4 inserting / changing a rotor, Using the device – FRITSCH PULVERISETTE 19 User Manual

Page 31

4.

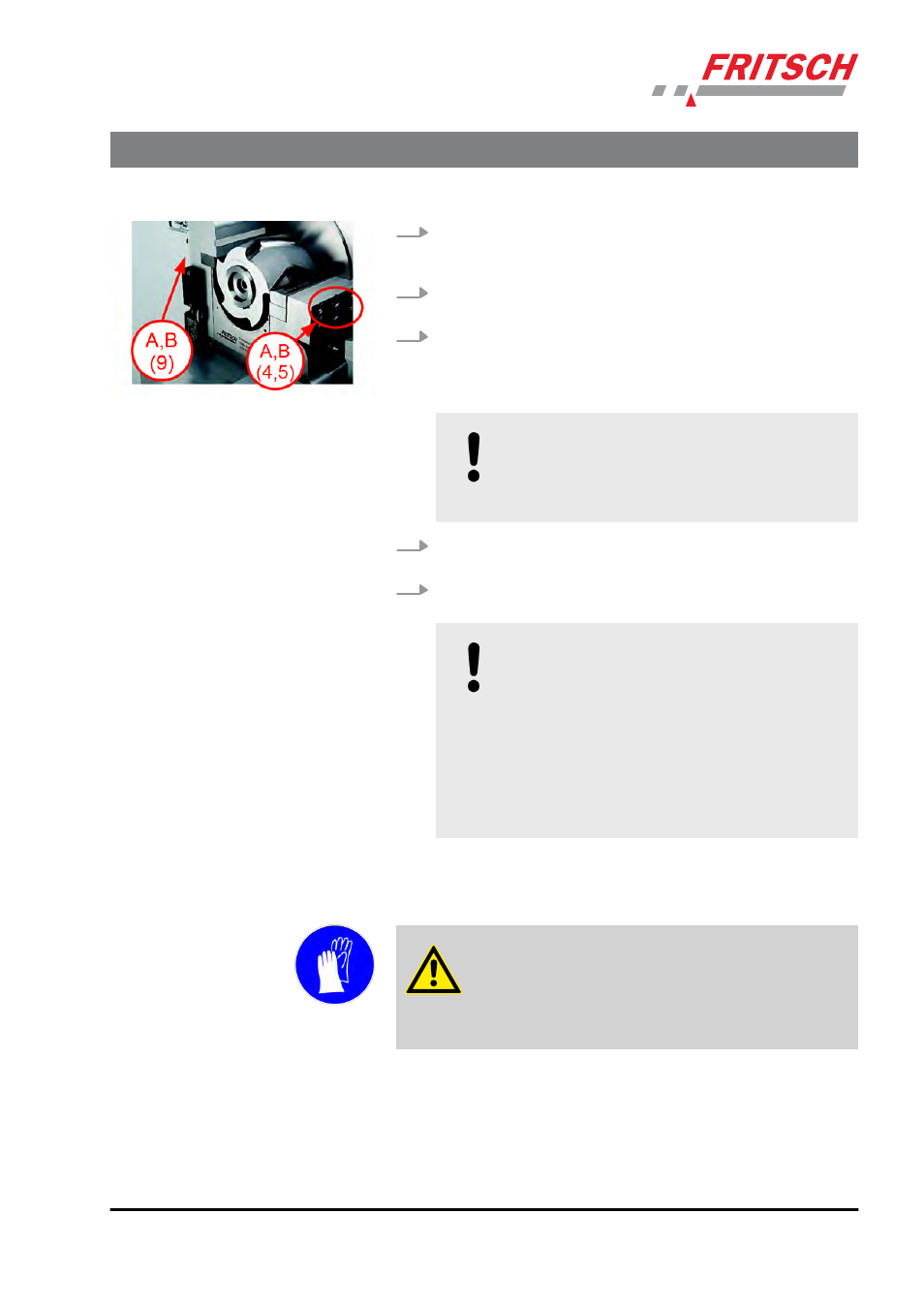

Screw in the right and left threaded pins (B) beside the retaining

screw (A) equally until the fixed knives (4, 5, 9) come up against

the rotor knives.

5.

Then turn the threaded pins (B) evenly back by ¼ of a turn and

retighten the retaining screw (A).

6.

Set all 3 fixed knives (4, 5, 9) in this way.

A knife gap of approx. 0.2 mm is then set using this method. This

can be checked using a feeler gauge. (0.2 mm, approx. 2 sheets of

printing paper, DIN A4 80 g)

NOTICE!

The fixed knives (4, 5, 9) must run parallel to the

rotor knives so that the cutting load is distributed

evenly across the whole length.

7.

Insert the sieve cassette (7) (see Ä Chapter 6.1.5 ‘Inserting /

changing a sieve cassette’ on page 33).

8.

Close the cutting mill (see Ä Chapter 6.1.6 ‘Closing the cutting

NOTICE!

Check if the rotor (3) is turning freely (see

Chapter 6.1.7 ‘Checking if the rotor is turning

freely’ on page 34).

If this is not the case, proceed as described in

Chapter 6.1.3 ‘Setting the gap width of the knives’

on page 30.

This check must also be carried out every time the

rotor (3) is changed!

6.1.4 Inserting / changing a rotor

CAUTION!

Risk of injury!

Beware of the sharp edges of the rotor!

Wear safety gloves when changing the rotor!

A, B (9)

Retaining screw (A) and

threaded pins (B) for fixed

knife (9)

A, B (4,

5)

Retaining screws (A) and

threaded pins (B) for fixed

knife (4, 5)

Using the device

- 31 -