Appendix c - calibration procedures – Brookfield YR-1 Rheometer User Manual

Page 46

Brookfield Engineering Labs., Inc.

Page 46

Manual No. M02-215-B0412

APPENDIX C - Calibration Procedures

For more help you can go to the website,

www.brookfieldengineering.com, and download the video.

The torque sensing spiral spring in the YR-1 Rheometer is calibrated at Brookfield to be accu-

rate within ±1% of full scale range of a certified master viscometer. However, when checking

calibration with a vane spindle using the following procedures, an accuracy of ±2% of full scale

range is allowed.

The accuracy of the YR-1 is verified using one of your vane spindles with the appropriate viscos-

ity standard fluids which are available from Brookfield Engineering Laboratories or your local

Brookfield agent. Viscosity standards are Newtonian and, therefore, have the same viscosity

regardless of spindle speed. Viscosity standards, calibrated at 25°C, are shown in Table C-1

(Silicone Oils) and Table C-2 (Mineral Oils).

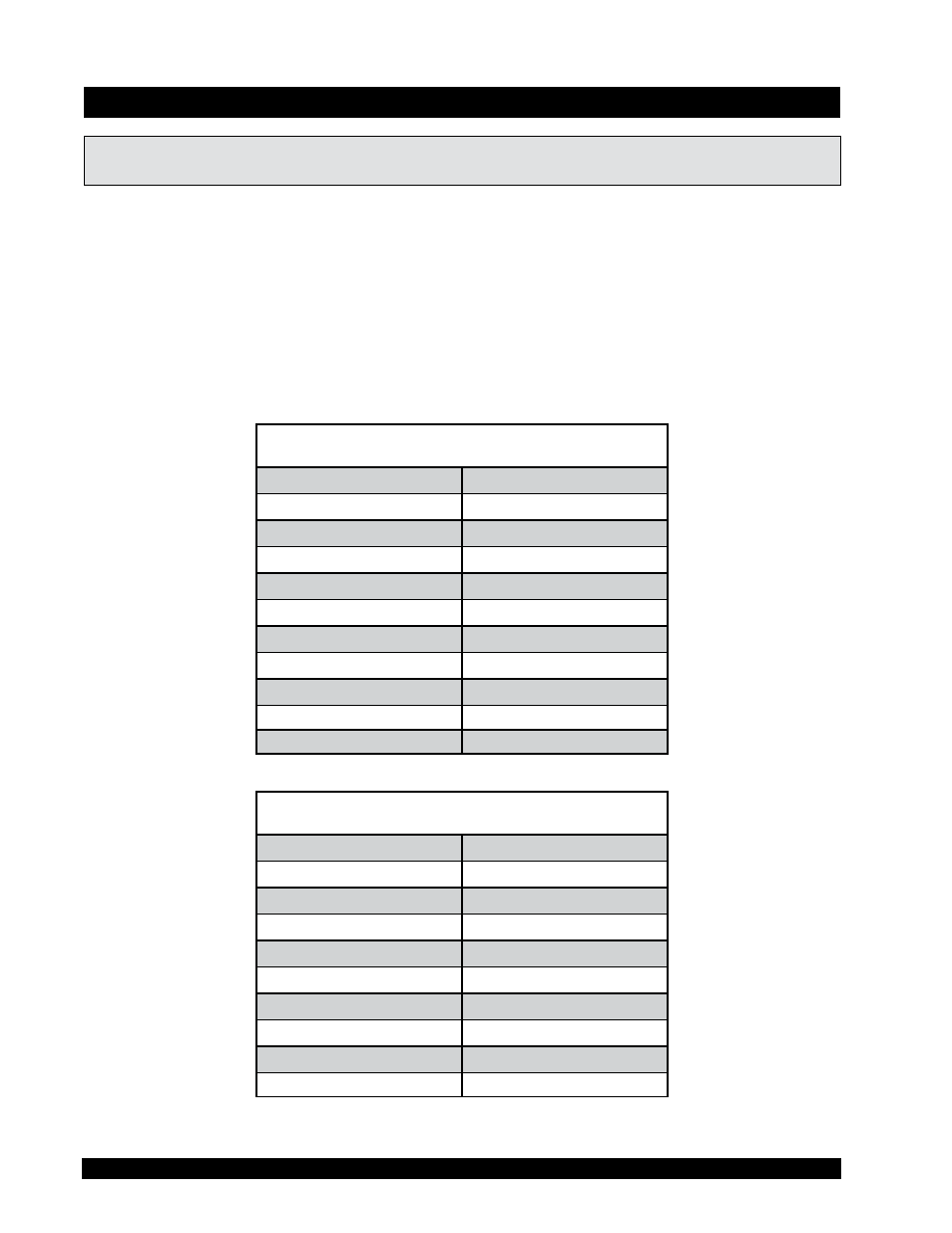

GENERAL PURPOSE SILICONE FLUIDS

BEL Part No.

Viscosity (cP) 25ºC

5 CPS

5

10 CPS

10

50 CPS

50

100 CPS

100

500 CPS

500

1,000 CPS

1,000

5,000 CPS

5,000

12,500 CPS

12,500

30,000 CPS

30,000

60,000 CPS

60,000

100,000 CPS

100,000

Table C-1 - Silicone Viscosity Standard Fluids

MINERAL OIL VISCOSITY STANDARD FLUIDS

BEL Part No.

Viscosity (cP) 25ºC

B29

29

B200

200

B600

600

B1060

1,060

B2000

2,000

B10200

10,200

B21000

21,000

B730000

73,000

B200000

200,000

B360000

360,000

Table C-2 - Mineral Oil Viscosity Standard fluids