Mullion-fabrication – Oldcastle BuildingEnvelope Reliance StormMax User Manual

Page 10

7

R E L I A N C E S T O R M M A X I N S T A L L A T I O N M A N U A L

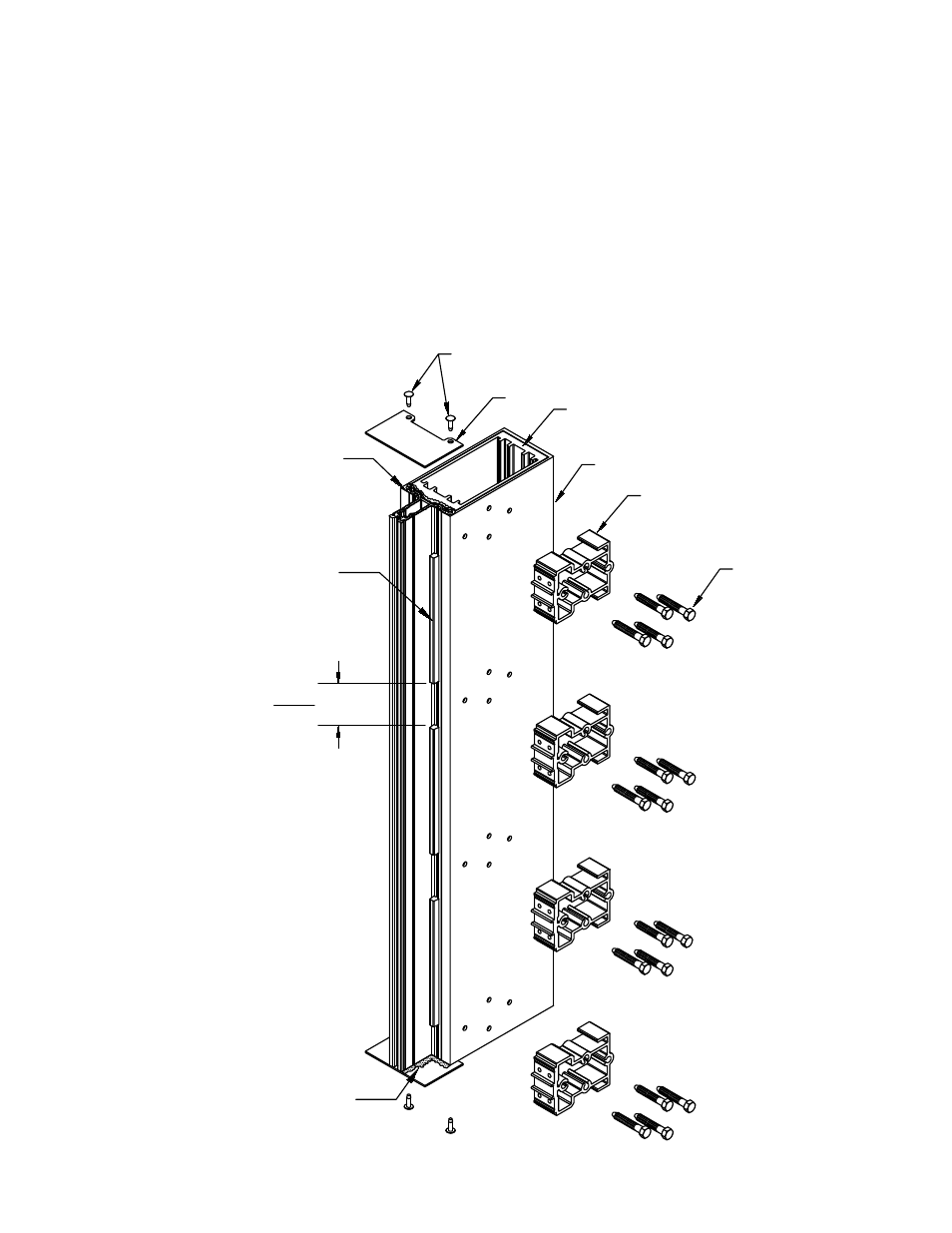

FIGURE 1.4

1.4 a. Prior to HW-183-01 shear block attachment insert HW-200-01 anchor sleeves at

HW-500 vertical mullion ends and match drill .191 dia. hole.

(This step is only required for design pressures above 70 psf.)

b. Attach HW-183-01 shear mlock to HW-500 vertical mullion with FS-9 fastener.

c. Install FG-5185 interior spacer gasket cut to 2" from ends and 2" gaps at horizontal to

allow for WW-352 zone plugs. (Not applicable on Dry Glazed applications)

d. Install and seal HW-325 end caps to top and bottom of HW-500 vertical mullion

screw boss with (2) FS-320 #10 x 1/2" drive screw .

HW-200-01 Anchor Sleeve

(for design pressures above 70 psf)

HW-500 Intermediate Vertical Mullion

HW-183-01 Shear Block

(4) FS-9 Fasteners

HW-338 for Jambs and HW-325 for Mullions

FG-5185 Interior Spacer Gasket

(Not applicable on Dry Glazed

applications)

Seal and tool sealant on end caps

2"

Gap dimension for

WW-352 Zone Plug

Apply sealant bed to front edge

of mullion end prior to installation

of HW-325 Mull Cap

(2) FS-320 Drive Screw

VERTICAL MULLION FABRICATION