Solder – Elecraft KIO2 User Manual

Page 3

3

Firmware Requirements

To use the KIO2, you'll need main microcontroller firmware revision 2.01 or later (the main

microcontroller is U6 on the K2 Control board). If you received new firmware as an upgrade, you can

install it now, or at the point indicated in this manual (page 10). To check your firmware revision, hold any

switch when powering up the K2. When you release the switch, the revision will be shown on the LCD.

KIO2 PC Board Assembly

i

A fine-point, temperature-controlled soldering iron (700-800 degrees F maximum) is

required to assemble the PC boards. A higher-wattage iron or one with a wide tip may damage

components, pads, or traces. We also recommended the use of a Panavise (or equivalent bench vise)

and an illuminated magnifying glass to facilitate PCB and connector assembly.

i

Install components only in the order described below. Double-check all values before soldering,

since removing parts from double-sided PC boards can be difficult.

There are three 9-pin "D" connectors (type DB9F) supplied with the kit, two female and one male. The

two types both have solder cup terminations on one side. On the other side, the male connectors have pins

while the females have sockets. Locate one of the female connectors for use at J1 on the KIO2 board.

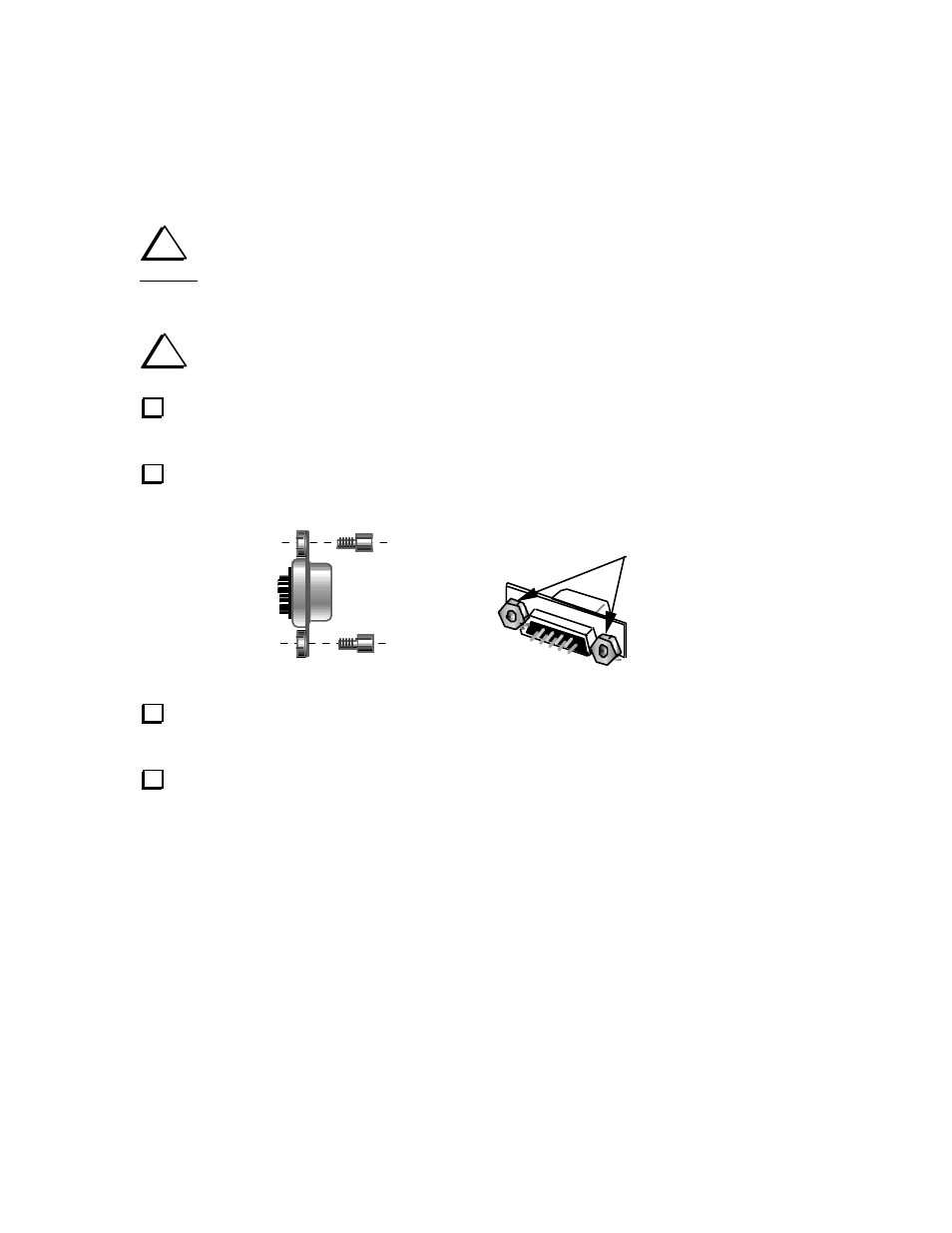

Locate two male/female hex standoffs and two brass nuts. Temporarily insert the standoffs through J1

from the socket side, and secure them hand-tight only with the brass nuts as shown in Figure 1 (A).

SOLDER

(A)

(B)

Figure 1

Clamp J1 into a padded vise with the brass nuts facing up. An alternative is to temporarily attach J1 to

the K2 top cover in its intended location, labeled "AUX I/O." Either method will hold J1 firmly while

soldering in the next step.

Solder the brass nuts to the D-connector (J1) at the locations shown in Figure 1 (B). This is best

accomplished by using the tip of your soldering iron to heat both the nut and flat portion of J1 at the same

time. If you cannot melt solder onto the brass nut after heating this junction for about 8-10 seconds, use a

larger iron. Avoid overheating the connector, which could melt the plastic surrounding the solder cups.