1 pilot regulator pressure testing – AERCO BMK 6000 User Manual

Page 95

Benchmark 6000 Boiler Installation, Operation & Maintenance Manual

CHAPTER 7 – MAINTENANCE

OMM-0086_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 95 of 210

GF-133

Ph.: 800-526-0288

03/20/14

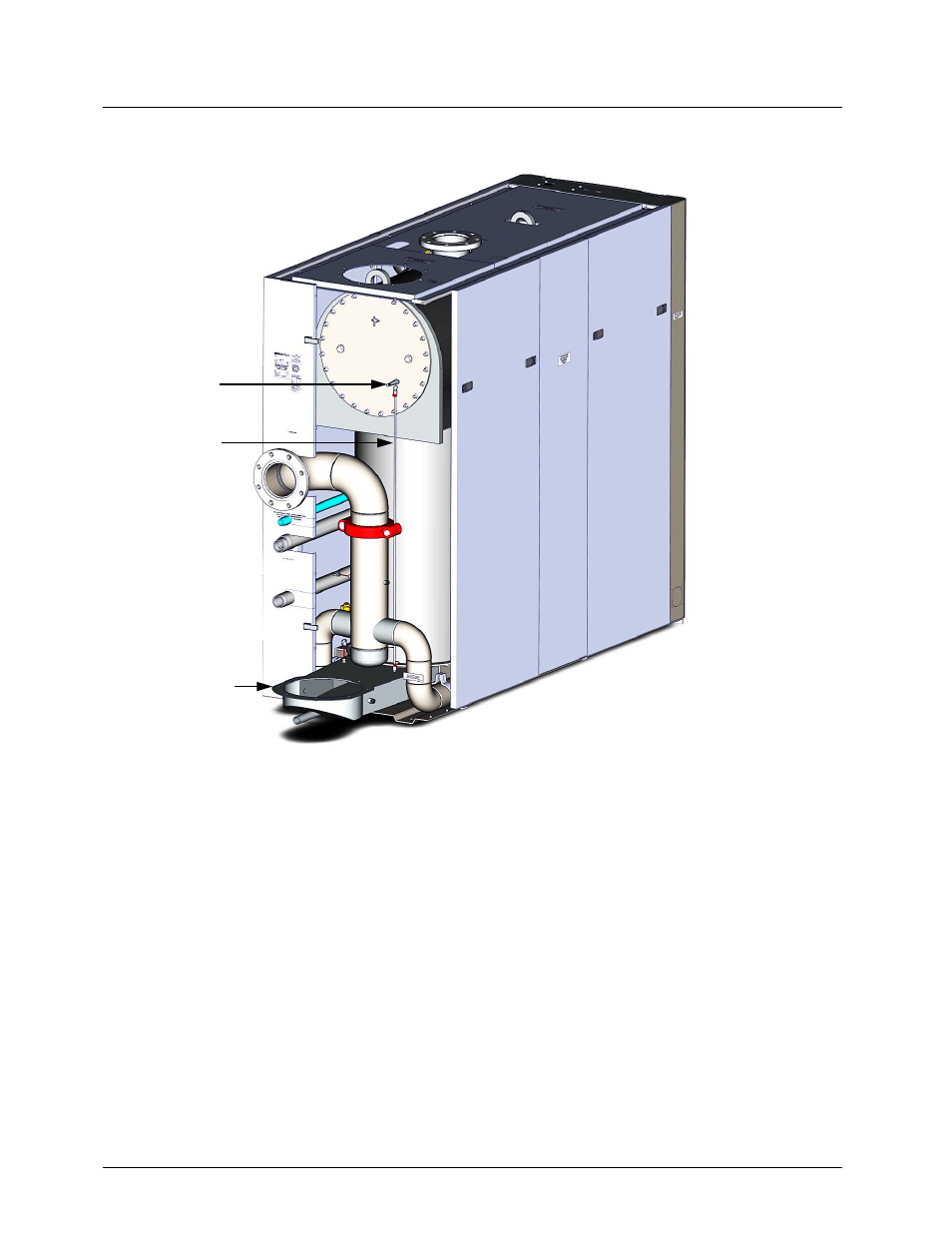

Figure 7-2: O

2

Sensor Mounting Location

7.5 COMBUSTION CALIBRATION & PILOT REGULATOR ADJUSTMENT

Combustion settings must be checked at the intervals shown in Table 7-1 as part of the

maintenance requirements. Refer to Chapter 4 for combustion calibration instructions. Pilot

Regulator tests and adjustments are performed using the procedures in sections 7.5.1 and 7.5.2

which follow.

7.5.1 Pilot Regulator Pressure Testing

The BMK6000 unit has a Pilot Regulator system in the gas train that should be pressure tested

annually as described in the following procedure. However, if the pressure is above 5.0” W.C. or

below 4.0” W.C., then the Pilot pressure regulator must be recalibrated using the instructions

provided in section 7.5.2.

The Pilot Regulator pressure test is performed as follows:

O

2

SENSOR

GAS SUCTION

LINE FROM

EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

- AERClean (12 pages)

- ProtoNode Gateway Rev 1 (with internal LEDs) (64 pages)

- ProtoNode Gateway Rev 3 (with external LEDs) (126 pages)

- Control System (ACS) (144 pages)

- Belimo F6...HD/HDU Series Valve (44 pages)

- Belimo AF120-S US Actuator (9 pages)

- Belimo AMX24-MFT Actuator (9 pages)

- Belimo GKX24-MFT Actuator (9 pages)

- Belimo Motorized Valves Installation (20 pages)

- BMS II BOILER (108 pages)

- BMS II BOILER MODBUS Communication (100 pages)

- BMS 168 (86 pages)

- Boiler Valve Controller (BVC) PRIOR to Serial-12-840-1 (35 pages)

- Boiler Valve Controller (BVC) (38 pages)

- Buffer Tanks (14 pages)

- Combination Control Panel (CCP) (4 pages)

- XPC GATEWAY Communications (193 pages)

- Domestic Water Storage Tank (19 pages)

- Steam Traps (6 pages)

- X100 – Inhibitor (4 pages)

- AM Series Boiler User Manual (156 pages)

- AM Series Boiler Cascade Sequencer Controller (26 pages)

- AM Series Boiler Modbus Interface Manual (18 pages)

- BMK 1.5 LN October 2012 (166 pages)

- BMK 1.5 LN July 2011 (152 pages)

- BMK 1.5 LN June 2010 (123 pages)

- BMK 1.5 LN May 2009 (111 pages)

- BMK 1.5 LN Dual Fuel Feb 2013 (162 pages)

- BMK 1.5 LN Dual Fuel June 2010 (139 pages)

- BMK 1.5 LN Dual Fuel Jan 2009 (126 pages)

- BMK 1500-2000 (188 pages)

- BMK 1500DF (196 pages)

- C-More Control Panel (162 pages)

- BMK 2.0 LN October 2012 (172 pages)

- BMK 2.0 LN Natural Gas (SN G-11-1861 and above) (170 pages)

- BMK 2.0 LN Nat. Gas June 2010 (125 pages)

- BMK 2.0 LN Natural Gas 2008 (111 pages)

- BMK 2.0 LN Nat. Gas for Mass. only (113 pages)

- BMK 2.0 LN Dual Fuel Serial G-11-2402 and UP (160 pages)

- BMK 2.0 LN Dual Fuel Nov 2010 (139 pages)

- BMK 2.0 LN Nat. Gas (112 pages)

- BMK 2.0 LN for Mass. only (114 pages)

- BMK 3.0 LN Dual-Fuel Series Gas Fired Low NOx Boiler System (136 pages)

- BMK 3.0 LN Natural Gas July 2011 (129 pages)

- BMK 3.0 LN Nat. Gas Jan 2011 (129 pages)