AERCO BMK 1500-2000 User Manual

Page 127

Benchmark 1500 - 2000 Boilers

CHAPTER 10. BOILER SEQUENCING TECHNOLOGY

OMM-0097_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 127 of 188

GF-142

Ph.: 800-526-0288

10.3.7 Option 7 - Remote Setpoint with MODBUS Header Sensor AND 4-20ma

Setpoint Drive

NOTE: Both Header Sensor AND 4-20ma Direct Drive must be wired. See the C-More Controller User

Manual, OMM-0032, GF-112 and ProtoNode User Manual, OMM-0080, GF-129 for more information.

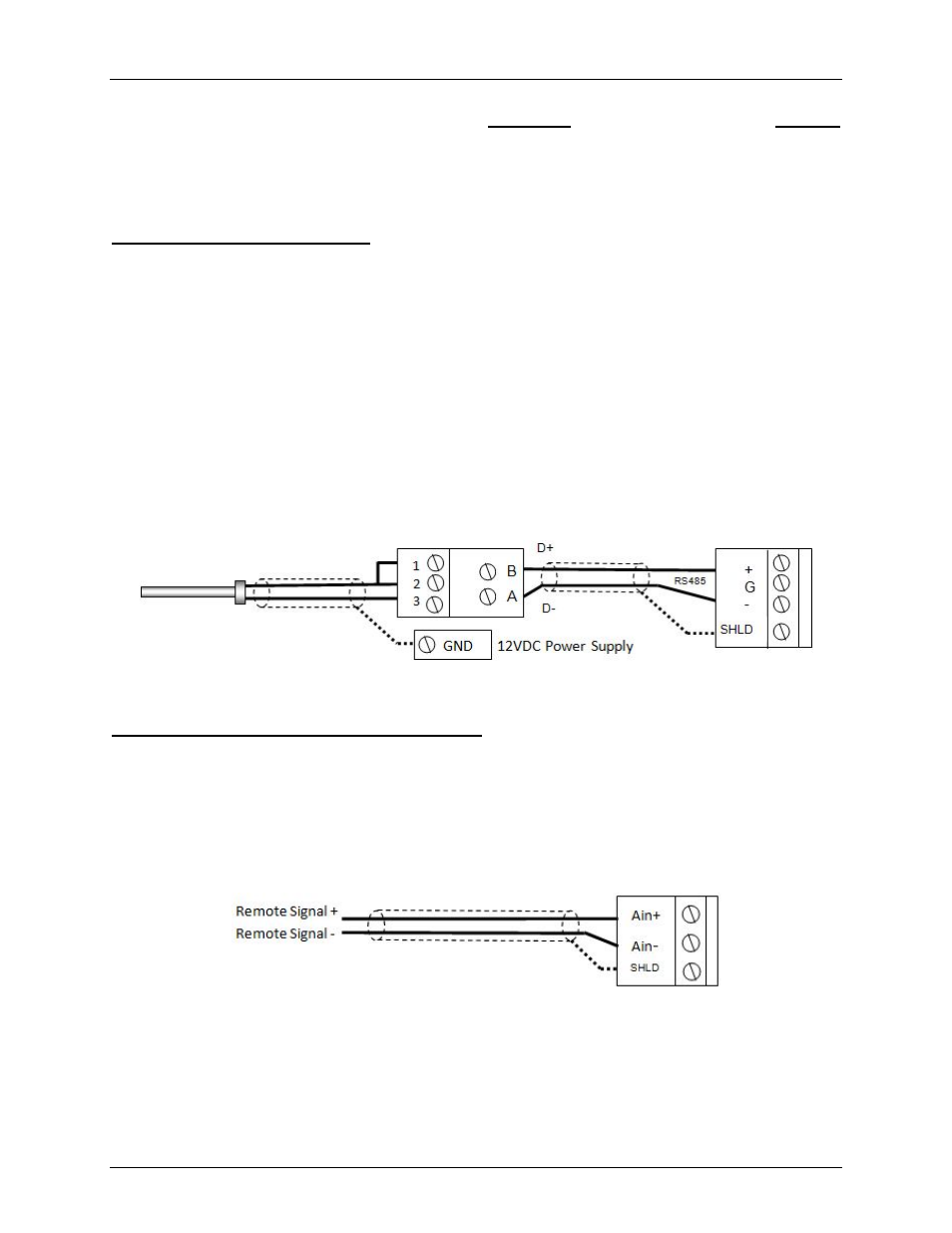

Step 1: MODbus Header Sensor

1. Using Shielded pair 18 - 22 AWG cable, Connect the Temperature Transmitter (AERCO P/N 65169)

terminal Pin B to the RS485+ terminal on the I/O Box of any of the Boiler units, and Pin A of the

Temperature Transmitter to the RS485- terminal on the I/O Box of any of the Boiler units.

2. Using Shielded pair 18 - 22 AWG cable, connect the Modbus Header Temperature Sensor (AERCO

PN 24410) to pins 2 and 3 of the Temperature Transmitter.

3. Install a jumper wire between pins 1 and 2 of the Temperature Transmitter.

NOTES:

• Polarity must be observed for the RS485 connections. The ground for the shield is at the “SHLD”

terminal in the I/O the Box.

• The header sensor must be installed between 2 and 10 feet downstream of the LAST boiler in the

plant’s supply water header.

• There is no polarity to be observed. The ground for the shield is at the power supply ground. The

sensor end of the shield must be left free and ungrounded.

Step 2: Direct Wired 0-20ma or 4-20ma Wiring

1. Connect the 4-20ma or 0-20ma terminals from the Direct Drive source to the Ain+ and Ain- terminals

on the Master.

NOTES:

• Unit’s I/O Box. Shielded pair 18 - 22 AWG cable is recommended for this connection. Polarity must

be observed.

• The ground for the shield is at the driver signal source.

Temp Sensor PN 24410 Modbus Transmitter

I/O Box

I/O Box