0 calibration, 1 speed sensor calibration, Calibration – Rice Lake BCi Belt Scale - Installation and Operation Manual Version 2.03 User Manual

Page 54

48

Installation & Operation Manual

5.0

Calibration

There are two components of the Belt Scale Conveyor system that need to be calibrated for the system to work.

Those component parts include:

•

Speed sensor

•

Integrator (BCi)

Note

The speed sensor calibration must be done prior to the integrator calibration.

5.1

Speed Sensor Calibration

A belt conveyor scale shall be equipped with a belt speed or travel sensor that will accurately sense the belt speed

or travel whether the belt is empty or loaded.

Use the following steps to calibrate the speed sensor.

1. Select the

Belt Calibration

softkey from the Supervisors menu.

2. The integrator will change the softkeys to

Start

,

Stop

, and

Exit

.

3. A reference point needs to be marked on the conveyor belt and a reference needs to be marked on the

conveyor frame. This will give the operator a reference to count the number of revolutions the belt

travels during the speed calibration. The more revolutions in a test, the better the speed and distance

accuracy.

4. Press the

Start

softkey. This will cause the integrator to change screens displayed the number of pulses

counted, the frequency of the pulses and the time the test is running as shown below.

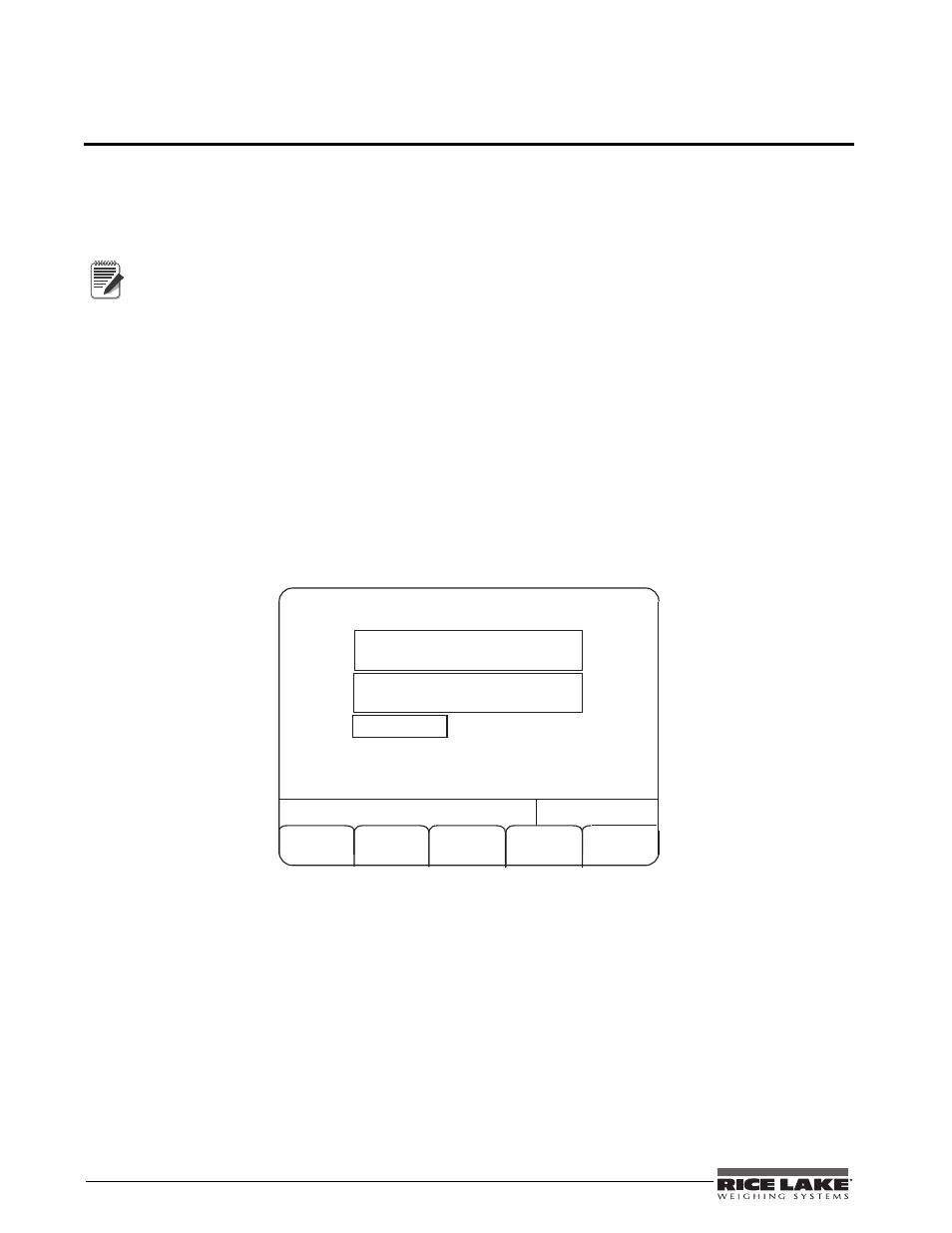

Exit =>

SCALE #1

Start

11/23/2011

08:13AM

96489 Pulse

261 Per Sec

889.25

Time Running

Stop

Figure 5-1. Pulses Counted

The screen illustrates a live display of how the belt is working. If the pulses and frequency are not

changing then there is a problem with the speed sensor and can be a sign that either the wiring or the

sensor itself is bad. During this cycle of the calibration procedure, the operator needs to count the

number of belt revolutions.

5. Pressing the

Stop

softkey will stop the speed sensor calibration. The integrator will then prompt the user

to enter the number of belt revolutions