10 air filter cleaning & replacement – AERCO BMK 6000 User Manual

Page 109

Benchmark 6000 Boiler Installation, Operation & Maintenance Manual

CHAPTER 7 – MAINTENANCE

OMM-0086_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 109 of 210

GF-133

Ph.: 800-526-0288

03/20/14

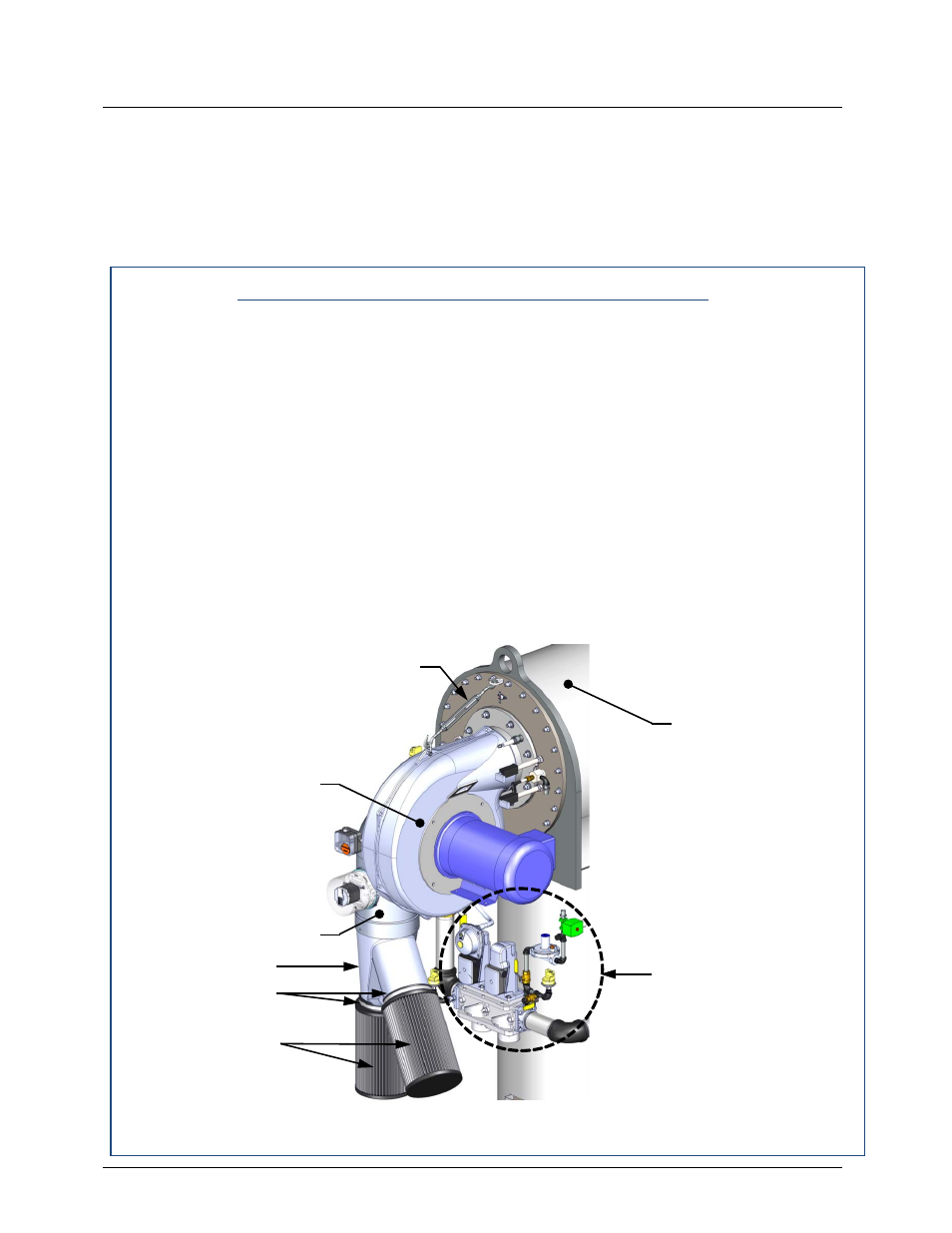

7.10 AIR FILTER CLEANING & REPLACEMENT

The Benchmark boiler is equipped with two (2) air filters (part no. 88014) which should be

cleaned and re-oiled every 12 months, or as needed if combustion air is dirty, and replaced every

24 months. The air filters are attached to a “Y” shaped duct connected to the inlet of the air fuel

valve as shown in Figure 7-11. To inspect/replace each air filter, proceed as follows:

Air Filter Cleaning & Replacement Procedures

1. Set the ON/OFF switch on the control panel, to the OFF position. Disconnect AC power

from the unit.

2. Remove the front panel from the unit by grasping the handles and pulling outward.

3. Refer to Figure 7-11 and locate the air filters attached to the “Y” shaped duct connected to

the air/fuel valve inlet.

4. Using a flat-tip screwdriver or 5/16” nut driver, loosen the clamp securing the filter to the

“Y” duct at the air/fuel valve inlet. Remove the filter and clamp.

5. The filters may be cleaned in hot soapy water to remove oil and dirt. The filter should be

thoroughly dried and then sprayed with a light coating of oil, (NOT WD-40), prior to

reinstallation.

6. Each replacement air filter is equipped with its own clamp. Therefore, simply install the

replacement air filter on “Y” duct and tighten the clamp with a flat-tip screwdriver or 5/16”

nut driver.

7. Replace the front panel on the unit and return boiler to service use.

Figure 7-11: Air Filter Location and Removal

AIR FILTERS

GAS TRAIN

AIR/FUEL VALVE

“Y” DUCT

BURNER ASSEMBLY

TURN-BUCKLE

BLOWER

AIR FILTER CLAMPS