3 belt travel speed wheel - optional, 4 magnetic shaft encoder - optional, Belt travel speed wheel - optional – Rice Lake BCi Belt Scale - Installation and Operation Manual Version 2.03 User Manual

Page 12: Magnetic shaft encoder - optional

6

Installation and Operation Manual

1.1.3

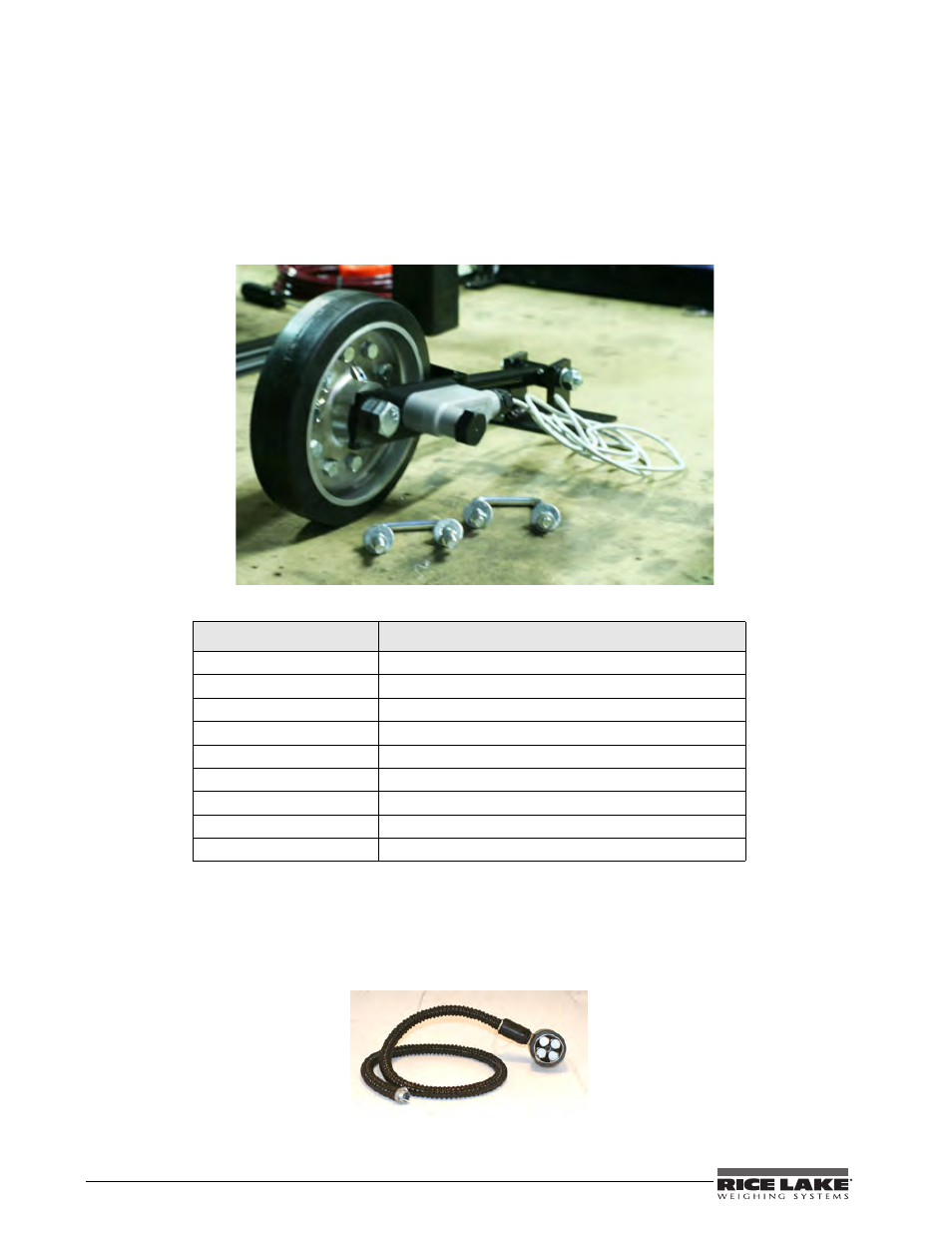

Belt Travel Speed Wheel - Optional

The belt travel speed wheel is located near the weigh frame. Positive contact must be maintained between the roll

and the belt for proper operation. The speed sensor should never come in contact with material that is being

conveyed along the belt. The signal generated by the speed wheel is converted by the integrator into a value that

represents belt travel distance. Various devices used for sensing belt travel include AC and DC generators,

mechanical belt or chain drives, photo-optical segmented disks, and electromagnetic pulse generators.

Installation procedures for the speed wheel are explained in detail on page 23. Figure 1-4 illustrates the major

component parts of the speed wheel.

Figure 1-4. Speed Wheel

Table 1-2. Speed Wheel Assembly Component Part Numbers

RLWS Part Number

Description (Quantity)

94969

Complete Speed Wheel Assembly (1)

96543

Speed Wheel (1) (wheel only)

94979

Speed Proximity Sensor (1)

94970

Speed Wheel Bracket Assembly (1) (wheel not included)

Cabling to integrator (1)

94980

U-Bolts (2)

21161

Splice Box (1)

98501

Expansion Cable - 20’

100038

Magnetic Shaft Encoder

1.1.4

Magnetic Shaft Encoder - Optional

Another option besides the belt travel speed wheel is a magnetic shaft encoder which can also be used to

determine belt travel distance like the speed wheel. The magnetic shaft encoder should never come in contact

with material that is being conveyed along the belt nor the belt itself. The signal generated by the encoder is

converted by the integrator into a value that represents belt travel distance.

Figure 1-5. Magnetic Shaft Encoder