Install secondary seed hoses, Caution – Great Plains NTA3010 Predelivery Manual User Manual

Page 32

30

NTA3010, NTA3510 and ADC

Great Plains Manufacturing, Inc.

160-220M

11/06/2008

Install Secondary Seed Hoses

Secondary seed hose is 1 inch (2.5cm) in diameter and

is delivered in 100-foot rolls:

817-039C PVC SEED HOSE 1 IN/FT

Cut and route secondary hoses to connect each opener

to a distribution tower. Port Assignment tables are found

on page 32 through page 35.

69. Start with Tower 1 (far left tower), Port 1. Port 1 is the

tower port closest to the center of the tower mount-

ing plate

. Ports are numbered in ascending order

clockwise around the tower.

Note: It may aid secondary hose installation, and will aid

any later blockage detector installation, to mark the

top of the tower cap with Port and Row numbers.

Use a washable felt-tip marker to avoid paint dam-

age. The tables in this manual do not include Block-

age sensor assignments, because the numbering

is different depending on seed monitor model.

70. Consult the Port Assignment table for this model drill,

noting the Hose Length for this Tower and Port, and

the Opener (Row) assigned.

For example, on a 7

1

⁄

2

in spacing NTA3510, the hose

that connects Tower 1, Port 1 is about 59 inches in

length, and connects to the 10th Opener.

71. Measure the expected hose length and mark

hose

with grease pencil or tape.

72. At the Tower, loosen, but do not remove, perimeter

bolts

holding tower halves together.

73. Insert hose

into the current Port. Push hose into

port until seated against the stop.

74. Route hose

over implement frame as shown in

the Figure that accompanies your Port Assignment

table.

Route seed hoses to prevent rubbing on sharp

edges or damage when the implement is raised, low-

ered, folded or unfolded.

Allow enough hose slack for implement folding and

down-flex, but not so much that there are sags in

which seeds can collect.

75. When you are satisfied you have the proper hose

length, cut hose

IMPORTANT !

Do not cut hose until routed over implement. Lengths

in table are approximate. Actual lengths may vary

from implement to implement.

Make clean cuts. Any snags or frays at the tower end

can imbalance seed delivery.

Note: Some hoses connect openers and towers on dif-

ferent frame sections.

Note: Note, from routing Figure, that some hoses are

routed through hose holders on implement frame

to prevent dragging or catching.

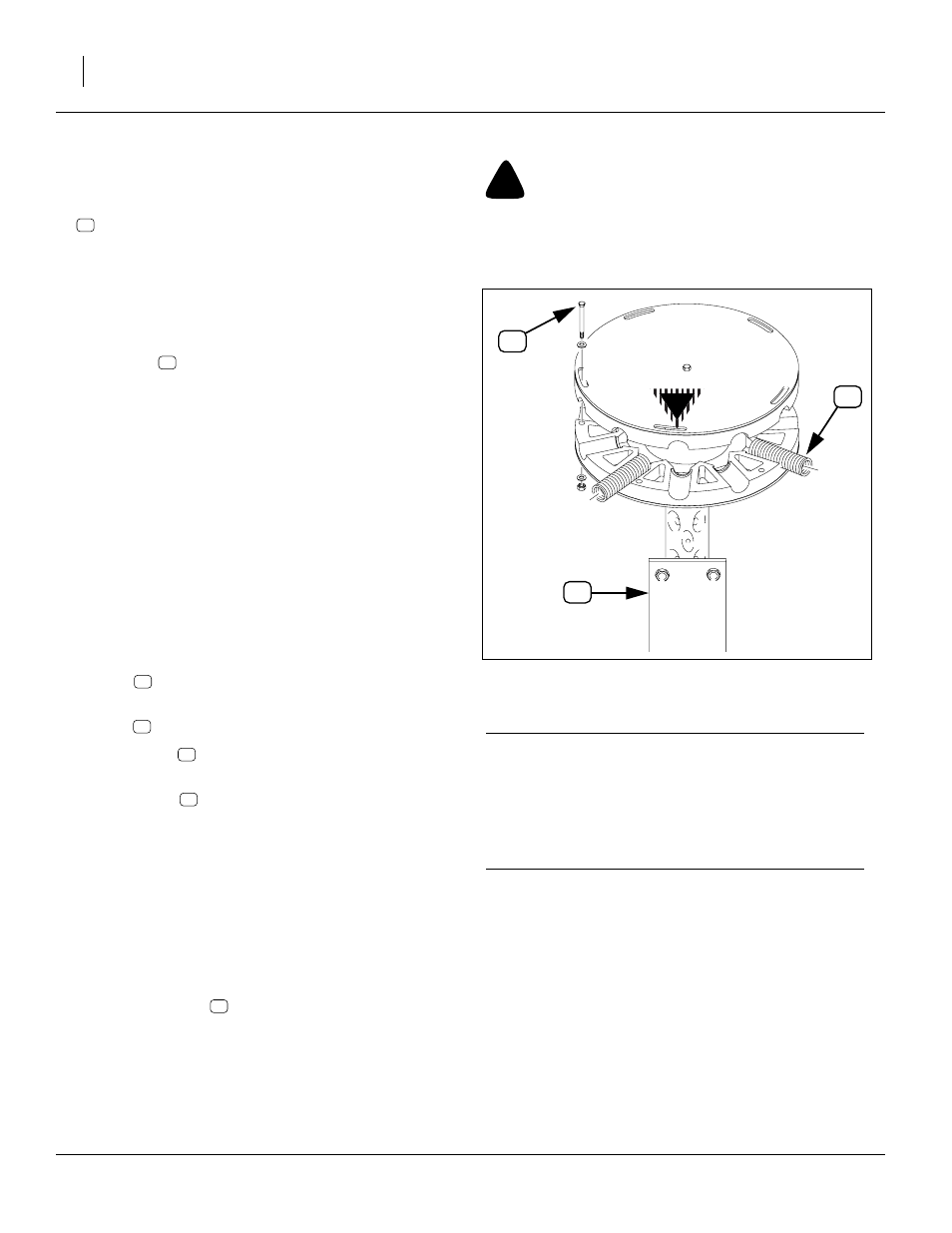

Figure 41

Secondary Hose at Tower

28462

1

PORT

2

3

4

!

CAUTION

To avoid serious injury or death from crushing, make sure

transport locks are in place, the drill is sufficiently blocked up,

and the tractor is shut off with the key removed before attempt-

ing to route hoses to Towers and openers.