Lv-s31, Adjusting the trimmer (detection position), Adjusting the detection center – KEYENCE LV-N10 Series User Manual

Page 4: Lv-s41/s41l, Lv-s62, L-mounting bracket (optional: op-84350), Back surface mounting bracket (optional: op-84349), Horizontal mounting bracket (optional:op-84351), Lv-s71/s72

4

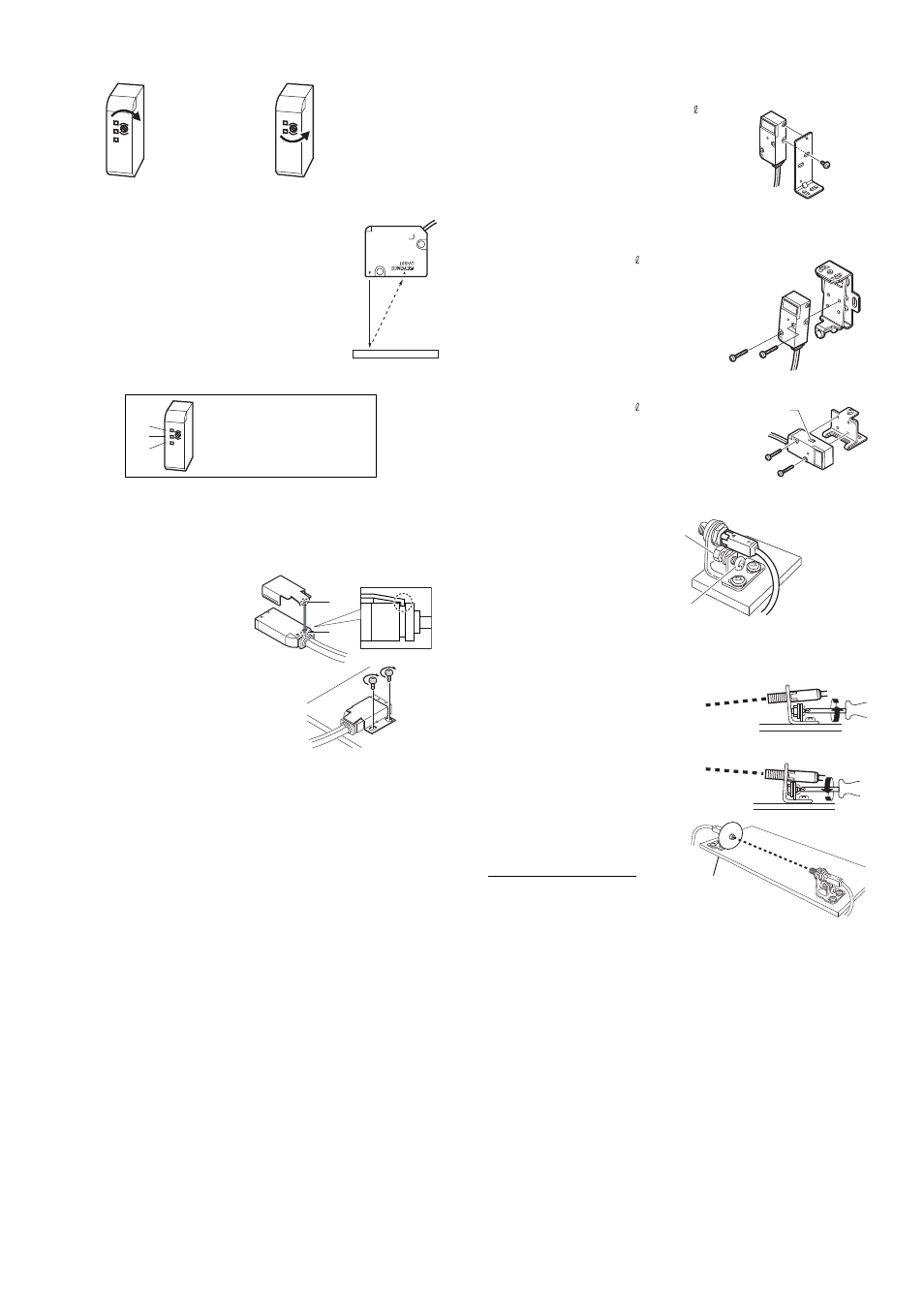

LV-S31

Adjusting the trimmer (detection position)

The detection range can be selected freely by adjusting the trimmer.

Adjusting the detection center

1

Place a workpiece at the position to be set as the detection

center.

2

Turn the trimmer and adjust so that the (2) JUST (center) indicator lights in green.

To set in further detail, adjust while monitoring the amplifier display. (Page 7)

LV-S41/S41L

Always use the included mounting bracket.

1

Attach the mounting bracket as

shown on the right.

Match section A of the bracket onto

section B of the sensor head.

2

Attach onto a flat surface with M3

screws as shown on the right.

(M3 screws are not included.)

LV-S62

Mount with the optional L-mounting bracket (OP-84350), back surface mounting bracket (OP-

84349) or horizontal mounting bracket (OP-84351).

L-mounting bracket (optional: OP-84350)

Included: Mounting bracket

1 / plate nut

1 / M3

7.3

screw

1

Back surface mounting bracket (optional: OP-84349)

Included: Mounting bracket

1 / M3

18

screw

2

Horizontal mounting bracket (optional:OP-84351)

Included: Mounting bracket

1 / M3

18

screw

2

LV-S71/S72

1

Attach so that the side on

which the T (transmitter) and

R (receiver) are printed faces

upward. The operation indica-

tor lights are on the printed

side.

2

Adjust the beam axis.

The beam axis can be adjusted in the downward

direction by tightening the screw as shown with the

arrow. It can be adjusted in the upward direction by

loosening the same screw.

Adjust so that the beam spot is centered on the

receiver.

When adjusting, attach the beam axis alignment

plate included with the sensor head onto the end

of the receiver side to aid in alignment.

Remove the beam axis alignment plate when fin-

ished adjusting.

F

J

N

F

N

F

J

N

F

N

To detect from a long

distance, turn the

trimmer clockwise

and adjust.

To detect from a short

distance, turn the

trimmer counterclock-

wise and adjust.

F

J

N

F

N

If (1) is ON, turn the trimmer clockwise until

(2) turns ON.

If (2) is ON, adjustment is finished.

If (3) is ON, turn the trimmer counterclock-

wise until (2) turns ON.

(1)

(2)

(3)

A

B

Spot selection

switch

Fixing nut

Axis beam adjustment

screw

The tightening torque

is 1.2N·m or less.

To move the beam axis downward

To move the beam axis upward

Beam axis

alignment plate