Install lift-assist cylinders – Great Plains NTA3010 Predelivery Manual User Manual

Page 19

Great Plains Manufacturing, Inc.

Air Drill Assembly

17

11/06/2008

160-220M

Refer to Figure 14 on page 16 and Figure 15

54. Select the left gauge wheel cylinder, which is:

161-112K NTA DEPTH STOP VALVE ASSY and

810-221C CYL REP 4.25X12X1.5 ROD (TIE)

55. Remove and save the base-end pin hardware:

805-017C PIN COTTER 3/16 X 1 3/4 PLT

804-029C WASHER FLAT 1 SAE

805-239C PIN CLEVIS 1 X 3 5/16 HRD PLT

56. With the depth stop on top of the cylinder, pin the

base end of the cylinder

to the left wing

eyebolt

. Secure with clevis pin

, washer

and

cotter pin

. Hoses are routed at step 65.

57. Remove and save the rod-end pin hardware:

805-017C PIN COTTER 3/16 X 1 3/4 PLT

804-029C WASHER FLAT 1 SAE

805-159C PIN CLEVIS 1 X 3 1/8 GR5 PLT

58. Pin the rod end of the cylinder

to the left gauge

wheel lug

. Loosely hold in place with clevis pin

only. Leave rod end washer

cotter pin

off, to

ease the later task of hydraulic charging.

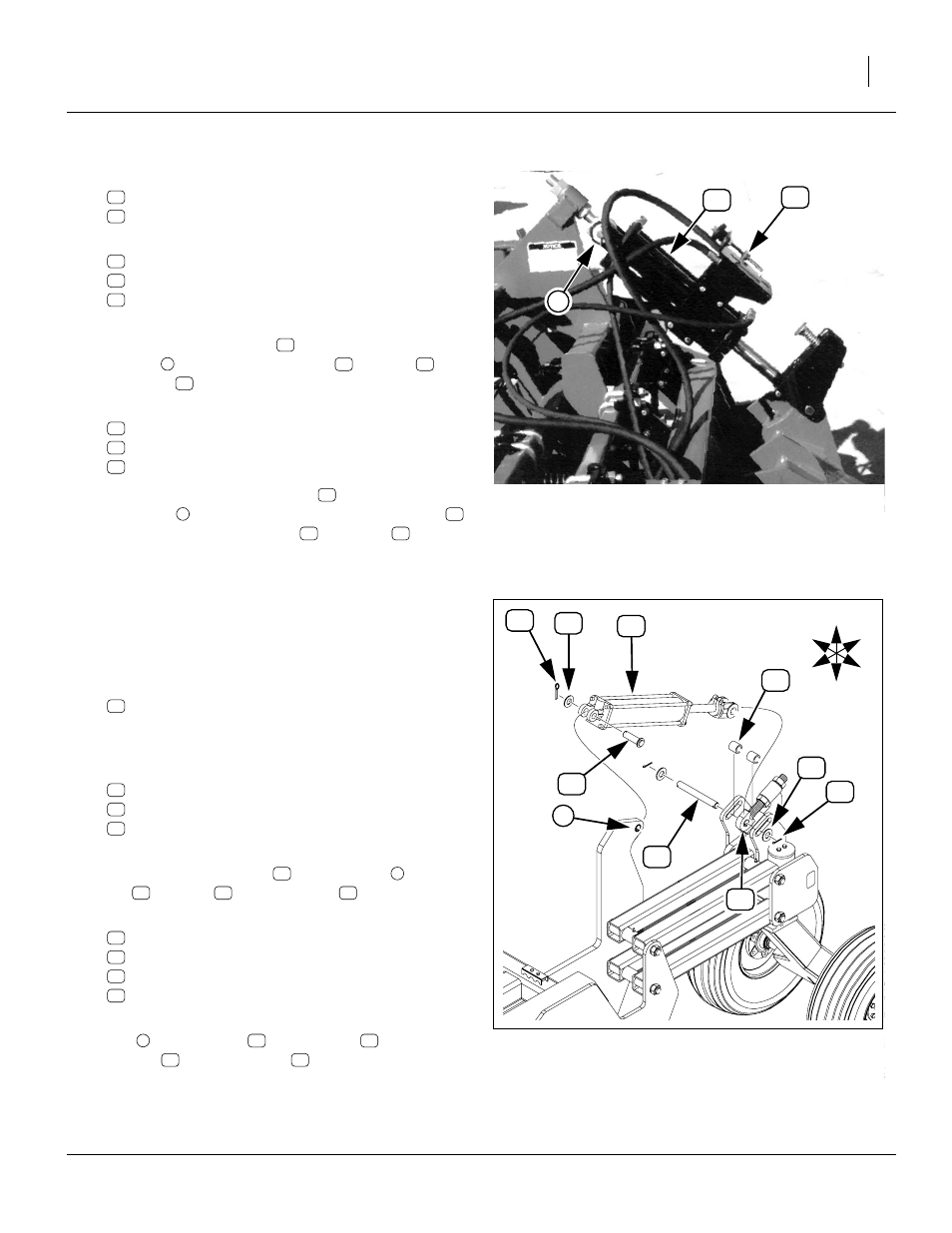

Install Lift-Assist Cylinders

Start with the left caster assembly. Cylinders are identical

for both sides.

59. At the center section, untie the lift-assist cylinders.

Select one:

810-333C CYL REP 4.5X12X1.5 ROD 22.25L

The gauge-wheel cylinders for the wings are labeled

4

1

⁄

2

in bore re-phasing.

60. Remove and save the base-end pin hardware:

61. With the cylinder ports oriented up, pin the base end

of the lift-assist cylinder

to the top lug

, using a

pin

, washer

62. Locate, or remove and save the rod end hardware:

63. Pin the rod end of the lift-assist cylinder to the eye-

bolt

using the pin

washer

and cotter pins

hydraulic charging. Hoses are routed at step 65.

64. Repeat step 59 through step 63 for right lift-assist-

wheel arm.

Figure 15

Left Gauge Wheel Cylinder

16220

2

Figure 16

Lift-Assist Cylinder

28459

3

U

D

F

B

L

R