23 span error, 24 zero counts, 25 zero error – Rice Lake BCi Belt Scale - Installation and Operation Manual Version 2.03 User Manual

Page 49: 26 idler spacing, 27 number of idlers, 28 belt test revolutions, 29 pulses per revolution, 30 belt length, 31 belt angle

Installation and Operation Manual - Supervisor Mode Parameters

43

An example of calculating the material factor is:

what you want

what you’ve got X 100 = Material Factor

4.23 Span Error%

this is the percentage of error calculated during the

span calibration. The relation between the calculated

span and the actual registered span.

4.24 Zero Counts

This parameter illustrates the raw dead load counts of

a calibrated system. This value can be recorded and

entered manually in the event of a complete integrator

replacement.

4.25 Zero Error%

This is the percentage of error calculated during the

zero calibration. This is a direct relation between

theoretical zero and actual zero with dead load on the

load cells.

4.26 Idler Spacing

This parameter defines the spacing between the idlers.

It also determines the weighing surface of the belt

scale.

Refer to Section 1.3.3 on page 9 to determine your

idler spacing. That number is the number that is

entered into the integrator Idler Spacing parameter.

If the unit of measure is in feet, this value is entered in

inches. If the unit of measure is in meters, this value is

entered in meters.

The default value of this parameter is: 48 inches.

4.27 Number of Idlers

This parameter defines the number of idlers in a

system.

Enter the number is idlers being used in the system

using the numeric keypad and press

enter

.

The default value for this parameter is: 1.

4.28 Belt Test Revolutions

This parameter defines the number of conveyor belt

revolutions the unit will make after the belt speed

calibration is done. The operator will key in the

number of full belt revolutions the unit will make for

the deadload and span calibrations. The deadload, or

zero calibration is a calibration that runs for a

pre-determined amount of time during which the belt

is running with no material on it. The span calibration

is a calibration that runs for the same pre-determined

amount of time with a known weight applied to the

scale.

The default value for this parameter is: 1.

4.29 Pulses per Revolution

This value is the number of pulses recorded for a

complete revolution of the belt. This value can be

recorded and entered manually in the event of a

complete integrator replacement.

The default value for this parameter is: 3600.

4.30 Belt Length

This is the total length of the conveyor belt. This value

can be recorded and entered manually in the event of a

complete integrator replacement. An easy way to

measure the belt length is to spray paint a marking on

the belt. Run a tape measure down to the other end

and times it by two to get the total belt length.

Enter the total belt length being used in this system

using the numeric keypad. Press the

enter

key to save

that value.

The default value for this parameter is: 600.

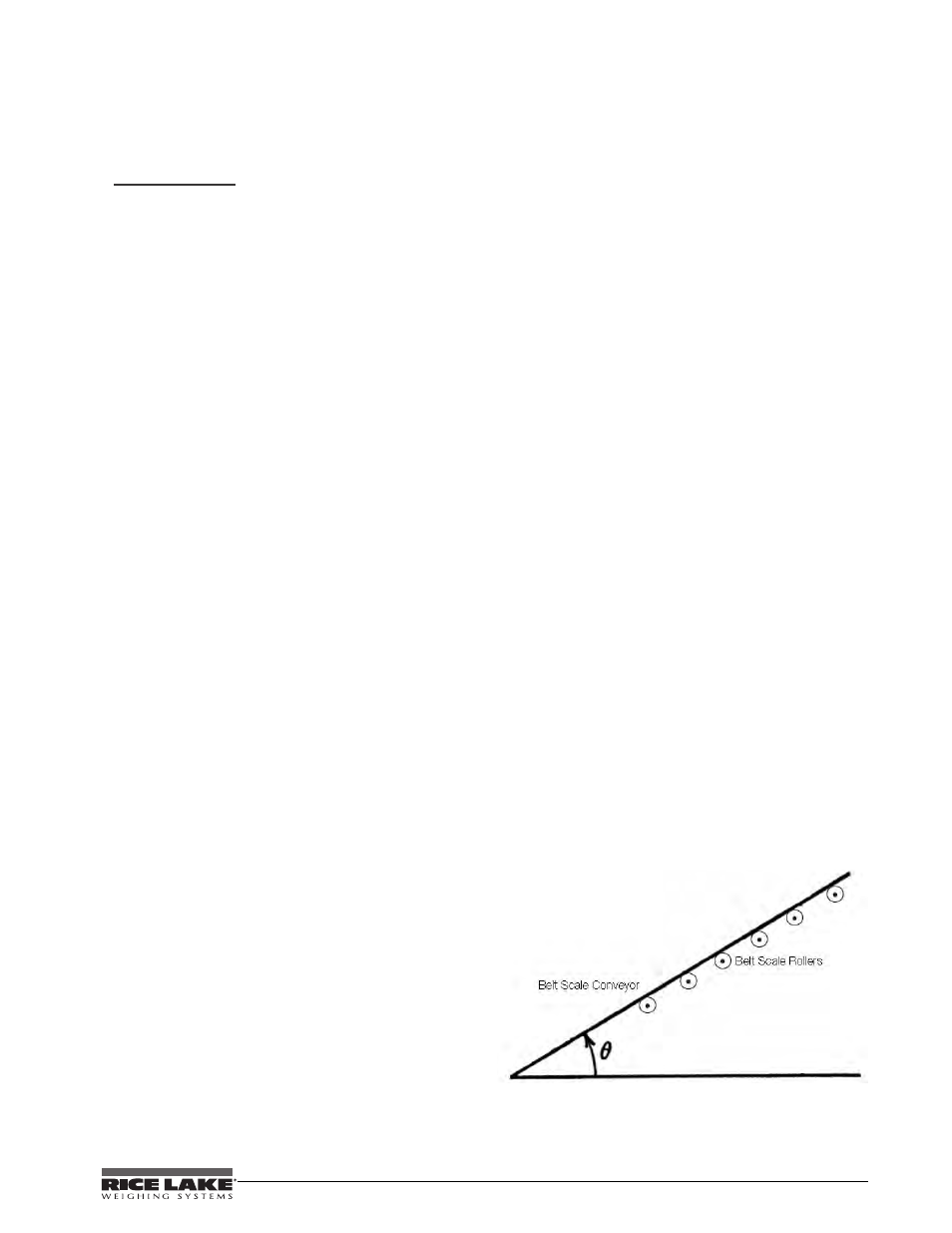

4.31 Belt Angle

This is the angle of the conveyor measured in degrees.

this should be used when using the BCi integrator

with weigh frames containing only one or two load

cells.