Park Tool AK-38 User Manual

Ak-38 advanced mechanic tool kit, English pg-1

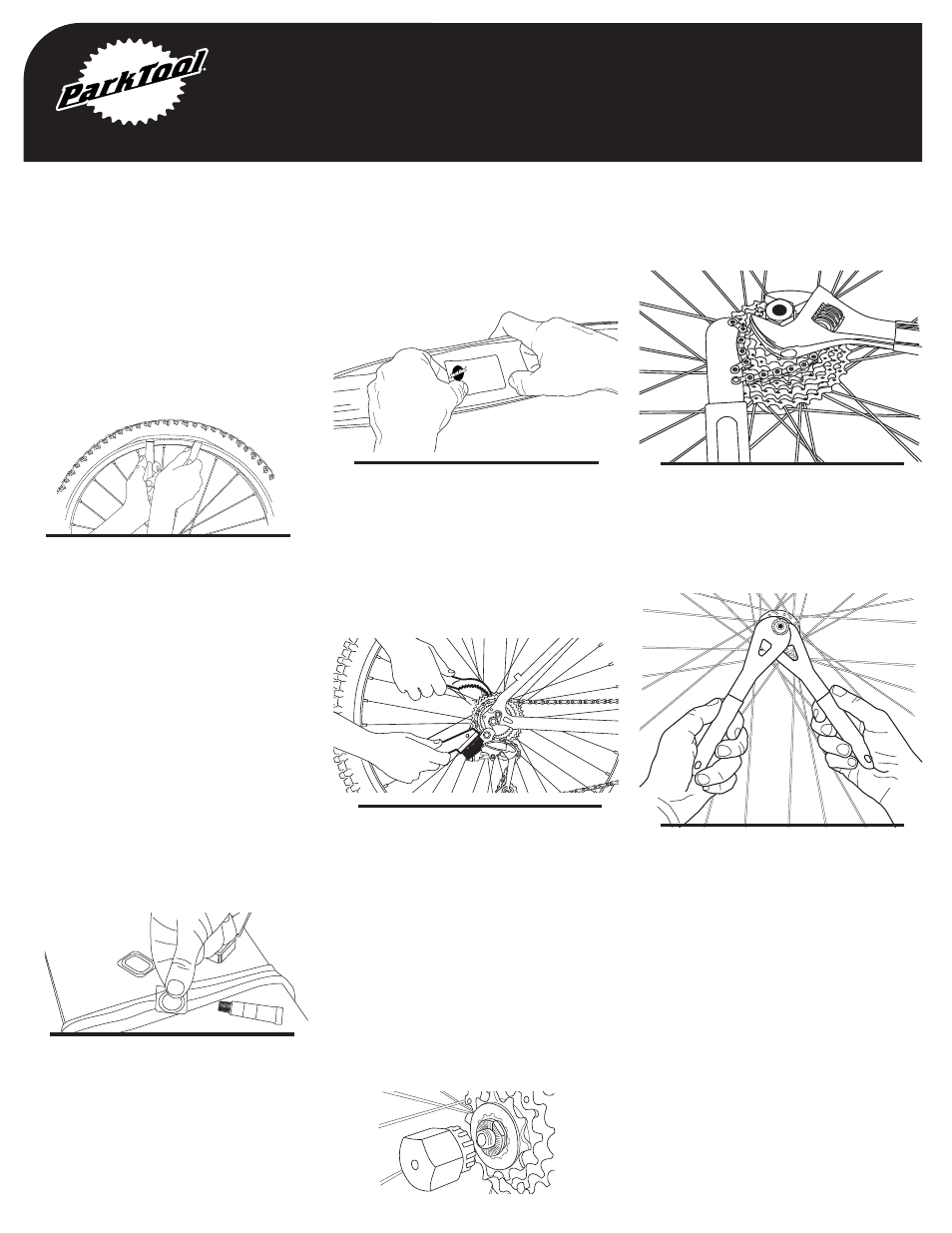

FR-5 Cassette Lockring Tool

A cassette lockring tool is used to remove and

install the cassette lockring and cogs on the rear

wheel. The FR-5 fits Shimano, SRAM, SunRace,

and other 12-tooth cassette lockrings.

Instructions:

Lockring Removal: Fit cassette lockring tool

into splines of lockring and install quick release

skewer to prevent tool from slipping. Hold

cassette cogs with chain whip (Park Tool SR-11)

and turn cassette lockring tool counterclockwise

with adjustable wrench until lockring is removed.

Lockring Installation: Fit cassette lockring tool

into splines of lockring and turn clockwise with

wrench until tight.

Instructions:

Locate cut or tear then clean and dry surrounding

surface to promote adhesion of boot. Peel

the protective backing from TB-2 and apply,

allowing TB-2 to adequately overlap damaged

area. Note: The TB-2 is designed for emergency

use. A patched tire should be replaced as soon

as possible.

GSC-1 GearClean Brush

The GSC-1 is specially designed to remove dirt,

grit, and grime from the sprockets on the rear

wheel. Just insert the curved end of the GSC-

1 between the gears and pedal backwards.

Then use the brush end to remove the loosened

dirt and grit. Also works great for cleaning

derailleurs, brakes and anywhere grease and

dirt collect.

SR-11 Chain Whip

The SR-11 is used when removing cassette cogs

from the rear wheel. It firmly holds the cassette

cogs so a cassette lockring tool can be used to

remove the cassette lockring.

TL-6 Tire Levers

Tire levers are designed to remove and install

tires from the rim of a wheel. TL-6 Tire Levers

have a steel core that is covered with a special

composite material to prevent scratching

of carbon fiber, anodized and painted rims.

Instructions:

Deflate tire completely. Push bead of tire from

edge of rim. Insert tip of one lever under bead.

Insert tip of second lever under bead 8 - 10 cm

from first lever. Push down on both levers to pry

up bead. Slide second lever along rim until bead

is completely removed. Remove second tire bead

from rim to completely remove tire and tube.

TB-2

Emergency T

ire Boot

SCW Shop Cone Wrenches

(13mm to 19mm)

Park Tool Shop Cone Wrenches are designed to

fit the narrow wrench flats on hub adjustment

cones and locknuts when disassembling, as-

sembling, and adjusting wheel hubs.

SW-0 and SW-2

Professional Spoke Wrenches

A wheel occasionally needs to be straightened

or “trued” in order to keep the rim running

straight as it passes between the brake pads.

A spoke wrench is required for tightening and

loosening spoke nipples when truing a wheel.

SW-0 (Black): .127 (3.23mm)

SW-2 (Red): .136 (3.45mm)

Instructions:

Detailed instructions for truing wheels can

be found in a number of books, as well as

on-line at www.parktool.com. Below are

instructions for basic lateral truing, which

can easily be performed with the wheel in

the bike (more advanced truing requires the

wheel to be removed from the bike and trued

in a truing stand, such as the Park Tool TS-2.2

or TS-8).

TB-2 Emergency Tire Boot

Designed to get you back on the road or trail, the

TB-2 Tire Boot quickly and easily installs to patch

cuts, scrapes, and tears in any size tire. The thin,

reinforced tire boot film adheres to the inside of

the tire and prevents the tube from protruding

out of the cut or tear.

© 2013 Park Tool Co.

® PARK TOOL and the color BLUE are registered trademarks of Park Tool Co. All other referenced trademarks and trademark registrations are the property of their respective owners.

English pg-1

VP-1 Vulcanizing Patch Kit

Glass, thorns, nails, and other debris can punc-

ture a wheel’s inner tube, which holds air inside

the tire. The VP-1 Patch Kit is used to patch small

holes so the punctured tube can be reused.

Patching Inner Tubes

1. Remove tire and tube from wheel using

tire levers.

2. Re-inflate inner tube until double in size.

3. Inspect inner tube for leaks.

4. Lightly buff area around hole with sandpa-

per and wipe away dust. Deflate tube.

5. Apply a thin coat of vulcanizing fluid and

spread evenly around area of hole. Allow

fluid to dry.

6. Peel protective backing from patch (leave

clear film on patch), center patch to hole,

and press firmly onto tube.

7. Place tube inside tire, install tire on wheel,

and pump to pressure recommended on tire.

Park Tool Co.

5115 Hadley Ave. N. St. Paul, MN 55128 (USA) www.parktool.com

AK-38 Advanced

Mechanic Tool Kit

• For detailed instructions on a variety of maintenance and repair

procedures: www.parktool.com

• Für detallierte Informationen und Reparatur Tipps: www.parktool.com

• Pour des informations plus complètes sur toute une multitude de tâches

d’entretien ou de réparation contactez : www.parktool.com

• Para instrucciones mas detalladas en una variedad de mantenimientos

y procedimientos de una reparación: www.parktool.com