometer in the gas

pipe assembly below the low gas pressure

switch. (See Fig. 6.1)

3. Open the gas supply to the unit and depress

the CLEAR button to clear any fault

messages..

4. Place the unit in Manual Mode and fire the

unit at a valve position between 25% and

30%.

5. Slowly close the manual gas supply valve

while monitoring the gas pressure. The unit

should fault and shutdown on LOW GAS

PRESSURE when the manometer indicates

approximately 6.5” W.C.

6. Open the gas supply to the unit and press

the CLEAR button on the Control Box.

7. The unit should restart.

Figure 6.1

1/8” Pipe Plug Position for Manometer

Installation

NOTE:

After faulting the unit, the fault message will

be displayed and the fault indicator light will

flash until the CLEAR button is pressed.

6.3 HIGH GAS PRESSURE TEST

1. Start the unit in manual mode and fire

between 25% and 30%.

2. Remove either wire # 150 or wire #151 from

the high gas pressure switch. See Fig. 6.2.

3. The unit should shut down on a HIGH GAS

PRESSURE FAULT.

4. Reconnect the wire previously removed from

the high gas pressure switch and depress

the CLEAR button.

5. The unit should restart.

6-1