Bio-Rad PROTEAN II XL Cell User Manual

Page 35

29

Section 12

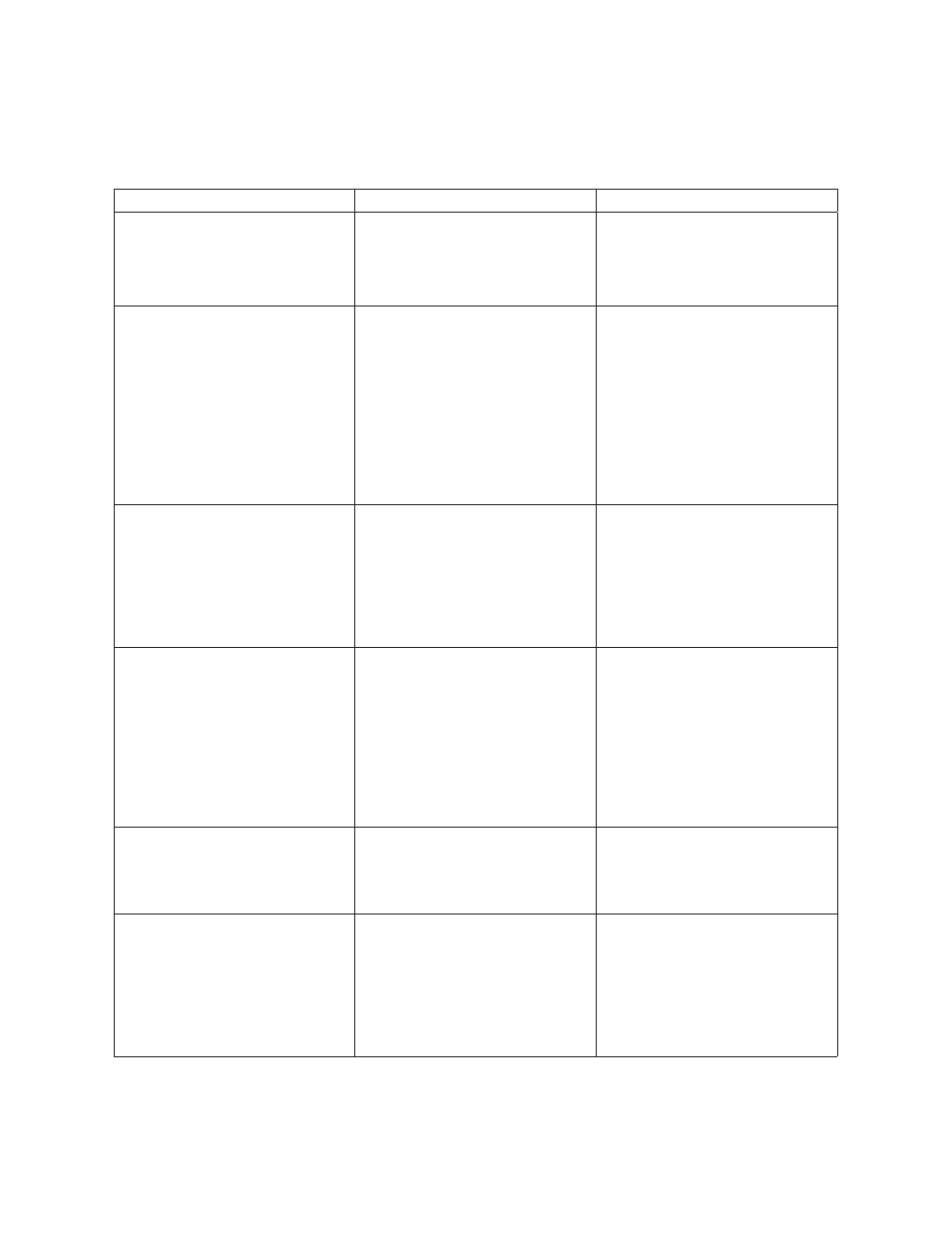

Troubleshooting Guide – PAGE, SDS-PAGE, 2-D IEF/SDS-PAGE

Problem

Cause

Solution

1. “Smile” effect — band pattern

curves upward at both sides

of the gel.

• Center of the gel running

hotter than either side

• Power conditions excessive

• Fill inner core with coolant

• Circulate coolant at

10-15 °C

• Decrease power setting

2. Diffuse tracking dye.

• Decomposition of sample

solution and/or buffer stock

solutions

• Diffusion

• Prepare fresh reagents —

maximum shelf life of aque-

ous solutions is 30 days at

4 °C for buffer and monomer

stocks

• If protein bands are diffuse as

well as to the tracking dye,

increase current by 25–50%

and/or increase % T of

resolving gel*

3. Vertical streaking of protein.

• Sample overload

• Sample precipitation

• Dilute sample, selectively

remove predominant protein

in the sample, or reduce

current by about 25% to

minimize streaking

• Centrifuge sample or de-

crease % T of resolving gel*

4. Horizontal streaking (2-D

gels).

• Incomplete solubilization prior

to first dimension

• Interfering nucleic acids in

sample

• If urea/nonionic detergent is

not sufficient, use SDS as in

Ref. 15.5-2. Centrifugation

of sample may be necessary

(up to 100,000 x g for

30 minutes) to remove

undissolved particulates

• Treat sample with DNase or

RNase as in Ref. 15.5-1

5. Broad or diffuse protein

bands or spots (2-D).

• Diffusion due to slow

migration

• Chemical changes due to

ionic contaminants in urea

• Increase current by 20%

• Deionize urea

6. Lateral band spreading.

• Diffusion out of the wells prior

to turning on the current

• Diffusion during migration

through the stacking gel

• Minimize the time between

sample application and

power start-up

• Increase % T of stacking gel

to 4.5% or 5% T, or increase

current by 25% during

stacking*