90-osc-assembly – Oldcastle BuildingEnvelope Reliance StormMax User Manual

Page 40

37

R E L I A N C E S T O R M M A X I N S T A L L A T I O N M A N U A L

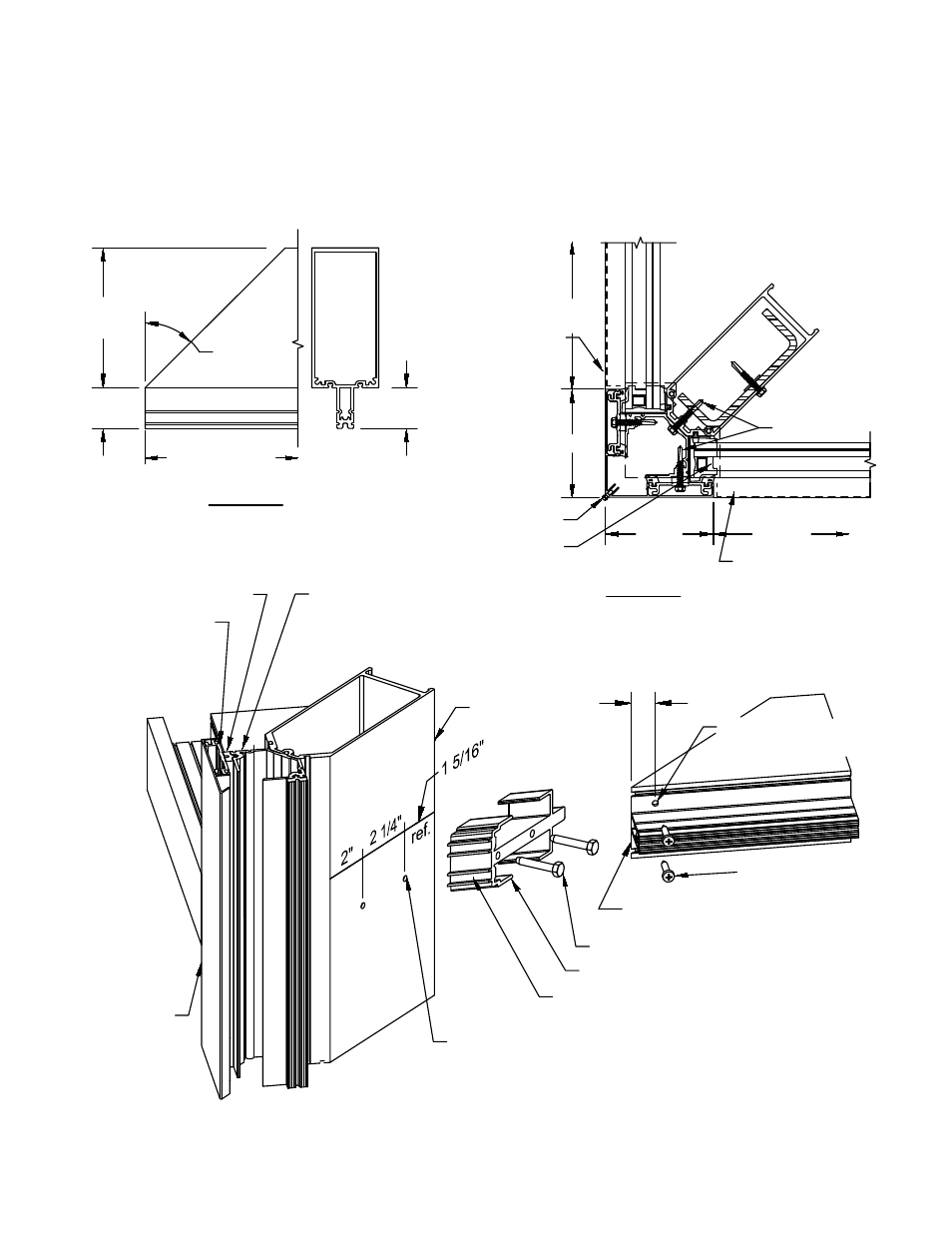

6.1 FIGURE 6.1 shows the basic layout of the standard one-piece corner mullion assemblies. These details

are for general reference and do not necessarily reflect all conditions. For specific assembly, sealing and

anchoring notes, refer to approved shop drawings.

HW-240

HW-180-01 shear block

FS-9 (2)

FS-118 (2)

Straight cut at glass pocket

(Refer to DETAIL "A")

1.50

45 degree

Detail "A"

Miter Cut at 1.50" Horizontal

HW-115

face cover

(continuous)

WW-162

pressure plate,

attach with

FS-325 at 9" O.C.

(continuous)

GP-107 isolator

(continuous)

HW-132

mullion adaptor, attach

with FS-325 at 9" O.C.

(continuous)

5.203

1.50 REF.

Cut length = D.L.O.

(see DETAIL "B")

4.00"

D.L.O.

4.00"

D.L.O.

Detail "B"

Captured OS 90 Corner

Assembly Guide

Match drill shear block with

5/32" dia. drill for #10 screw

FS-325

#11 (.191 dia.) tap hole for #14 fastener

#11 (.191 dia.) clear

hole for #10 fastener

WW-162

pressure plate

(D.L.O. minus 1/4")

WW-110 face cover

(D.L.O. minus 1/16")

FIGURE 6.1

Captured OS 90 Corner Assembly

(Cut lengths in parentheses)

3/4"

Work point

WW-352 zone plug

(typ. both sides)

OS 90 DEGREE CAPTURED CORNER ASSEMBLY