Simulated testing – Rice Lake BCi Belt Scale - Installation and Operation Manual Version 2.03 User Manual

Page 59

Installation & Operation Manual - Calibration

53

Simulated Testing

A simulated load test consisting of at least three consecutive test runs should be conducted as soon as possible,

but not more than 12 hours after the completion of the material test, to establish the factor to relate the results of

the simulated load test to the results of the material tests. The results of the simulated load test should repeat

within 0.1 percent.

Simulated testing is used only with auto calibration of the integrator.

There are two different simulated load testing techniques that can be used. They are:

•

Roller test chains

•

Static test weights

There are several advantages and disadvantages to each of the list simulated testing techniques. They are listed

below.

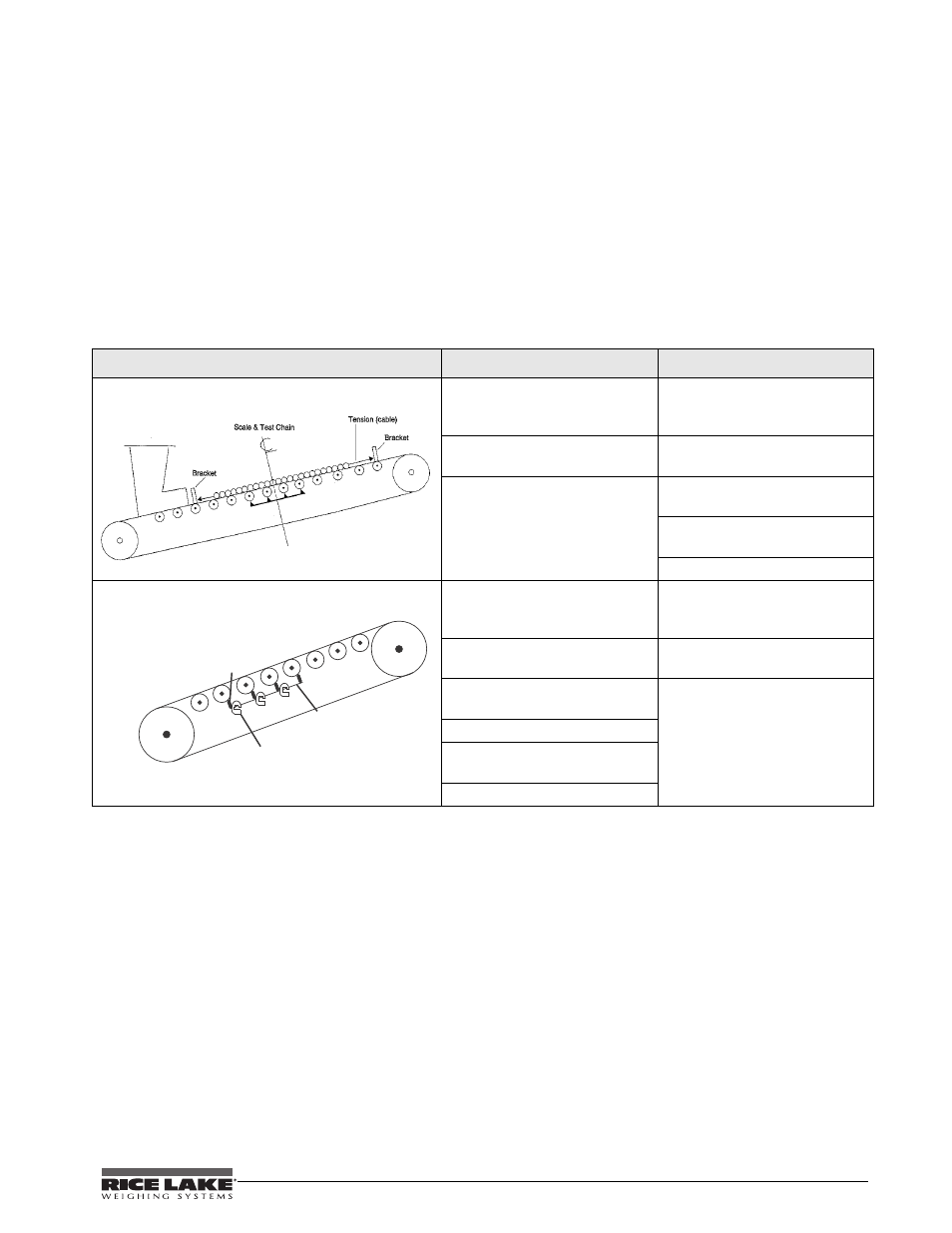

Table 5-2. Advantages and Disadvantages to Simulated Testing

Simulated Testing Type

Advantages

Disadvantages

Roller (chain)

Simulates some conveyor belt

effects

Chains do not provide a traceable

conveyor scale calibration

standard.

Acceptable simulated test

Heavy chains are difficult to

handle.

Conveyor belt must be stopped

to apply and remove.

Linearity test requires several

chains.

Chains are costly.

Static

Test Weights (3)

Belt Scale

Test Weight Brackets

Simulates some conveyor belt

effects

Weights do not provide a

traceable conveyor scale

calibration standard

Easy to apply

Does not simulate conveyor belt

effects

Conveyor belt does not have to

be stopped to apply

Linearity test is easy to perform

Detect load cell failures, and

applies force to the load cell

Acceptable simulated test