Edge Lighting Kurve Display Sign User Manual

Page 2

NOTE:

It is recommended another person hold the fixture while

the electrician connects the power to the fixture.

2

ANCHOR

F

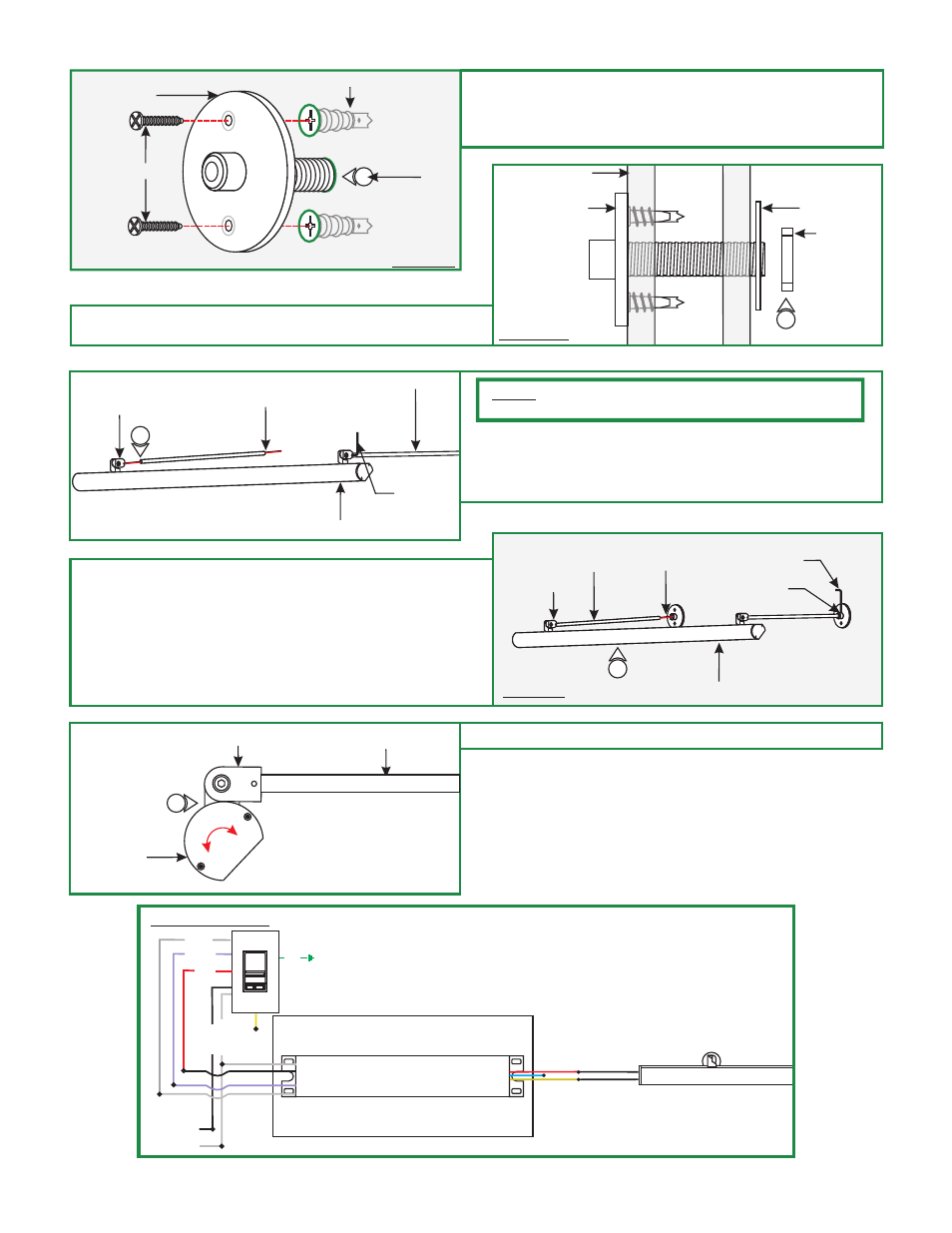

8: Insert the base nipple into the hole and secure using

the two #8 screws provided.

9: Repeat step 8 for the other bases (without the nipple).

8

DRYWALL

#8 SCREW

NIPPLE

WALL

10: Power Feed Base Only: secure from behind the wall

using the large washer and nut.

G

SIDE VIEW

POWER

FEED BASE

WASHER

NUT

10

H

11: Feed the stem into the fixture hinges and secure by

tightening the M3 set screw with the 1.5MM Allen wrench.

For the power feed hinge carefully run the power

wires through the stem.

11

STEM

FIXTURE BODY

POWER

WIRES

HINGE

1.5MM ALLEN

WRENCH

12: While feeding the power wires into the base, slide the

stems into the bases. Secure the stems in place by

t

13: Make all the proper wire connections. Refer to the power

supply instructions for additional information.

(General wiring diagram below).

ightening the M4 set screw on the bases with 2MM Allen

wrench.

I

DRYWALL

FIXTURE BODY

STEM

HINGE

POWER

WIRES

2MM ALLEN

WRENCH

M4 SET

SCREW

J

14: Rotate the fixture head to properly luminate the sign.

STEM

HINGE

14

FIXTURE

HEAD

ANGLE/KURVE DISPLAY SIGN

GENERAL WIRING

BASE

INPUT

120VAC

GROUND

LIGHTOLIER:

ZP600FAM120

CONTROLLER

WHITE (NEUTRAL)

BLACK (HO

T)

RED 120VAC

(HOT)

GRAY (1-10V)

PURPLE (1-10V)

input 120VAC

WH (N)

BK (L)

input 0-10V

PUR

GRY

RED (24VDC+)

BLUE (RETURN-)

YELLOW (DIM RETURN-)

POWER SUPPLY (1)

PSB-96-010-24VDC

24VDC

12