Maintenance – FRITSCH PULVERISETTE 19 User Manual

Page 48

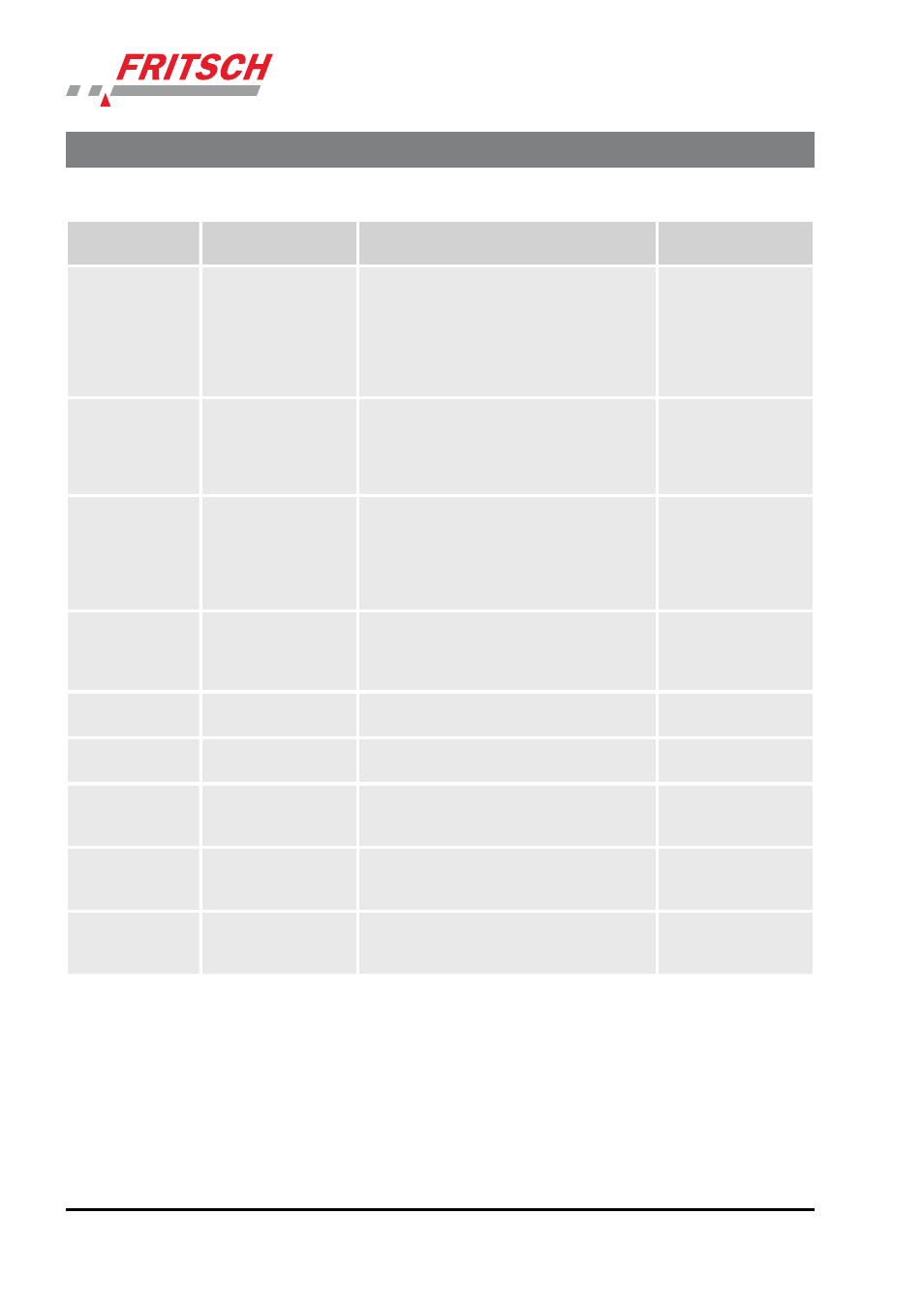

Function / Func-

tional part

Task

Test

Maintenance interval

Exhaust filter (25)

Filtering exhaust air

Clean exhaust filter (25). To do this, lever out

the filter holder (A) with a screwdriver or

similar. Beat the filter foam mat (B). Clean

using compressed air or dust exhaust system.

Replace the filter foam mat (B) if it is very

heavily soiled. Article number: 90.0740.16

filter foam mat.

Before every commi-

nution

Safety lock (11)

Locking the closing lid

(6)

Is the closing lid (6) locked when control

switch (19) is set to 0? If NOT à safety lock

(11) defective. Disconnect the device from

the mains immediately. Replace the safety

lock (11).

Before each use

Safety switch (15)

Protecting the lower

opening of the cutting

chamber

Is the cutting mill running without the col-

lecting vessel (8) or the adapter for exhaust

system (27)? If YES à safety switch (15)

defective. Disconnect the device from the

mains immediately. Replace the safety

switch (15).

Before each use

START button

Indicating readiness

for operation

Does the START button light up green if the

control switch (19) is set to AUTO or HAND?

If not, see Ä Chapter 11 ‘Guarantee terms’

Before each use

Rotor (3)

Comminuting material Is the rotor (3) sharp? Maintenance:

resharpen

Before each use

Fixed knives (4, 5,

9)

Comminuting material Are the fixed knives (4, 5, 9) sharp? Check

visually! Maintenance: resharpen

Before each use

Cutting gap

Cutting procedure

Measure gap width. For setting see

Chapter 6.1.3 ‘Setting the gap width of the

Whenever rotor and

fixed knives are

changed

Cones

Centring rotor (3)

Check cones for cleanliness and grooves. See

Chapter 6.1.4 ‘Inserting / changing a rotor’

Whenever rotor is

changed

Filter, sieve and

sample exhaust

system

Filtering exhaust air

Vortex of comminution material in the collec-

tion bottle slows down! For cleaning see

Chapter 7 ‘Cleaning’ on page 42!

Before each use

Maintenance

- 48 -