4 filling quantities of grinding bowls, 5 filling the grinding bowl, Using the device – FRITSCH PULVERISETTE 7 premium line User Manual

Page 36

The large surface of many small balls results in high thermal stress due to

the friction effect. It can already be measured after 5 minutes of grinding

above 100 °C by a surface sensor on the surface of the lid. Inside the

grinding bowl, the temperature is then much higher.

The adhesive used is permanently resistant to temperatures

of up to 140 °C. If the external temperature does not exceed

100 °C, the adhesive will hold.

5.4 Filling quantities of grinding bowls

Grinding bowl

Min. sample quantity Max. sample quantity

20 ml

1 ml

9 ml

45 ml

3 ml

20 ml

80 ml

10 ml

30 ml

CAUTION!

For wet grinding with large balls with a diameter of >

10mm, at least half the maximum sample quantity must be

inserted. If the suspension is highly fluid, the balls will not

have any resistance and the balls and the grinding bowl

could be damaged. The result is the same as if no material

to be ground were filled. The same applies to dry grinding

with less than the minimum sample quantity.

NOTICE!

If the minimum filling quantity is fallen short of, increased

wear due to abrasion is to be expected. This can cause

irreparable damage to the mill components.

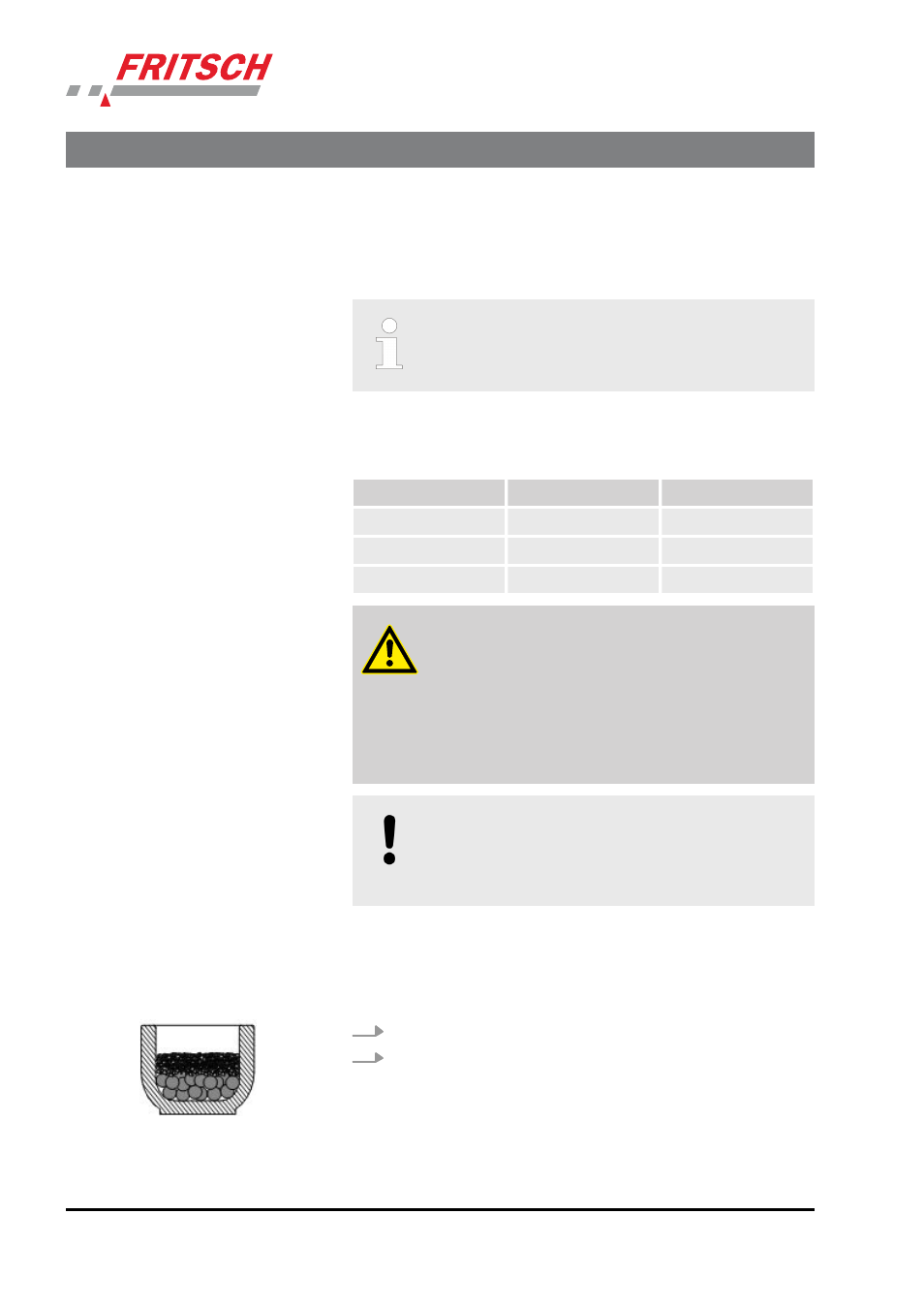

5.5 Filling the grinding bowl

Do not fail to comply with the following sequence:

1.

Place the grinding balls in the empty bowl.

2.

Fill material to be ground over the balls.

Using the device

- 36 -