Bio-Rad PROTEAN II XL Cell User Manual

Page 26

20

5. Buffer is then pumped from the lower to the upper buffer chamber. As the upper chamber fills, buffer will

overflow through the port on the core back into the lower buffer chamber.

The buffer flowing through the tubing and pump is electrically active. For this reason, handle the

tubing carefully when the power supply is on. Do not touch any exposed liquid with the power

supply on. Tube connections should be made with the power supply turned off. Both the

recirculation pump and the recommended power supplies must be ground isolated by design

to minimize the potential for shock hazard. However, working around high voltage equipment in

a laboratory environment is potentially dangerous. As a result, it is the user's responsibility to

always exercise care in setting up and running electrophoresis instruments. If a liquid leak

occurs, always turn off the power supply before correcting the problem.

Note: Recirculation can only be used with continuous buffer systems (i.e., systems in which the

anode buffer and cathode buffer are the same).

8.2 Cooling Options

The cooling core may be used in any of the following ways:

1. The core can be connected to any circulating cooler. Any common anti-freeze or ethylene:glycol (20:80)

may be circulated through the core. Do not use ethanol or methanol for coolant. For most SDS-PAGE

and 2-D applications temperature should be set between 10 and 15 °C. For some specialized

applications employing native or non-denaturing gel systems, in which temperature sensitive enzymes or

other labile proteins are to be separated, the system can be cooled to 2-4 °C. For these applications,

greatest heat transfer efficiency is achieved by circulating coolant through the core at 2 °C and filling the

lower buffer chamber to the top of the slab gels. The lower buffer is continually circulated by stirring.

2. The core may be filled with coolant and the circulation ports plugged off with the core caps. The coolant

will act as a heat sink during electrophoresis. This option works especially well for SDS-PAGE.

3. Distilled tap water may be circulated through the core.

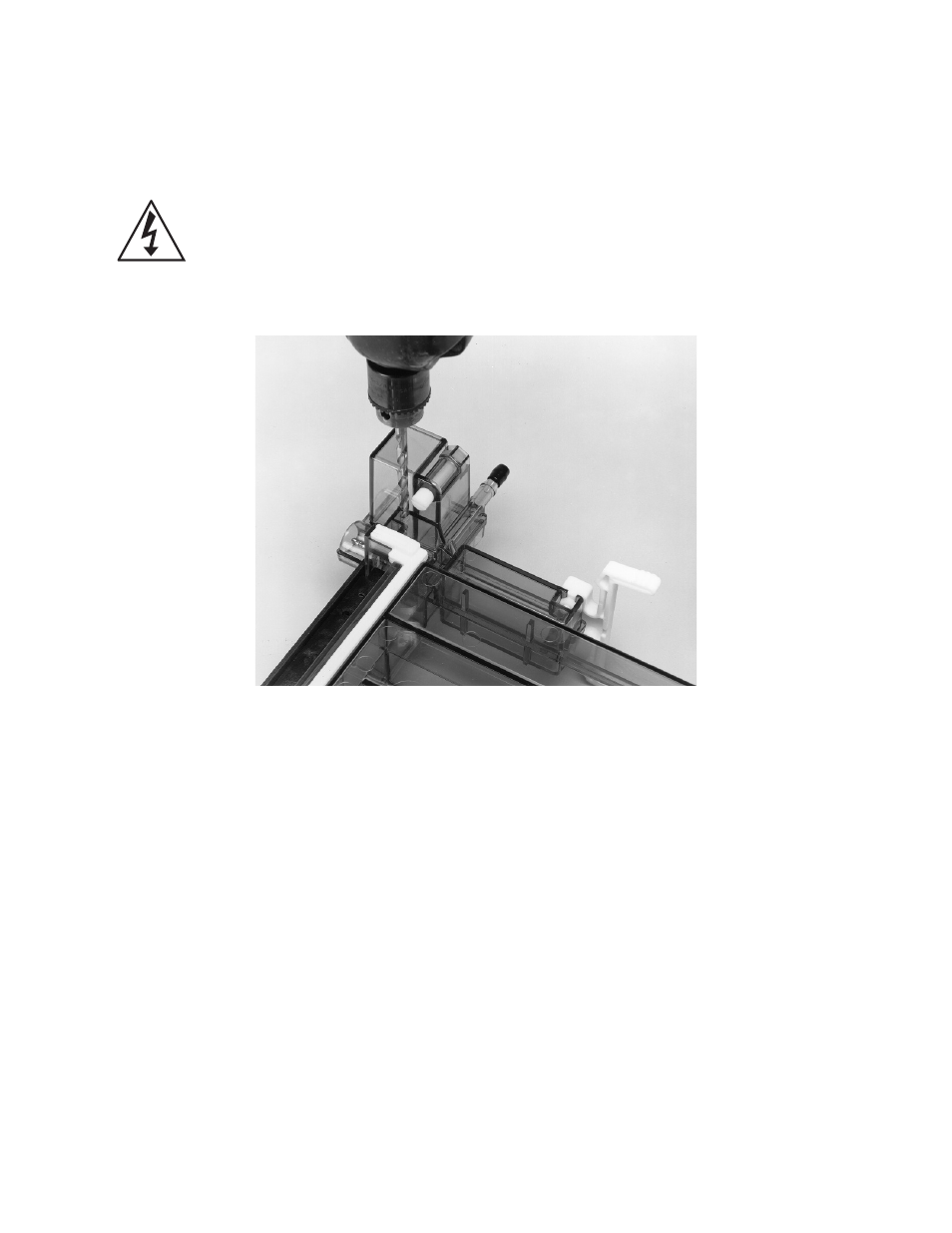

4. Temperature of the coolant can be monitored by placing a thermometer through one of the ports in the

lid of the PROTEAN II xi cell. The temperature of the upper and lower buffers will equilibrate to the

temperature of the coolant in about 1/2 hour. Remove the tab in the lid as in Section 8.1, step 1.

5. During periods of non-use, the cooling core can be left filled with coolant or water and capped.